Conductive silver paste applied to ceramic filter and preparation method thereof

A technology of ceramic filter and conductive silver paste, which is applied in equipment for manufacturing conductive/semiconductor layer, cable/conductor manufacturing, circuit, etc. Focus on the problems of influence, insufficient compactness of the conductive layer, etc., to achieve the effect of increasing the intermolecular force, the density of the conductive layer, and the increase of the aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of the conductive silver paste that is applied to ceramic filter of the present invention comprises the following steps:

[0030] Step 1: Add potassium chloride, aluminum sulfate, and polyvinylpyrrolidone (average molecular weight: 1,300,000) to 540 mL of ethylene glycol, mix well, heat to 160°C and keep it warm for 30 minutes to remove excess water in the ethylene glycol and obtain the first a mixed solution;

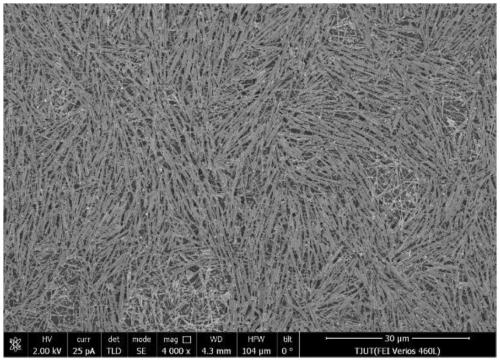

[0031] Step 2: Add 60 mL of ethylene glycol solution of silver nitrate to the first mixed solution obtained in step 1, and mix well to obtain a second mixed solution; the second mixed solution is reacted at 160° C. for 4 hours, so that the second mixed solution The silver ions in the solution are reduced by ethylene glycol to generate nano-silver rods, and then the whole reaction system is cooled to room temperature to obtain the third mixed solution containing nano-silver rods; the third mixed solution is poured out after being cent...

Embodiment 2

[0037] A kind of preparation method of the conductive silver paste that is applied to ceramic filter of the present invention comprises the following steps:

[0038] Step 1: Add potassium chloride, potassium bromide, aluminum sulfate, and polyvinylpyrrolidone (average molecular weight: 1,300,000) to 540 mL of ethylene glycol, mix well and heat to 150°C for 30 minutes to remove excess Moisture to obtain the first mixed solution;

[0039] Step 2: Add 60 mL of silver nitrate in ethylene glycol solution to the first mixed solution obtained in step 1, and mix well to obtain a second mixed solution; the second mixed solution is reacted at 150° C. for 4 hours, so that the second mixed solution The silver ions in the solution are reduced by ethylene glycol to generate nano-silver rods, and then the whole reaction system is cooled to room temperature to obtain the third mixed solution containing nano-silver rods; the third mixed solution is poured out after being centrifuged at a speed...

Embodiment 3

[0045] A kind of preparation method of the conductive silver paste that is applied to ceramic filter of the present invention comprises the following steps:

[0046] Step 1~step 2: same as step 1~step 2 of embodiment 1;

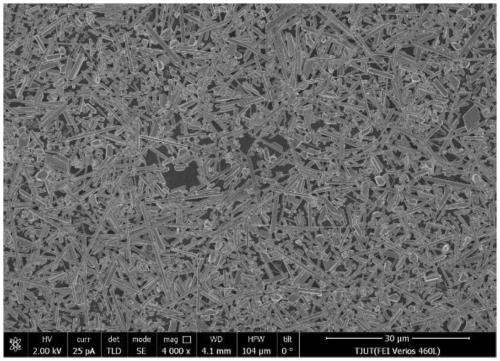

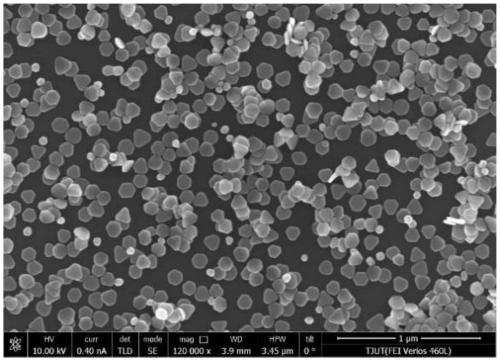

[0047] Step 3: Measure 200mL of the ethanol dispersion of silver nanorods obtained in step 2 (wherein the concentration of nanosilver rods is 10mg / mL), 200mL of ethanol dispersions of nanosilver flakes (wherein the concentration of nanosilver flakes is 10mg / mL), Mix well to obtain the first dispersion; then add a high-boiling organic solvent (0.72g terpineol and 0.18g butyl carbitol acetate) to the first dispersion, and mix well under the conditions of 0.09MPa and 60°C Ethanol was distilled off under reduced pressure until no new ethanol was distilled off to obtain the second dispersion;

[0048] Step 4: Add 0.11 g of lead-free glass powder and 0.26 g of ethyl cellulose as a thickener to the second dispersion obtained in Step 3, and mix well to obtain conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com