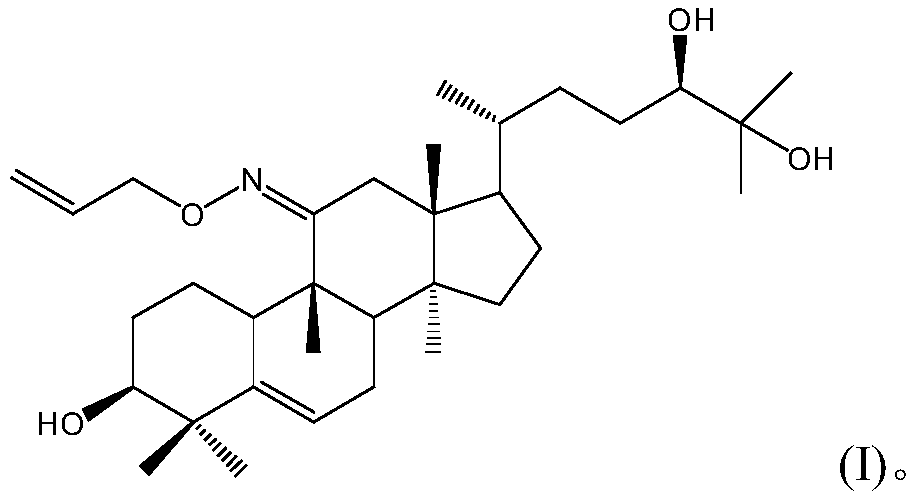

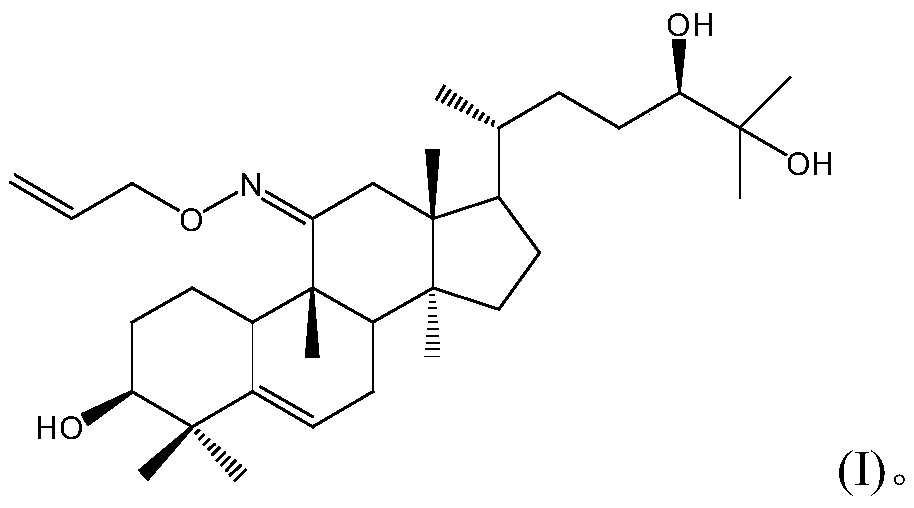

11-O-mogrol oxime ether derivative serving as oral liquid antioxidant additive, and anti-oxidative and anti-aging oral liquid

A technology of Luo Han Guo and oral liquid, applied in the fields of antivirus, food science, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

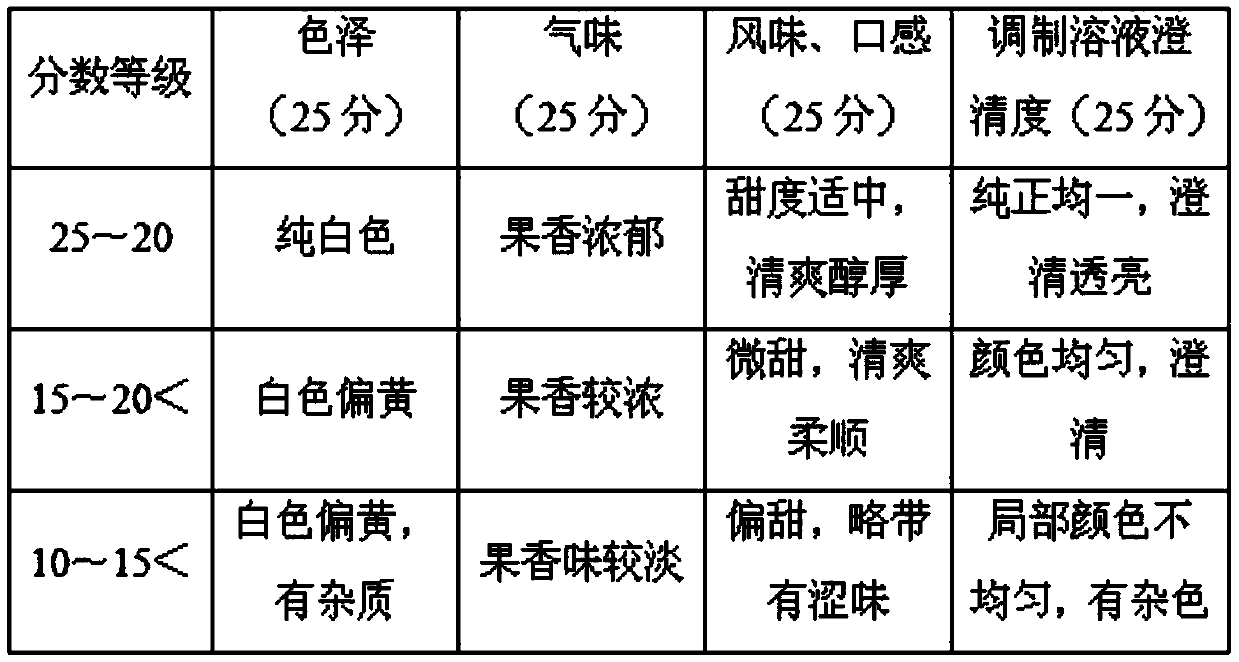

Examples

preparation example Construction

[0037] Preparation Example 1 The preparation of formula (I) compound

[0038](1) Oximation and post-treatment: Take 23.8g of 11-O-mogrogol, dissolve it in 150ml of anhydrous methanol, add 4.5g of hydroxylamine sulfate (containing 0.055mol of hydroxylamine) and 20.2g of triethylamine, and react under reflux at 70°C for 5 hours , after the completion of the silica gel TLC test reaction, concentrated under reduced pressure until the solid content of the concentrated solution was 25%, cooled the concentrated solution to a temperature of 10°C, stirred at a speed of 10r / min, crystallized for 18 hours, suction filtered, and dried to obtain 11- Oxime-Mogrosanol 21.6g.

[0039] (2) Etherification and post-treatment: Dissolve 20.2 g (0.04 mol) of 11-oxime-mogrosanol obtained in step (1) in 110 ml of DMF, add 3.14 g of allyl chloride and 0.08 g of sodium tert-butoxide, and react at 5°C for 5 hours. Silica gel TLC test After the reaction is over, pour the reaction solution into 1000ml o...

preparation example 2

[0041] Preparation example 2 Preparation of Monk Fruit Decolorized Concentrated Juice

[0042] (1) Juicing and cold extraction of fresh fruit: After washing 200kg of Luo Han Guo fresh fruit, squeeze it with a juicer, and extract the pomace with 600kg of ice water at 8°C twice for 0.5 hours each time. The water extracts are combined to obtain Luo Han Guo juice;

[0043] (2) Enzymolysis, boiling, and centrifugation: adjust the pH value of the Luo Han Guo fruit juice obtained in step (1) to 9 with a saturated aqueous solution of calcium hydroxide, then add 0.1 kg of alkaline protease preparation, and perform enzymatic hydrolysis for 1.5 hours at 25°C , and then, heat and boil the enzymolysis liquid at 90°C for 0.5h, rapidly cool it to 30°C at a speed of 2°C / min, and centrifuge to obtain the enzymolysis centrifugation liquid;

[0044] (3) desalination, dealkalization: with step (2) gained enzymolysis centrifugal liquid, the flow rate of above post is 1.5BV / h, goes up 001 * 7 ty...

preparation example 3

[0047] Preparation example 3 Okra Sauce Preparation

[0048] a. Extraction: 50 kg of fresh okra was washed with water, crushed with a beater, added 300 kg of pure water, heated to 85° C., stirred and extracted for 2 hours, filtered to obtain okra extract;

[0049] b. Purification: Cool the okra extract to room temperature, add complex enzymes (0.06 kg each of pectinase, protease and cellulase), enzymolyze at 35°C for 4 hours, and inactivate the enzyme at 90°C. Add 0.1 kg of activated carbon, stir for 1 hour to decolorize, filter with a ceramic membrane, and concentrate the ceramic membrane filtrate under reduced pressure at 70°C and -0.08MPa to a sugar content of 40brix to obtain 9.6 kg of okra juice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com