A kind of ready-mixed concrete mixed with steel slag and preparation method thereof

A technology of ready-mixed concrete and steel slag, applied in the field of building materials, can solve the problems of affecting the ecological environment, consuming large fossil energy, aggravating the greenhouse effect, etc., and achieving the effect of improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

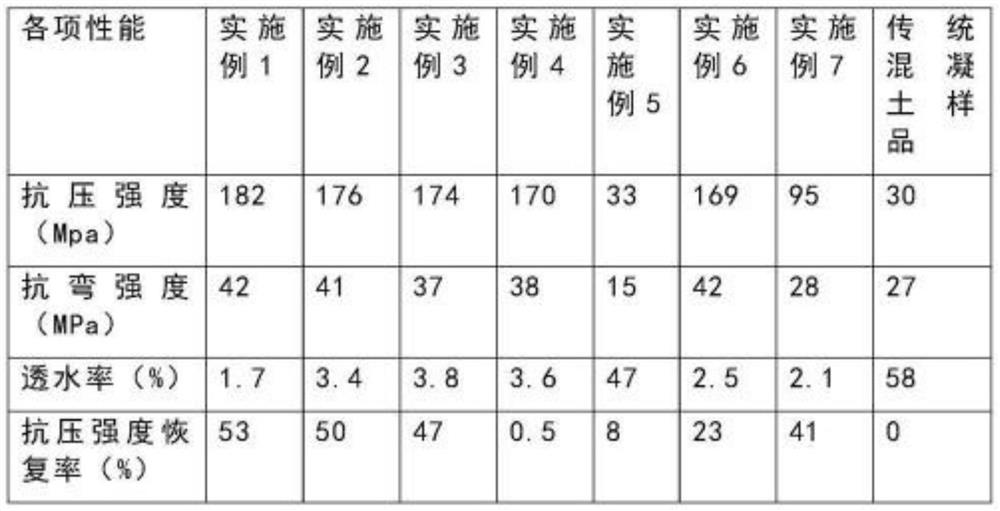

Examples

Embodiment 1

[0046] Preparation S1 microbial broth: peptone, beef extract, urea, yeast extract blend microbial nutrient solution, the nutrient solution was poured into a microorganism Bacillus subtilis bacteria culture well stirred 1min, to obtain microbial broth;

[0047] Preparation of modified fibers S2:

[0048] A. Preparation of porous fiber: polyvinyl alcohol in distilled water was added and heated to 85 ℃, at 300r / min speed stirring 0.5h, cooled to 55 ℃, hydrochloric acid was added until a pH of 1, citral added, the crosslinking reaction 1.5h, continue to heat up to 85 ℃, adding nano particles of silicon nitride, calcium carbonate, hydrochloric acid, rubber powder and slag, at 800r / min speed stirring 25min, made porous fibers by electrospinning;

[0049] B. Modification of porous fibers: the fibers soaked in the porous silane coupling agent 4h, dry out after soaking placed microbial broth IH, placed under 35 ℃ IH removed after drying, was repeated eight times, modified fiber prepare...

Embodiment 2

[0060] Preparation S1 microbial broth: peptone, beef extract, urea, yeast extract blend microbial nutrient solution, the nutrient solution was poured into a microorganism Bacillus subtilis bacteria culture well stirred 1.5min, to obtain microbial broth;

[0061] Preparation of modified fibers S2;

[0062] A. Preparation of porous fiber: polyvinyl alcohol in distilled water is added and heated to 90 ℃, at 300r / min stirring speed IH, cooled to 60 ℃, hydrochloric acid was added until pH 2, citral added, the crosslinking reaction 2h , continue to heat up to 90 ℃, adding nano particles of silicon nitride, calcium carbonate, hydrochloric acid, rubber powder and slag, at 800r / min speed stirring 35min, made porous fibers by electrospinning;

[0063] B. Modification of porous fibers: the fibers soaked in the porous silane coupling agent 5h, dry out after the microbial cell suspension was placed in soaking 1.5h, 1.5h after removing oven dried under conditions of 37 ℃, repeat 9 times to ...

Embodiment 3

[0074] Preparation S1 microbial broth: peptone, beef extract, urea, yeast extract blend microbial nutrient solution, the nutrient solution was poured into a microorganism Bacillus subtilis bacteria culture well stirred 2min, to obtain microbial broth;

[0075] Preparation of modified fibers S2;

[0076] A. Preparation of porous fiber: polyvinyl alcohol in distilled water is added and heated to 95 deg.] C, at 300r / min speed stirring 1.5h, cooled to 65 ℃, hydrochloric acid was added until pH 3, citral added, the crosslinking reaction 2.5h, continue to heat to 95 deg.] C, adding nano particles of silicon nitride, calcium carbonate, hydrochloric acid, rubber powder and slag, at 800r / min speed was stirred for 45 min, made porous fibers by electrospinning;

[0077] B. Modification of porous fibers: the fibers soaked in the porous silane coupling agent 6h, dry out after the microbial cell suspension was placed in soaking 2h, placed under 40 ℃ removed after drying 2h, repeated 10 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com