Resourceful treatment process of industrial high-concentration brine

A treatment process, a technology for concentrated brine, which is applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of smooth sales channels, comprehensive utilization of waste resources, and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

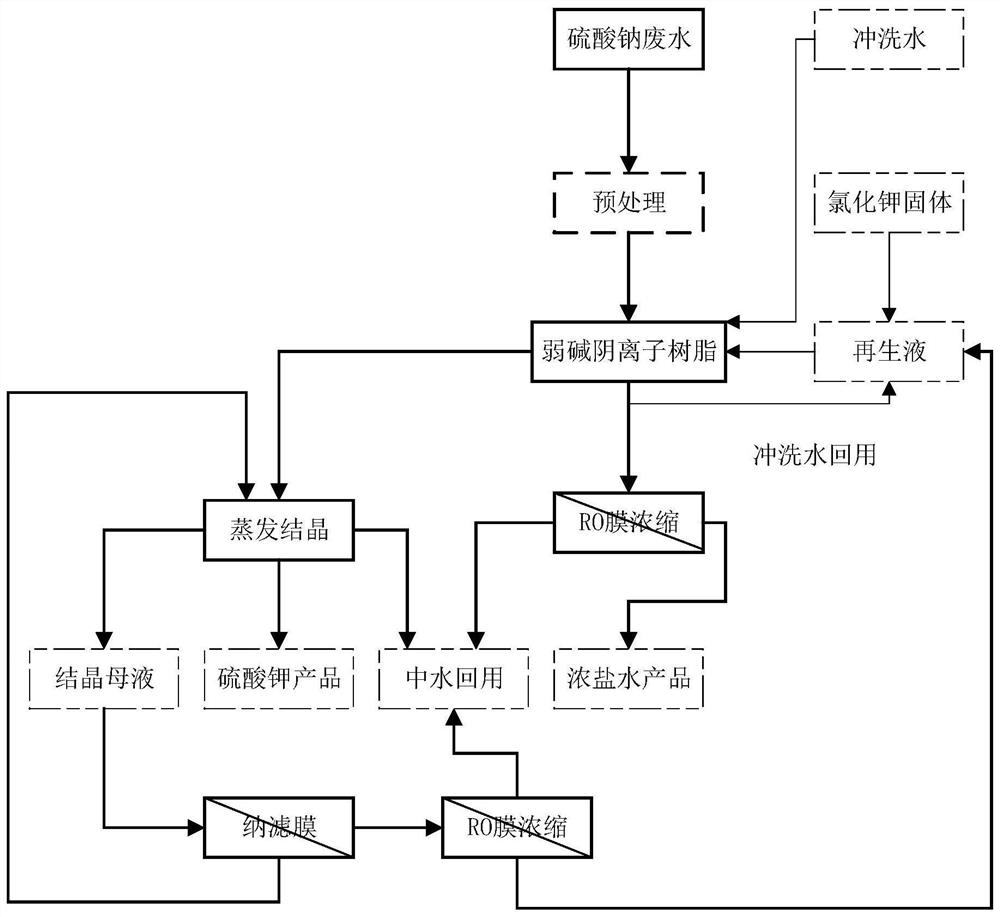

[0042] A resource treatment process for industrial high-concentration brine, such as figure 1 described, including the following steps:

[0043] (1) Sodium sulfate wastewater or wastewater containing sodium sulfate goes through the pretreatment process to remove impurities in the wastewater that affect the operation, use and life of the anion exchange resin, such as suspended solids and fine particles in the wastewater, according to the suspended solids in the wastewater If the concentration of suspended solids in wastewater is lower than 5 mg / L, no pretreatment is required; if the concentration of suspended solids in wastewater is 5-15 mg / L, pretreatment can be selectively carried out; If the concentration of suspended matter in the wastewater is higher than 15mg / L, it needs to be pretreated before entering the ion exchange resin device. Generally used pretreatment methods, according to the concentration of suspended solids in wastewater, choose different technical means or ...

Embodiment approach 2

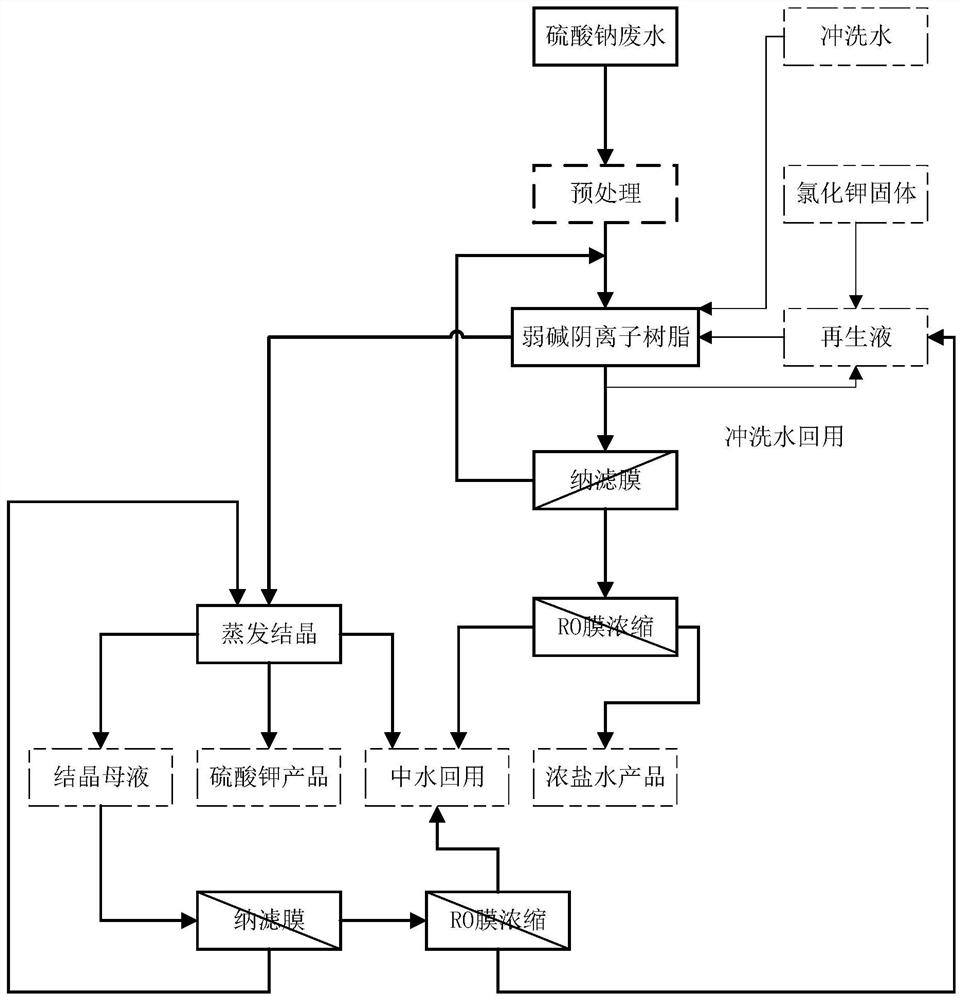

[0054] A resource treatment process for industrial high-concentration brine, such as figure 2 described, including the following steps:

[0055] (1) Sodium sulfate wastewater or wastewater containing sodium sulfate goes through the pretreatment process to remove impurities in the wastewater that affect the operation, use and life of the anion exchange resin, such as suspended solids and fine particles in the wastewater, according to the suspended solids in the wastewater If the concentration of suspended solids in wastewater is lower than 5 mg / L, no pretreatment is required; if the concentration of suspended solids in wastewater is 5-15 mg / L, pretreatment can be selectively carried out; If the concentration of suspended matter in the wastewater is higher than 15mg / L, it needs to be pretreated before entering the ion exchange resin device. Generally used pretreatment methods, according to the concentration of suspended solids in wastewater, choose different technical means or...

Embodiment 1

[0066] refer to figure 1 , In this embodiment, anion exchange resin, RO membrane and evaporative crystallizer are used to carry out resourceful comprehensive treatment of sodium sulfate-containing wastewater, and respectively realize potassium sulfate solid recovery, concentrated brine recovery and reclaimed water recovery.

[0067] Sodium sulfate containing wastewater water volume 100m 3 / h, the wastewater COD4 2- Content 4980mg / L, Cl - The content is 460mg / L, and the cation is mainly Na + , the wastewater contains a small amount of other ions, K + Content 24.5mg / L, Ca 2+ Content 348mg / L, Mg 2+ The content is 12.8mg / L, the total alkalinity content is 77mg / L, and other trace ions, such as fluoride, manganese, copper, iron, aluminum, silicon, etc., are industrial high-concentration brine with relatively complex components. The concentration of suspended solids in wastewater is less than 15mg / L, and there are no particulate impurities visible to the naked eye, so no pretre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com