Gel polymer electrolyte composite membrane and its preparation method and application

A gel polymer and polymer technology, applied in the field of electrochemical energy, can solve the problems of high-rate batteries, limited product pore size change range, and limited application, so as to improve lithium ion conductivity, promote uniform ion deposition, The effect of long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

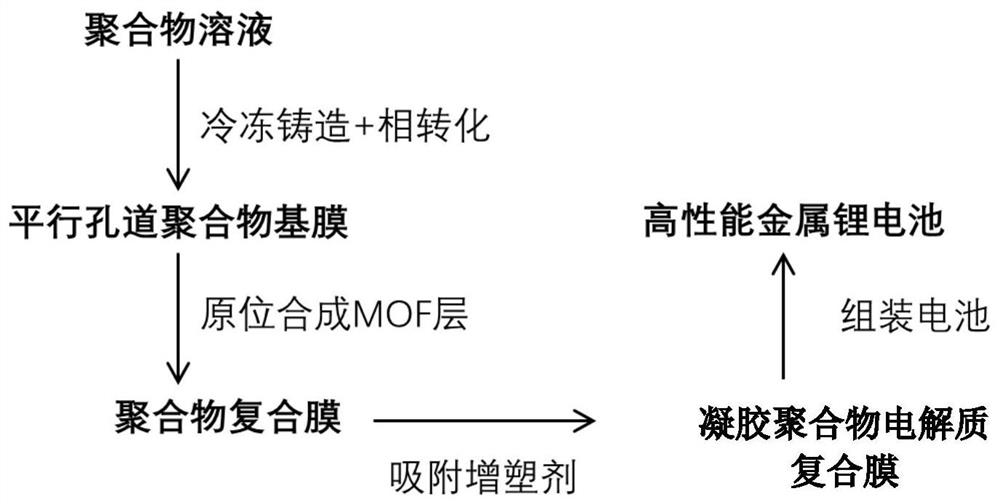

[0038] An aspect of the embodiments of the present invention provides a method for preparing a gel polymer electrolyte composite membrane, which includes:

[0039] Provide polymer base film;

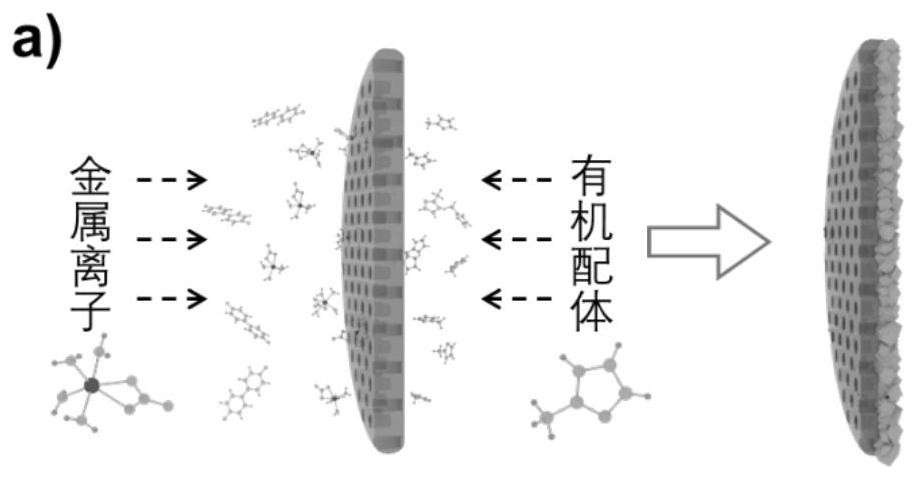

[0040] Forming a metal-organic framework material interface layer (MOF interface layer) on the side of the polymer-based membrane having a dense pore structure by using an interface in-situ polymerization method, thereby obtaining a polymer composite membrane;

[0041] And, the polymer composite membrane is contacted with a plasticizer to gel to form a gel polymer electrolyte composite membrane.

[0042] In some more specific embodiments, the preparation method includes:

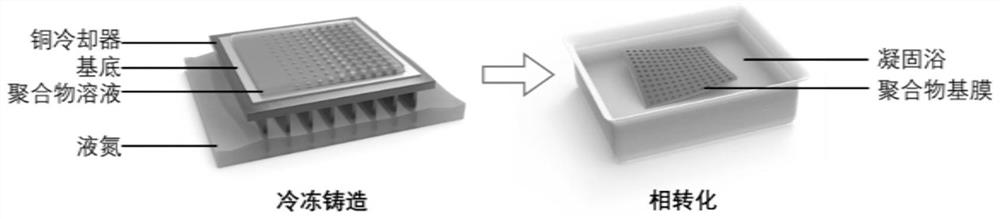

[0043] dissolving the polymer in the first solvent to form a polymer solution, and then coating the polymer solution on the surface of the substrate and placing it on the surface of a cooler for freeze casting treatment for 10-90 seconds, and then immersing the freeze cast treated substrate in Carry out phase inversi...

Embodiment 1

[0102] Add 6g of PVDF-HFP to 34g of DMSO solvent, continue to stir and dissolve to form a uniform solution, pour the solution on a clean and smooth copper plate substrate of 10×10×0.1cm, and use a stainless steel spatula with a gap of 300μm to form a film. The substrate was directly placed on the upper surface of a copper cooler at -196°C for 10s. After the polymer solution was completely frozen and solidified, the substrate was soaked in an absolute ethanol coagulation bath at 15°C for 18 hours. The cured film (about 120 μm) was taken out and washed with absolute ethanol, and placed in a vacuum oven at 60° C. for 6 hours to obtain a PVDF-HFP base film.

Embodiment 2

[0104] Add 2g of PVDF to 8g of DMSO:DMAC=1:1 solvent, continue to stir and dissolve at 60°C to form a homogeneous solution, pour the solution on a clean and smooth glass substrate of 10×10×0.1cm, and use a 200μm gap A stainless steel scraper coats the film. One side of the substrate first contacts the upper surface of the copper cooler soaked in a liquid nitrogen bath (-196° C.), and continues to advance at a certain speed until it is completely in contact with the surface of the copper cooler for 40 seconds. After the polymer solution is completely frozen and solidified, soak the substrate in a pure water coagulation bath at 0°C for 12 hours. The cured film (about 90 μm) was taken out and washed with absolute ethanol, and placed in a vacuum oven at 60°C for 6 hours to obtain a PVDF base film (polymer base film, such as Figure 4b shown). The SEM images of the cross-sectional structure and parallel channel structure of the PVDF base film are as follows: Figure 5a , 5b sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com