Nanoscale calcium hydroxyphosphate/calcium hydrophosphate and preparation method thereof

A technology of calcium hydroxyphosphate and calcium hydrogen phosphate, which is applied in the chemical industry, can solve the problems of product effect improvement and various application limitations, the inability to prepare calcium hydroxyphosphate or calcium hydrogen phosphate, and the high cost of the preparation method, so as to meet the needs of ecological development , small impact on product quality and animal health, and the effect of improving particle size and distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

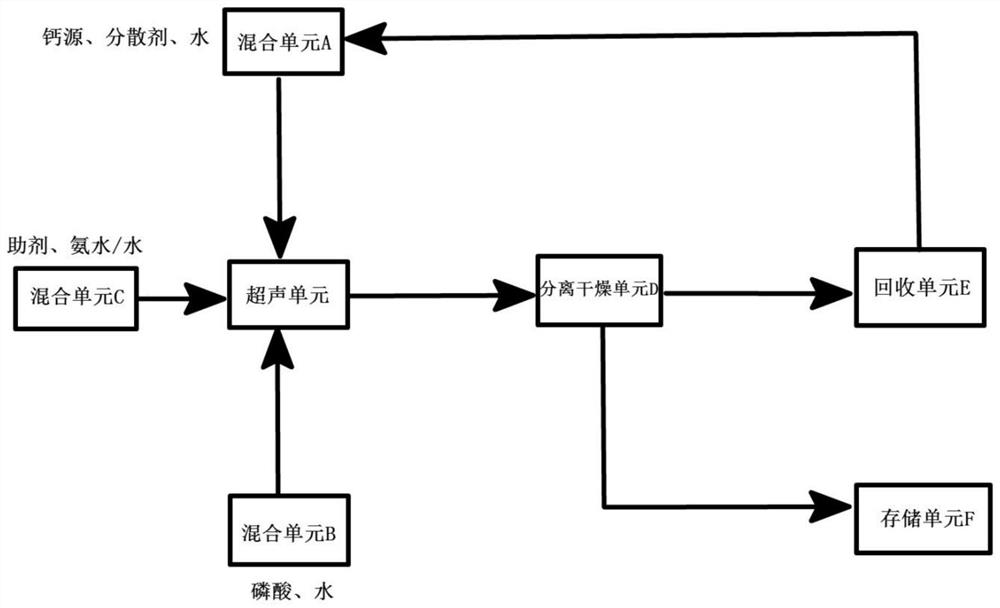

Image

Examples

Embodiment 1

[0052] Embodiment 1 calcium source stable emulsion preparation

[0053] Take 300g of calcium oxide uniform powder and a small amount of water to make a wet solid. The obtained wet solid (do not need to be wet when calcium hydroxide is used as the calcium source) and 250g of maltodextrin are alternately added to 1200ml of water in batches, stirred to obtain a white emulsion, and 50g of Stir the glacial acetic acid evenly, and the obtained calcium salt stable emulsion 1 is ready-to-use.

[0054] Take 300g of calcium oxide uniform powder and a small amount of water to make a wet solid. The obtained wet solid (do not need to be wet when calcium hydroxide is used as the calcium source) and 45g of maltodextrin are alternately added to 1200ml of water in batches, stirred to obtain a white emulsion, and 5g of The glacial acetic acid was stirred evenly, and the obtained stable white emulsion was calcium source stable emulsion 2.

[0055] Take 600g of calcium oxide uniform powder and a...

Embodiment 2

[0056] Preparation of embodiment 2 phosphoric acid solution and reaction base liquid

[0057] Phosphoric acid or wet-process phosphoric acid is added with chemical agents to precipitate and remove impurities to obtain phosphoric acid solution. After measuring As<10PPM, Pb<10PPM, F<0.2%, adjust the concentration of phosphoric acid solution to 10wt%, 20wt%, 25wt%, 45wt%, 50wt% , 60wt% for use.

[0058] Reaction base liquid C1 configuration:

[0059] Dilute ammonia water is used to adjust 0.01wt% antistatic additive dodecyltrimethylammonium chloride aqueous solution to obtain a base solution C11 with a pH of 10.5 to 12;

[0060] Dilute ammonia water is used to adjust 0.1wt% antistatic additive dodecyltrimethylammonium chloride aqueous solution to prepare a base liquid solution C12 with a pH of 10.5 to 12;

[0061] Dilute ammonia water is used to adjust 1 wt% aqueous solution of dodecyltrimethylammonium chloride, an antistatic additive, to obtain a base liquid solution C13 with ...

Embodiment 3

[0067] Preparation of Nano Calcium Hydroxyphosphate

[0068] Get 705.3g calcium source stable emulsion embodiment gained calcium source stable emulsion 3, phosphoric acid solution and reaction base liquid are configured by embodiment gained 60wt% phosphoric acid solution 735.1g for use, 150ml reaction base liquid C13 is transferred to reaction container in advance, at 200KHz frequency , 0.55W / cm 2 Under the ultrasonic radiation atmosphere of power density, stable calcium source emulsion and phosphoric acid solution are added dropwise to the reaction base liquid at the same time, and the dropwise addition is completed within 15 minutes. The system pH is continuously tracked during the dropping and temperature control reaction process, and the pH of the system is controlled with ammonia water> 10.5 , the temperature control uses chilled water circulation to control the reaction temperature at 15 ° C, and the temperature control continues to react for 180 min in an ultrasonic rad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com