A flooding system suitable for high temperature and high salinity reservoirs

A high-temperature, high-salt, system technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of cumbersome preparation process of functional monomers, poor polymerization activity of functional monomers, and reduced polymer solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Preparation of inorganic components

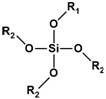

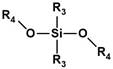

[0054] 100g compound I (R 1 for -CH 2 CH 3 , R 2 for -CH 2 CH 3 ), 35g compound Ⅱ (R 3 for -CH 3 , R 4 for -CH 3 ), 150g compound III (formula III-2, R 8 for H, R 9 , R 10 for -CH 2 CH 3 , m is 2), 10g calcium chloride, 4000g ethanol, 50g deionized water, 5g hydrochloric acid solution (concentration is 1mol / L) join in the three-neck glass bottle that agitator, spherical condenser and thermometer are housed, stir until After all the raw materials are dissolved, the reaction temperature is controlled at 30°C, and the reaction is carried out for 8 hours. The product is centrifuged, washed with ethanol, and then washed with acetone, and the volatile components are removed by vacuum distillation to obtain the inorganic components.

[0055] (2) Preparation of oil displacement system

[0056] Add 1000g of acrylamide, 100g of dimethylacrylamide, 200g of sodium vinylsulfonate, 16g of acryloxypropyltrimethoxysilane, 80g of ...

Embodiment 2

[0059] As described in Example 1, the difference is that the amount of compound II added in step (1) is 45 g.

Embodiment 3

[0061] As described in Example 1, the difference is that the amount of compound II added in step (1) is 25 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com