A kind of preparation method of platinum-cobalt alloy catalyst

A platinum-cobalt alloy and catalyst technology, which is applied in the field of preparation of platinum-cobalt alloy catalysts, can solve problems such as potential safety hazards and unfavorable development of fuel cell catalysts, and achieve the effects of reducing difficulty, simple post-processing steps, and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

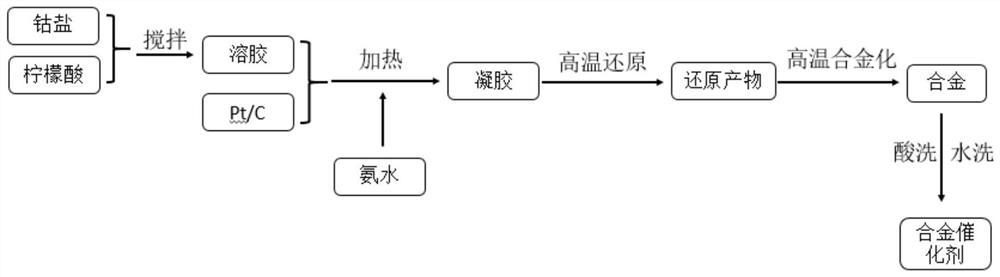

[0035] A preparation method of a platinum-cobalt alloy catalyst, comprising the following steps:

[0036] After mixing 4mL 0.1mol / L cobalt nitrate aqueous solution and 4mL 0.1mol / L citric acid monohydrate aqueous solution, stir until a sol is formed; then add 0.57g platinum-carbon catalyst with a platinum loading of 40% into the above-mentioned sol system, After stirring and ultrasonic dispersion, adjust the pH to 8 with ammonia water; heat in a metal bath at 60°C until a gel is formed; transfer the gel to a tube furnace, keep it warm at 500°C for 1 hour in a nitrogen atmosphere, and cool to room temperature naturally Add a sulfuric acid solution with a concentration of 0.5mol / L to pickle and soak; after pickling, filter with ultrapure water, and finally dry it in a blast drying oven at 50°C to obtain a black powder that is a platinum-cobalt alloy catalyst.

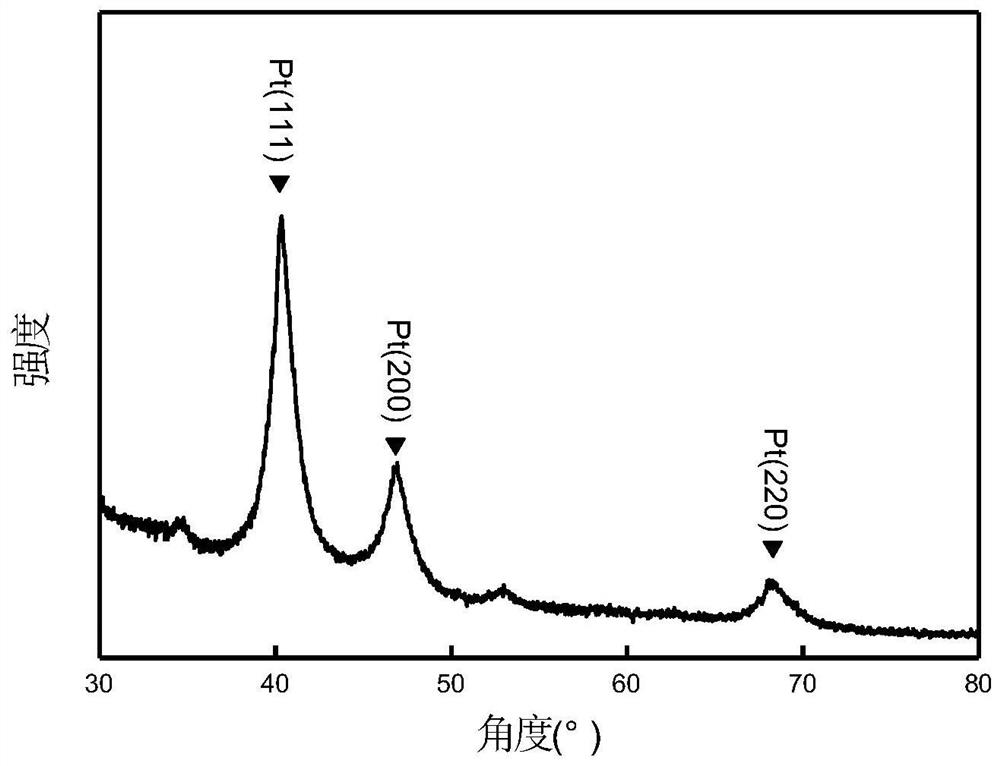

[0037] Carry out X-ray diffraction (X-Ray Diffraction, be called for short XRD) analysis to the platinum-cobalt alloy c...

Embodiment 2

[0039] A preparation method of a platinum-cobalt alloy catalyst, comprising the following steps:

[0040] After mixing 6 mL of 0.1 mol / L cobalt nitrate aqueous solution and 8 mL of 0.1 mol / L citric acid monohydrate aqueous solution, stir until a sol is formed; then add 0.85 g of a platinum-carbon catalyst with a platinum loading of 40% to the above sol system, After stirring and ultrasonic dispersion, adjust the pH to 11 with ammonia water; heat in a metal bath at 90°C until a gel is formed; transfer the gel to a tube furnace, keep it warm at 600°C for 2 hours in a nitrogen atmosphere, and cool to room temperature naturally Add a sulfuric acid solution with a concentration of 0.4mol / L for pickling and soaking; after pickling, filter with ultrapure water, and finally dry it in a blast drying oven at 70°C to obtain a black powder that is a platinum-cobalt alloy catalyst.

Embodiment 3

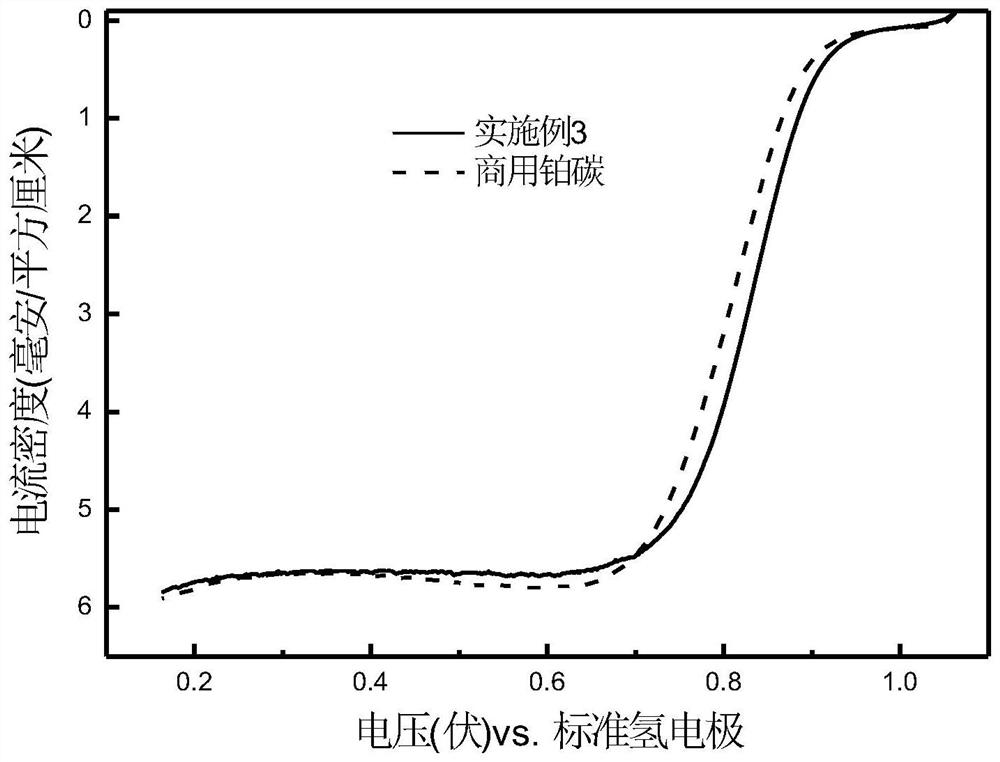

[0042] A preparation method of a platinum-cobalt alloy catalyst, comprising the following steps:

[0043] After mixing 5mL 0.1mol / L cobalt nitrate aqueous solution and 7mL 0.1mol / L citric acid monohydrate aqueous solution, stir until a sol is formed; then add 0.76g platinum-carbon catalyst with a platinum loading of 40% to the above sol system, After stirring and ultrasonic dispersion, adjust the pH to 10 with ammonia water; heat in a metal bath at 150°C to form a gel; transfer the gel to a tube furnace, keep it warm at 400°C for 1.5 hours in a nitrogen atmosphere, and cool naturally to room temperature Add a sulfuric acid solution with a concentration of 0.7mol / L for pickling and soaking; after pickling, filter with ultrapure water, and finally dry it in a blast drying oven at 60°C to obtain a black powder that is a platinum-cobalt alloy catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com