Medical tantalum metal bone trabecula material prepared through chemical vapor deposition method and preparation method of medical tantalum metal bone trabecula material

A technology of chemical vapor deposition and metal bone, which is applied in chemical instruments and methods, metal material coating technology, pharmaceutical formulations, etc., can solve problems that are not suitable for large-scale industrial production, difficult to achieve mass production, and high power of laser sintering technology , to achieve the effect of low elastic modulus, high porosity and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing medical tantalum metal trabecular bone material by chemical vapor deposition, which specifically includes the following steps:

[0031] (1) Put medical pure tantalum in the first reaction chamber, put porous carbon substrate in the second reaction chamber, seal the first reaction chamber and the second reaction chamber respectively, and the average pore diameter of the porous carbon substrate is 600-800 μm , the average wire diameter is 100-250 μm, and the average porosity is 81-90%. The first reaction chamber and the second reaction chamber can be any one of quartz reaction chamber or high-purity graphite reaction chamber;

[0032] (2) Vacuumize the first reaction chamber and the second reaction chamber to a certain degree, and then feed argon gas into the first reaction chamber and the second reaction chamber respectively, and the flow rate of the argon gas is 10000-13000ml / min , and ensure that the vacuum degree in the fi...

Embodiment 1

[0041] This embodiment provides a method for preparing medical tantalum metal trabecular bone material by chemical vapor deposition, wherein the first reaction chamber is a quartz reaction chamber, and the second reaction chamber is a high-purity graphite reaction chamber, which specifically includes the following steps:

[0042] (1) Put medical pure tantalum in the first reaction chamber, put porous carbon substrate in the second reaction chamber, the average pore diameter of the porous carbon substrate is 600 μm, the average wire diameter is 100 μm, and the average porosity is 90%. The first reaction chamber and the second reaction chamber are respectively sealed;

[0043] (2) The first reaction chamber and the second reaction chamber are respectively evacuated to a certain degree, and then argon is respectively introduced into the first reaction chamber and the second reaction chamber, and the flow rate of the argon is 10000ml / min, and Ensure that the vacuum degree in the f...

Embodiment 2-9

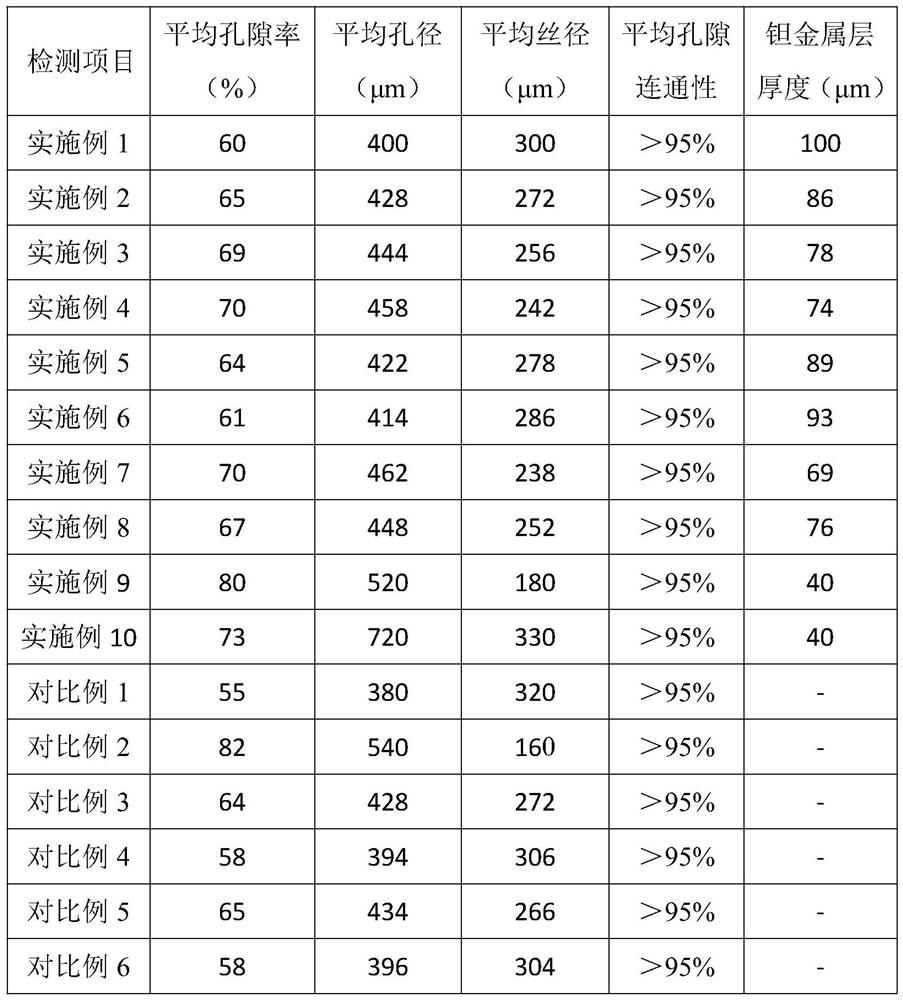

[0049] The difference between embodiment 2-9 and embodiment 1 lies in the difference of various parameters in the process of preparing medical tantalum metal trabecular bone material, the specific difference of each parameter of embodiment 2-9 and embodiment 1 is as follows Table 1 shows.

[0050] Table 1 Example 1-9 Comparison of parameters in the preparation process of tantalum metal trabecular bone materials for traditional Chinese medicine

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average wire diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com