Preparation method and application of porous foamed nickel loaded manganese oxide nanosheet array

A nanosheet array and porous foam technology, which is applied in the field of supercapacitor electrode material preparation, can solve the problems of reduced capacitor performance, low ionic conductivity, low electronic conductivity, etc. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

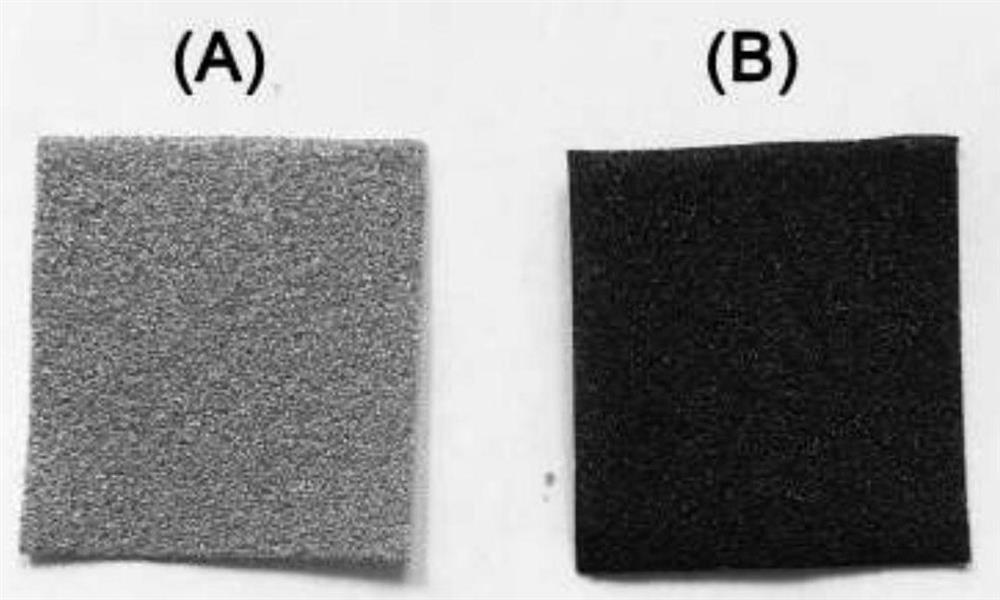

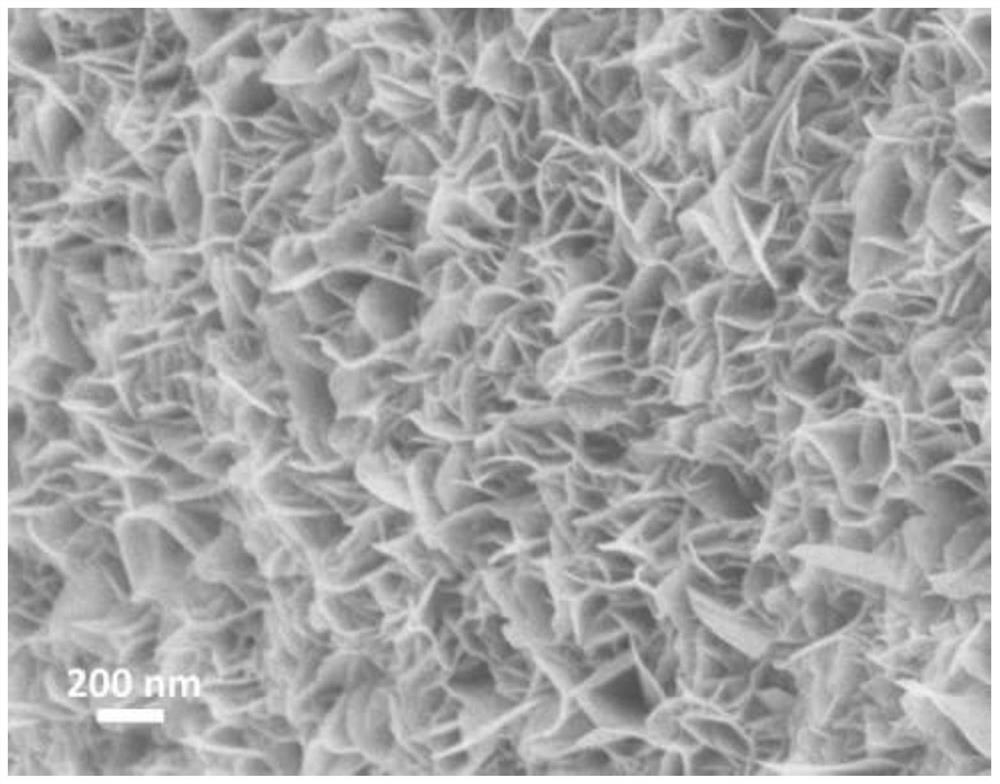

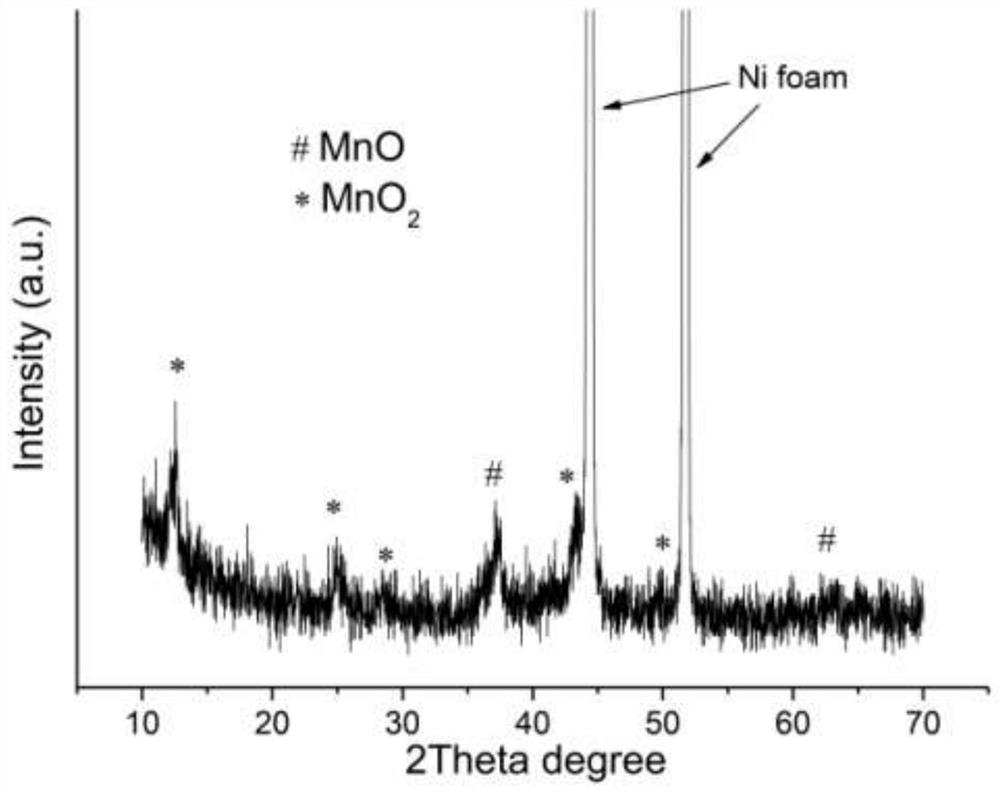

[0030]Preparation of porous Ni foam-supported MnO nanosheet arrays:

[0031] 1. Soak 2cm×2cm nickel foam in acetone, ultrasonic 10min to remove the grease on the surface, then take out the nickel foam, transfer it to a hydrochloric acid solution with a concentration of 6mol / L, continue ultrasonication for 3 minutes to remove the surface oxide layer, and then take it out Transfer to a pure ethanol solution and continue sonication for 10 minutes. Repeat the above steps, wash continuously for 3 times and dry in a vacuum oven at 60°C to obtain a foamed nickel mesh with a clean surface.

[0032] 2. Weigh 10mmol of KMnO 4 (1.58 g) was dissolved in deionized water with a volume of 30 mL, and after ultrasonic treatment for 5 minutes to completely dissolve, add the above-mentioned piece of cleaned foam nickel mesh, transfer it to a hydrothermal reaction kettle with a volume of 50 mL, and heat to 160 ° C. Keep warm for 12 hours. Take it out after the temperature of the reaction is lo...

Embodiment 2

[0039] Preparation of porous Ni foam-supported MnO nanosheet arrays:

[0040] 1. Soak 3cm×3cm nickel foam in acetone, ultrasonic 10min to remove the grease on the surface, then take out the nickel foam, put it into a hydrochloric acid solution with a concentration of 4mol / L, continue ultrasonication for 3.5 minutes to remove the surface oxide layer, and then take it out Transfer to a pure ethanol solution and continue sonication for 10 minutes. Repeat the above steps, wash continuously for 3 times and dry in a vacuum oven at 60°C to obtain a foamed nickel mesh with a clean surface.

[0041] 2. Weigh 20mmol of KMnO 4 (3.16 g) was dissolved in deionized water with a volume of 40 mL, and after ultrasonic treatment for 5 minutes to completely dissolve, add the above-mentioned piece of cleaned foam nickel mesh, transfer it to a hydrothermal reaction kettle with a volume of 50 mL, and heat to 150 ° C. Keep warm for 10 hours. Take it out after the temperature of the reaction is lo...

Embodiment 3

[0044] Preparation of porous Ni foam-supported MnO nanosheet arrays:

[0045] 1. Soak 4cm×4cm nickel foam in acetone, ultrasonic 10min to remove the grease on the surface, then take out the nickel foam, transfer it to a hydrochloric acid solution with a concentration of 5mol / L, continue ultrasonication for 4 minutes to remove the surface oxide layer, and then take it out Transfer to a pure ethanol solution and continue sonication for 10 minutes. Repeat the above steps, wash continuously for 3 times and dry in a vacuum oven at 60°C to obtain a foamed nickel mesh with a clean surface.

[0046] 2. Weigh 20mmol of KMnO 4 (3.16 g) was dissolved in deionized water with a volume of 60 mL, and after ultrasonic treatment for 5 minutes to completely dissolve, add the above-mentioned piece of cleaned foam nickel mesh, transfer it to a hydrothermal reaction kettle with a volume of 100 mL, and heat to 150 ° C. Keep warm for 12 hours. Take it out after the temperature of the reaction is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com