Preparation method of topiroxostat

A kind of topicastat, intermediate technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, the preparation method of intermediate 1:

[0038]

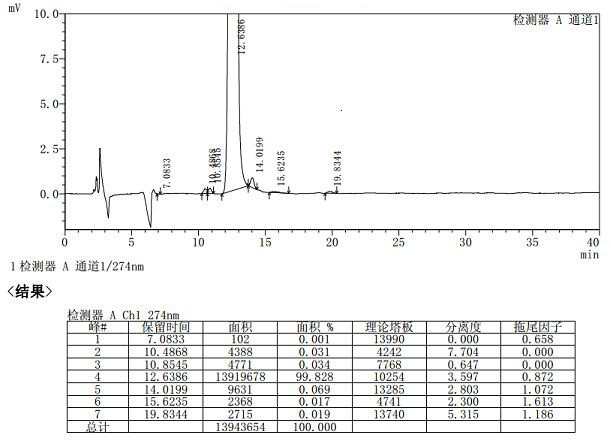

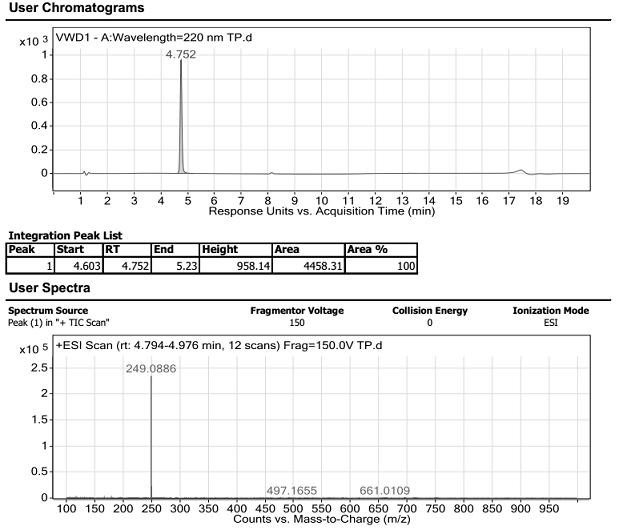

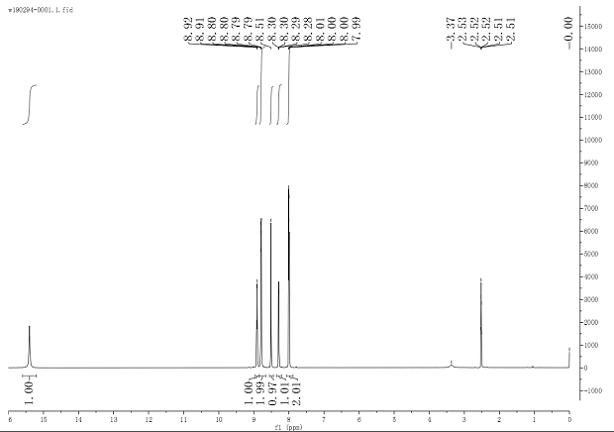

[0039] The starting material (20.0 g, 0.16 mol, 1.0 eq) was dissolved in acetic acid (100 mL) at room temperature (about 25 o C) Add hydrogen peroxide (54.4 g, content 30%, 0.48 mol, 3.0 eq), heat up to 90 o C reacted for 8 h. HPLC showed that there was no raw material left, stop heating, lower to room temperature, add 200 mL of acetone, crystallize for 1 h, filter, and rinse the filter cake twice with a small amount of acetone (100 mL in total). The resulting solid was at 45 o C under blast drying for 10 h. 20.91 g of the product was obtained, yield: 93.9%.

Embodiment 2

[0040] Embodiment 2, the preparation method of intermediate 2:

[0041]

[0042] Intermediate 1 (10.0 g, 71.9 mmol, 1.0 eq) was dissolved in methanol (80 mL), concentrated sulfuric acid (5.0 g) was added dropwise, and the internal temperature was controlled not to exceed 40 o C, heat up to an external temperature of 75 o C, reflux reaction for 8 h. TLC showed that there were not many remaining raw materials, so stop heating, cool down in an ice-water bath, add solid sodium carbonate in batches, and control the internal temperature not to exceed 20 o C, adjust the pH to about 7, filter, and rinse the filter cake twice with a small amount of methanol. methanol at 45 o C and evaporated to dryness under reduced pressure, the obtained solid was dissolved in dichloromethane (100 mL), and washed once with 5% aqueous sodium carbonate solution (15 mL). The dichloromethane phase was separated, dried with a little sodium sulfate, at 45 o C and evaporated to dryness under reduced ...

Embodiment 3

[0043] Embodiment 3, the preparation method of intermediate 3:

[0044]

[0045] Intermediate 2 (12.0 g, 78.4 mmol, 1.0 eq) was added to methanol (80 mL), hydrazine hydrate (80% content, 5.88 g, 94.0 mmol, 1.2 eq) was added, and the temperature was raised to 70 o C, reflux reaction for 6 h. TLC showed that the raw material was completely consumed, and the ice-salt bath was cooled to an internal temperature of 5 o Within C, crystallize for 2 h, filter, and rinse the filter cake with a small amount of methanol (20 mL). The resulting solid was at 45 o C under air blast drying for 4 h to obtain 11.09 g of the product with a yield of 92.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com