Oil controlling makeup cream for improving oily skin and preparation method of oil controlling makeup cream

A cosmetic lotion and skin texture technology, applied in cosmetic preparations, preparations for skin care, cosmetics, etc., can solve the problems of sensitive skin allergic reaction, single function, complex components, etc., to reduce damage and improve oily problems , the effect of excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

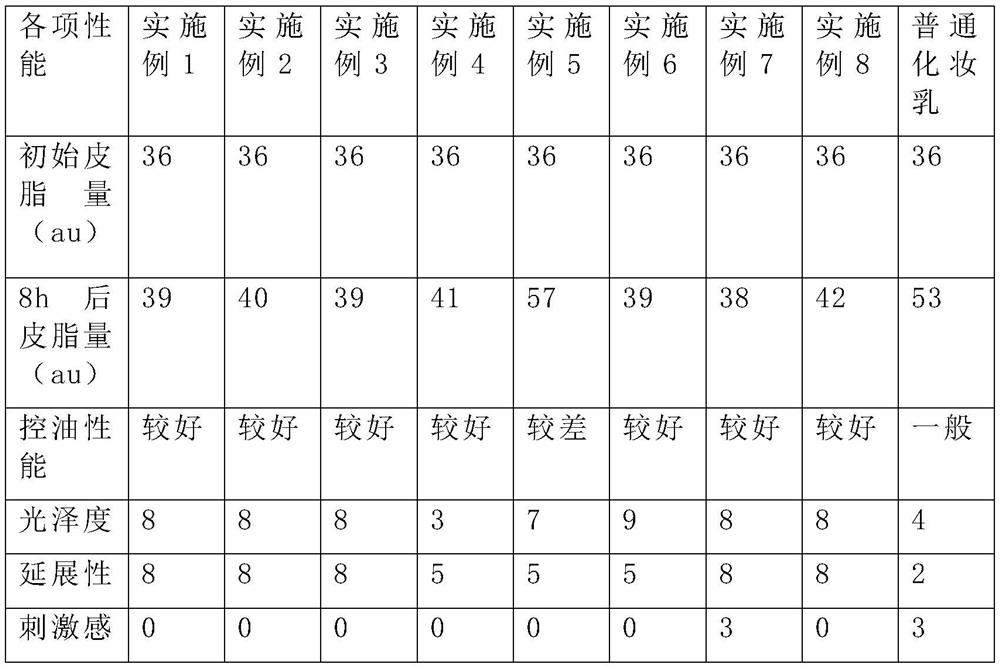

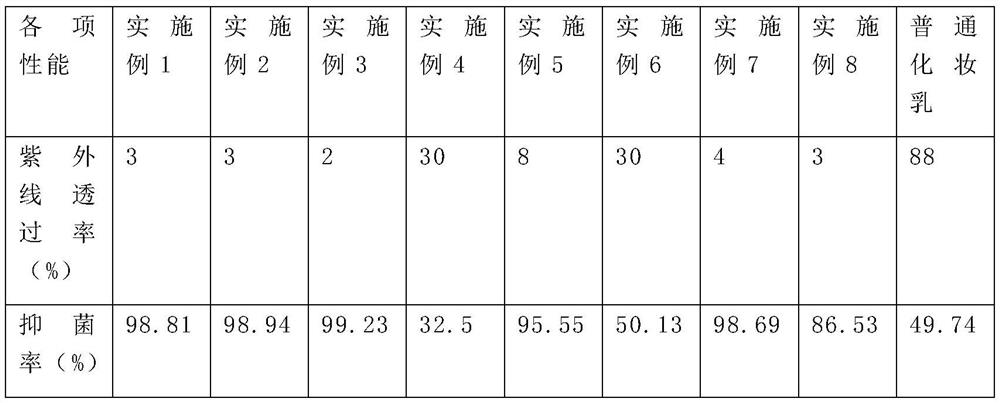

Examples

Embodiment 1

[0048] (1) Raw material preparation: take each component raw material in proportion to obtain the raw material mixture;

[0049] (2) Preparation of modified microspheres:

[0050] A. Preparation of porous microspheres:

[0051] a. Mix polylactic acid, chlorogenic acid, polyhexene oxide, and low-hydrogen silicone oil evenly, add dichloromethane and stir for 5 hours after reacting for 3 minutes, and electrostatically spray into microspheres under 28kV high voltage;

[0052] b. Etching the microspheres in deionized water for 20 hours, and freeze-drying the porous microspheres;

[0053] B. Preparation of the first modified microspheres:

[0054] The obtained porous microspheres were immersed in an ethanol solution to activate for 10 minutes, rinsed with deionized water for 3 times, placed in a silver nitrate solution for 3 hours, then placed in a sodium borohydride solution for 1 minute, taken out, and washed with deionized water for 3 hours. times, freeze-dried to obtain the f...

Embodiment 2

[0066] (1) Raw material preparation: take each component raw material in proportion to obtain the raw material mixture;

[0067] (2) Preparation of modified microspheres:

[0068] A. Preparation of porous microspheres:

[0069] a. Mix polylactic acid, chlorogenic acid, polyethylene oxide, and low-hydrogen silicone oil evenly, add dichloromethane and stir for 6 hours after reacting for 4 minutes, and electrostatically spray into microspheres under 33kV high voltage;

[0070] b. Etching the microspheres in deionized water for 25 hours, and freeze-drying the porous microspheres;

[0071] B. Preparation of the first modified microspheres:

[0072] The obtained porous microspheres were immersed in ethanol solution for activation for 15 minutes, rinsed with deionized water for 3 times, soaked in silver nitrate solution for 5 hours, then placed in sodium borohydride solution for 2 minutes, taken out, and washed with deionized water for 4 minutes. times, freeze-dried to obtain the ...

Embodiment 3

[0084] (1) Raw material preparation: take each component raw material in proportion to obtain the raw material mixture;

[0085] (2) Preparation of modified microspheres:

[0086] A. Preparation of porous microspheres:

[0087] a. Mix polylactic acid, chlorogenic acid, polyethylene oxide, and low-hydrogen silicone oil evenly, add dichloromethane and stir for 7 hours after reacting for 5 minutes, and electrostatically spray into microspheres under 38kV high voltage;

[0088] b. Etching the microspheres in deionized water for 30 hours, and freeze-drying the porous microspheres;

[0089] B. Preparation of the first modified microspheres:

[0090] The obtained porous microspheres were immersed in an ethanol solution for activation for 20 minutes, rinsed with deionized water for 3 times, placed in a silver nitrate solution for 6 hours, then placed in a sodium borohydride solution for 3 minutes, taken out, and washed with deionized water for 5 minutes. times, freeze-dried to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com