Cerium oxide, zirconium oxide and aluminum oxide composition with enhanced thermal stability

A technology of thermal stability and cerium oxide, which is applied in the field of metals, can solve the problem of low thermal stability of the composition, and achieve the effect of promoting natural precipitation, increasing solubility, and increasing effective activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

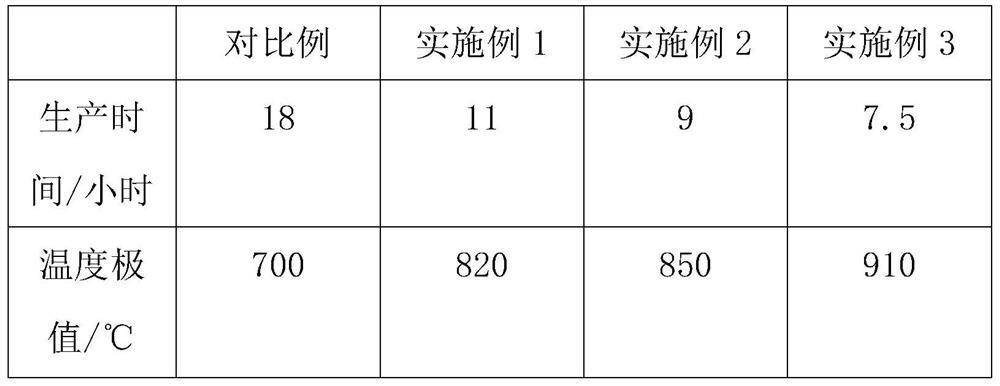

Examples

Embodiment 1

[0034] Step 1: Preparation of basic solution Treatment: Mix 20 parts of zirconium dioxide, 15 parts of cerium oxide, 35 parts of dilanthanum trioxide, 20 parts of neodymium trioxide and 10 parts of aluminum oxide with 10 parts of deionized water respectively , to filter the mixed solution, then fully stir the mixed solution;

[0035] Step 2: Deepening treatment of the metal solution: mix 40 parts of nitric acid, 25 parts of ammonia solution and 40 parts of hydrogen peroxide and add them to the solution respectively, stir the solution fully and then slowly heat it up to 45 degrees Celsius, and the related metals will generate related metal salts Then naturally precipitate in the solution;

[0036] Step 3: Heating and separation treatment: After completely mixing 20 parts of purified water, 20 parts of surfactant, 10 parts of stabilizer and 12 parts of wetting agent in the auxiliary materials, the temperature was raised to 60 degrees Celsius, and then continued Stir for 3 minut...

Embodiment 2

[0041] Step 1: Preparation of basic solution Treatment: Mix 25 parts of zirconium dioxide, 20 parts of cerium oxide, 40 parts of dilanthanum trioxide, 35 parts of neodymium trioxide and 20 parts of aluminum oxide with 35 parts of deionized water respectively , to filter the mixed solution, then fully stir the mixed solution;

[0042] Step 2: Deepening treatment of the metal solution: Mix 55 parts of nitric acid, 30 parts of ammonia solution and 60 parts of hydrogen peroxide and add them to the solution respectively, stir the solution fully and slowly heat it up to 50 degrees Celsius, and the related metals will generate related metal salts Then naturally precipitate in the solution;

[0043] Step 3: Heating and separation treatment: After completely mixing 35 parts of purified water, 25 parts of surfactant, 15 parts of stabilizer and 15 parts of wetting agent in the auxiliary materials, the temperature was raised to 700 degrees Celsius, and then continued Stir for 4 minutes, th...

Embodiment 3

[0048] Step 1: Preparation of basic solution Treatment: Mix 30 parts of zirconium dioxide, 25 parts of cerium oxide, 45 parts of dilanthanum trioxide, 50 parts of neodymium trioxide and 30 parts of aluminum oxide with 60 parts of deionized water respectively , to filter the mixed solution, then fully stir the mixed solution;

[0049] Step 2: Deepening treatment of the metal solution: Mix 70 parts of nitric acid, 35 parts of ammonia solution and 80 parts of hydrogen peroxide and add them to the solution respectively, stir the solution fully and slowly heat it up to 55 degrees Celsius, and the related metals will generate related metal salts Then naturally precipitate in the solution;

[0050] Step 3: Heating and separation treatment: After completely mixing 50 parts of purified water, 30 parts of surfactant, 20 parts of stabilizer and 18 parts of wetting agent in the auxiliary materials, the temperature was raised to 80 degrees Celsius, and then continued Stir for 5 minutes, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com