Expandable foaming microsphere capable of being post-crosslinked at high temperature and preparation method thereof

A foamed microsphere, high temperature technology, applied in the preparation of microspheres, microcapsule preparation, application, etc., can solve the problem of non-expansion, high temperature resistance and solvent resistance performance can not be significantly improved, expandable foamed microspheres expand problems such as low magnification, to achieve the effect of simple preparation process, solving high temperature collapse and irregularity and poor solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

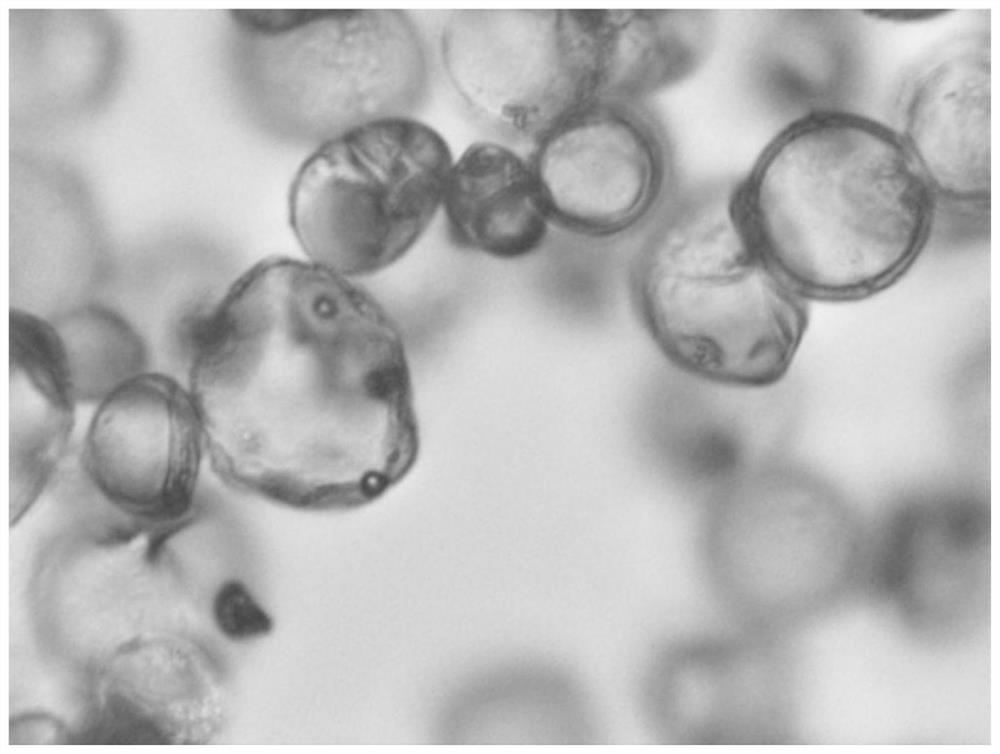

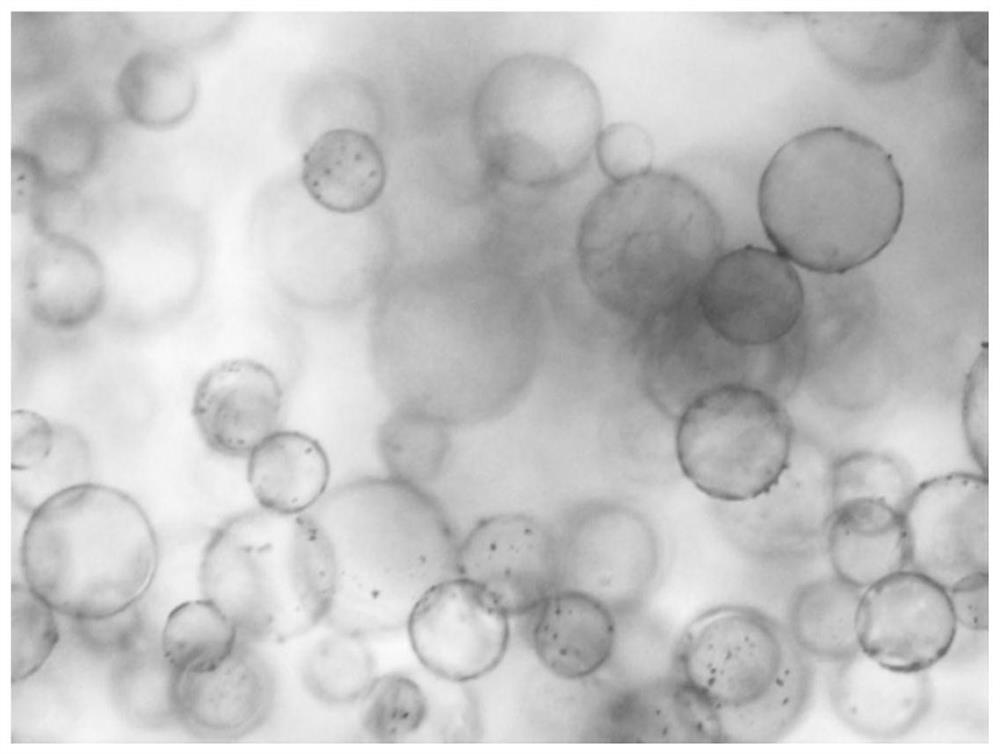

Image

Examples

preparation example Construction

[0067] In a preferred embodiment mode, the preparation method of the high temperature post-crosslinkable expandable foamed microspheres of the present invention comprises the following steps:

[0068] (1) Preparation of the oil phase: 30 parts by weight of isooctane and 30 parts by weight of isopentane, 200 parts by weight of acrylonitrile, 100 parts by weight of methyl methacrylate, 50 parts by weight of methacrylic acid, 60 parts by weight of methyl Hydroxyethyl acrylate, 36 parts by weight of blocked hexamethylene diisocyanate, and 4.7 parts by weight of azobisisobutyronitrile are mixed to obtain an oil phase;

[0069] (2) Preparation of the water phase: 100 parts by weight of magnesium hydroxide sol, 0.2 parts by weight of polyvinylpyrrolidone and 0.15 parts by weight of sodium nitrite are dispersed in 12000 parts by weight of a mass concentration of 16.7% sodium chloride aqueous solution to obtain water Phase, adjust the pH value of the aqueous phase to 3 with hydrochlori...

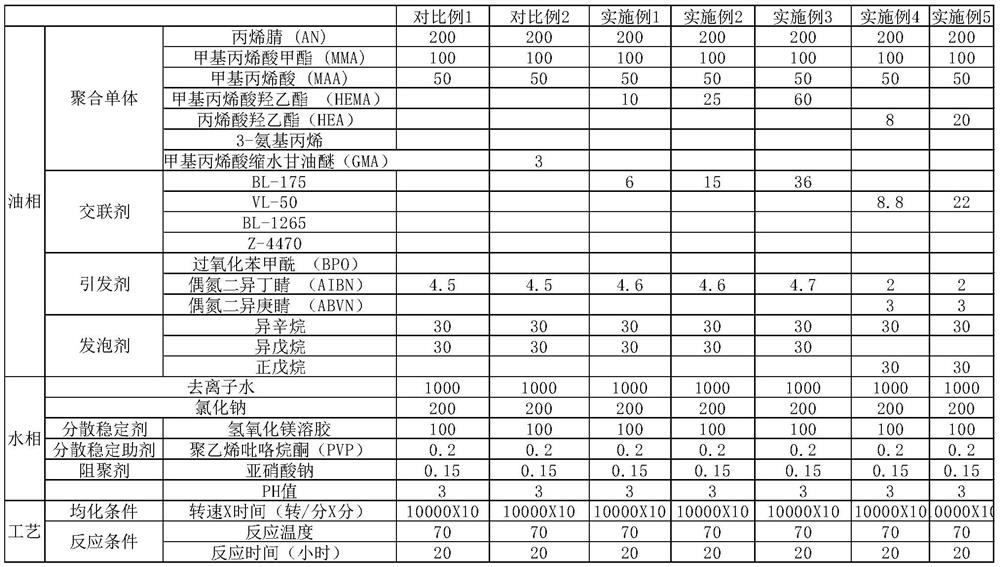

Embodiment 1-12 and comparative example 1-2

[0089] These examples prepare expandable foamed microspheres according to the following method:

[0090] (1) Preparation of oil phase: According to formula table 1 and table 2, mix and stir at 25°C for 10-15 minutes according to the corresponding raw materials and dosage to form a uniform oil phase;

[0091] (2) Preparation of the water phase: Dissolve the corresponding amount of deionized water in which the corresponding sodium chloride is dissolved in the formula table 1 and table 2, then add a corresponding amount of magnesium hydroxide solution, add a corresponding amount of polyvinylpyrrolidone aqueous solution or Sodium lauryl sulfate, then add a corresponding amount of 1% sodium nitrite aqueous solution and stir evenly, then add hydrochloric acid to adjust the pH to 3, and the formed solution is an aqueous phase;

[0092] (3) Homogenization of the water-oil phase: Pour the above-mentioned oil phase into the above-mentioned water phase, and disperse the mixed liquid in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com