Fatty acid methyl ester sodium sulfonate composition particle for use in production of detergents

A technology of sodium fatty acid methyl ester sulfonate and composition, which is applied in detergent compositions, surface active detergent compositions, organic detergent compositions, etc., and can solve poor solubility at low temperature, doubts about solubility in water, and increase the combination of MES Difficulty and cost of granulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

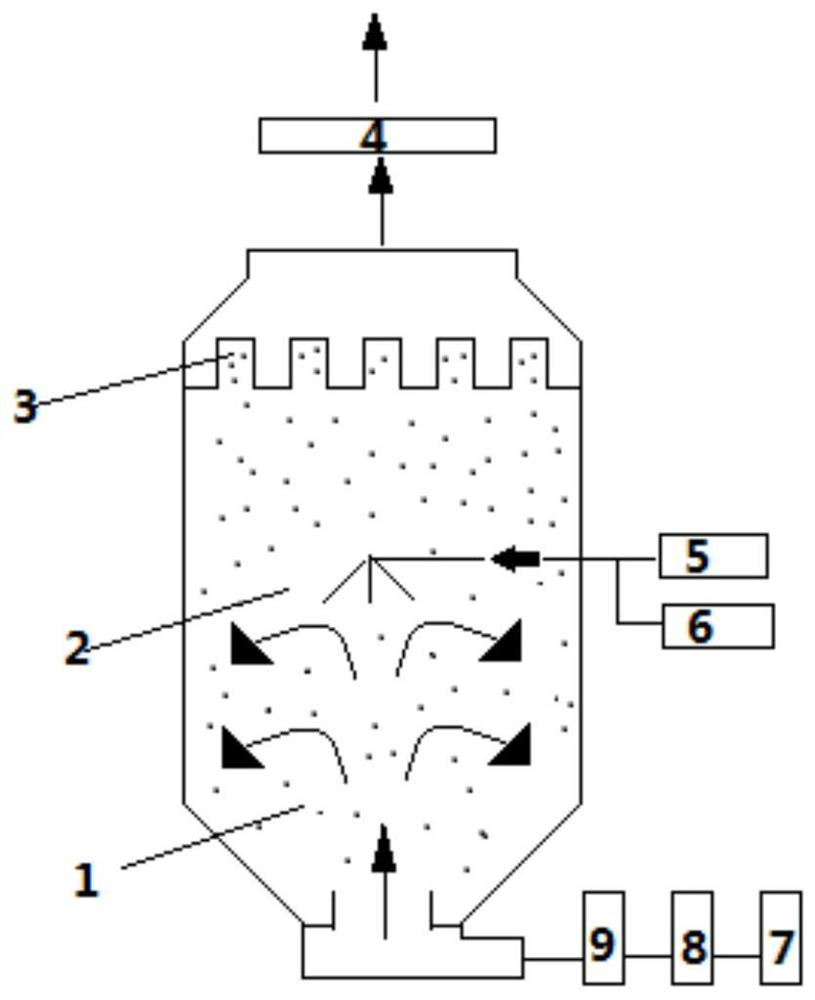

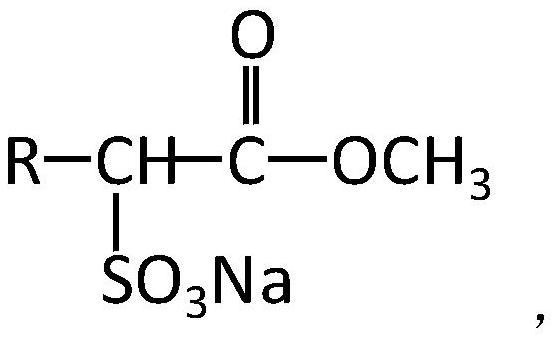

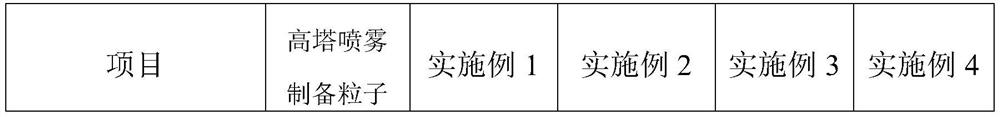

Embodiment 1

[0103] 30 parts by mass of MES, 30 parts by mass of soda ash, 2 parts by mass of sodium carboxymethyl cellulose, and 38 parts by mass of sodium sulfate are crushed and sieved into a fine powder with a particle size of ≤0.20mm, and put into a closed In the fluidized bed, air is introduced from the bottom of the fluidized bed, fluidized by air and mixed with powder to obtain a solid mixture; 0.5 parts by mass of acrylic acid homopolymer and 0.1 parts by mass of natron are dissolved in 25 parts by mass of In the binder, it is prepared as a liquid containing polymer, saponine and binder, and the liquid containing polymer, saponine and binder is sprayed and atomized from top to bottom in the fluidized bed, and the fluidized state The solid mixture is fully contacted for fluidized bed granulation. After the granulation is completed, it is dried in the fluidized bed and passed through a 150-mesh sieve. The particles on the sieve are the final MES composition particles. The solid mixtu...

Embodiment 2

[0106] 40 parts by mass of MES, 15 parts by mass of soda ash, 0.5 parts by mass of sodium carboxymethyl cellulose, and 44.5 parts by mass of sodium sulfate are crushed and sieved into fine powder with a particle size of ≤0.20mm, and put into a closed In the fluidized bed, enter air from the bottom of the fluidized bed, rely on air fluidization and carry out powder mixing to obtain a solid mixture; dissolve 1 mass part of maleic acid-acrylic acid copolymer and 0.5 mass part of natron in 40 parts by weight of the binder are prepared into a liquid containing polymer, sodium natron and binder, and spray the atomized liquid containing polymer, sodium sodium and binder from top to bottom in the fluidized bed, and flow The solid mixture in the liquidized state is fully contacted for fluidized bed granulation. After the granulation is completed, it is dried in the fluidized bed and passed through a 150-mesh sieve. The particles on the sieve are the final MES composition particles, and ...

Embodiment 3

[0109] 50 parts by mass of MES, 21 parts by mass of soda ash, 0.5 parts by mass of sodium carboxymethylcellulose, and 28.5 parts by mass of sodium sulfate are crushed and sieved into fine powders with a particle size of ≤0.15 mm, and put into a closed In the fluidized bed, enter air from the bottom of the fluidized bed, rely on air fluidization and powder mixing to obtain a solid mixture; 5 parts by mass of acrylic acid-styrene copolymer, 5 parts by mass of natron are dissolved in 60 In the binder of mass parts, it is prepared as a liquid containing polymer, sodium bicarbonate and binder, and the liquid containing polymer, sodium bicarbonate and binder is sprayed and atomized from top to bottom in the fluidized bed, and fluidized The solid mixture in the state is fully contacted for fluidized bed granulation. After the granulation is completed, it is dried in the fluidized bed and passed through a 150-mesh sieve. The particles on the sieve are the final MES composition particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com