Preparation method of GaN-based planar Schottky varactor

A technology of varactors and base planes, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as inability to meet high power requirements, achieve the effects of reducing parasitic capacitance, reducing errors, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of a GaN-based planar Schottky varactor, the preparation method comprising the steps of:

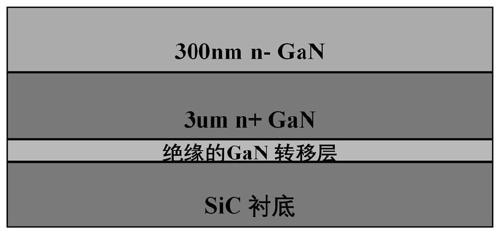

[0037] 1) GaN epitaxial wafers with a diameter of 2 inches of silicon carbide (SiC) substrates (which can improve the crystallization quality of GaN epitaxial layer materials and reduce dislocation density), such as figure 1 As shown, the epitaxial wafer structure from bottom to top is: 360um thick SiC substrate, insulating GaN transition layer, n-type heavily doped GaN layer with a thickness of 3um, and a doping concentration of 1*10 19 / cm -3 , an n-type lightly doped GaN layer with a thickness of 300nm, and a doping concentration of 2*10 17 / cm -3 ;

[0038] 2) Positioning calibration - production of alignment marks:

[0039] The lithography equipment uses a contact or stepper exposure machine to design an alignment pattern, and uses electron beam evaporation Ti / Au to complete the transfer of the alignment mark shown in the pattern on the epitaxial waf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com