Preparation and application of polyethyleneimine modified reversed-phase/strong anion exchange mixed-mode polymer

A mixture and cross-linking agent technology, applied in the direction of anion exchanger materials, anion exchange, inorganic anion exchangers, etc., can solve the problems of poor retention capacity of polar substances, low exchange capacity, complicated preparation, etc., and achieve uniform particle size , simple preparation process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Dissolve 90mg of azobisisobutyronitrile in 1.69g of 1-dodecanol, 4.55mL of toluene, 4.55mL of divinylbenzene, and 1.6mL of diethylaminoethyl methacrylate, sonicate for 10min, pass Nitrogen deoxygenated for 10 minutes to prepare solution A;

[0029] (2) 80mg nano-SiO 2 Disperse in 10mL of water and ultrasonically disperse for 10min to prepare solution B. Take 4mL of solution A and add it to 10mL of solution B, homogenize it with a homogenizer at 6000rpm for 1min, seal it, and put it in a water bath at 70°C for polymerization for 16h to obtain PDEAEMA-SiO 2 Complex.

[0030] (3) PDEAEMA-SiO 2 Disperse and soak in 10% hydrofluoric acid for 12 hours to obtain PDEAEMA microspheres.

[0031] (4) Disperse 2.0g of PDEAEMA microspheres in 20mL of methanol, stir magnetically, add 2mL of BDDE, and react at 80°C for 3h. After the reaction, filter and wash with ethanol to obtain PDEAEMA-BDDE polymer microspheres with epoxy end groups.

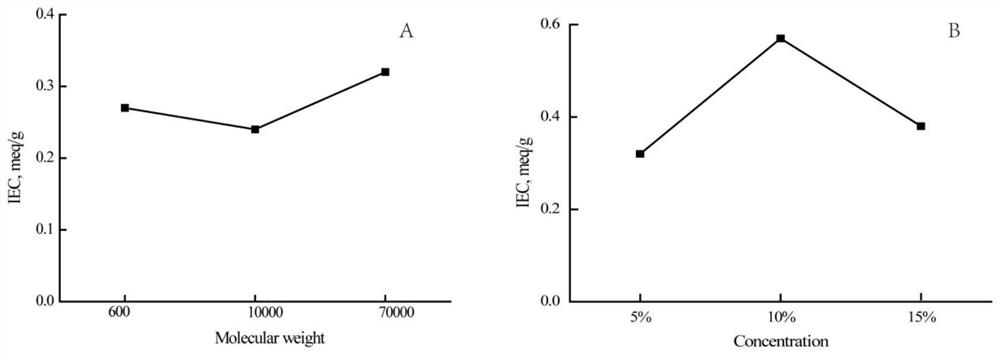

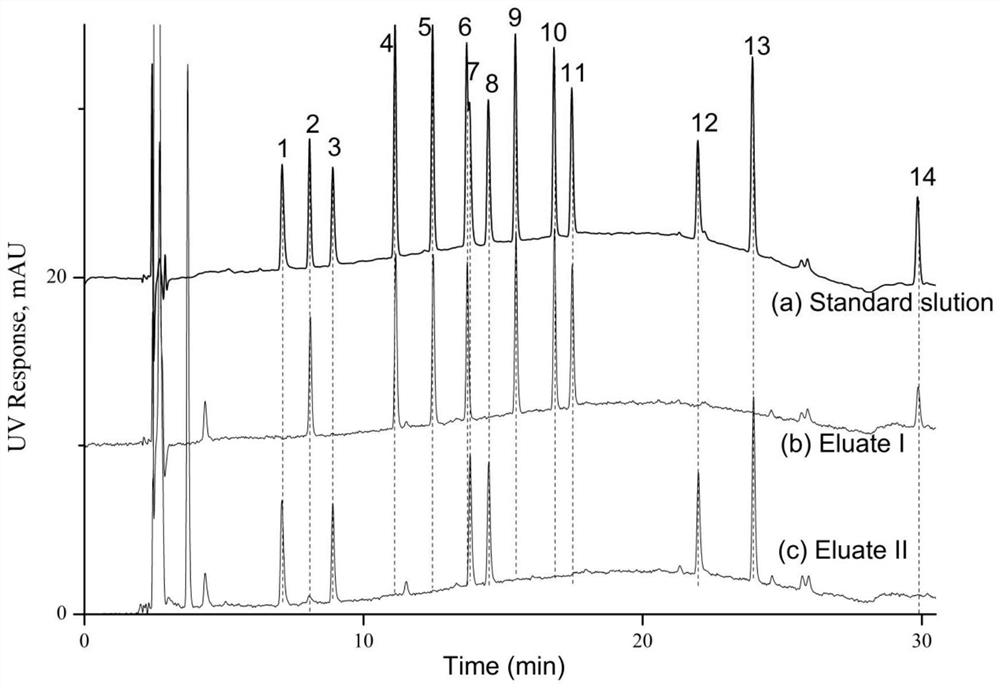

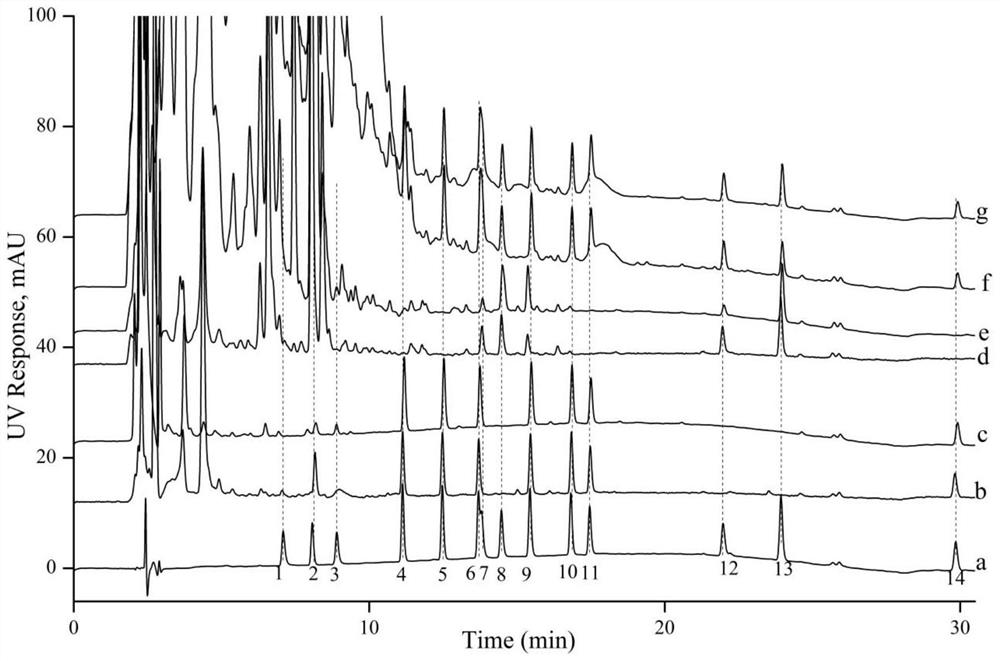

[0032] (5) Disperse 2.0 g of PDEAEMA-B...

Embodiment 2

[0035] 2.0 g of PDEAEMA-BDDE microspheres with epoxy end groups were dispersed in 20 mL of 5% PEI (M w =10000) solution, the solvent was methanol and water (1:1), magnetically stirred, and reacted at 80°C for 1h. After the reaction, filter and wash with deionized water to neutrality, the product obtained is PDEAEMA-PEI with amino end groups 10000,5% ; 2.0 g of PDEAEMA-PEI with amino end groups 10000,5% Disperse in 20mL of methanol, add 5mL of phenyl glycidyl ether, stir with magnetic force, and react at 80°C for 4h. After the reaction, filter and wash with deionized water until neutral, then vacuum dry at 50°C for 24h to obtain PDEAEMA-QPEI 10000,5% MAX adsorbent. Other steps are with embodiment (1).

Embodiment 3

[0037] 2.0 g of PDEAEMA-BDDE microspheres with epoxy end groups were dispersed in 20 mL of 5% PEI (M w =70000) solution, the solvent was methanol and water (1:1), magnetically stirred, and reacted at 80°C for 1h. After the reaction, filter and wash with deionized water to neutrality, the product obtained is PDEAEMA-PEI with amino end groups 70000,5% ; 2.0 g of PDEAEMA-PEI with amino end groups 70000,5% Disperse in 20mL of methanol, add 5mL of phenyl glycidyl ether, stir with magnetic force, and react at 80°C for 4h. After the reaction, filter, wash with deionized water until neutral, and dry in vacuum at 50°C for 24h to obtain PDEAEMA-QPEI 70000,5% MAX adsorbent, other steps are with embodiment (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com