Preparation method of perovskite light-emitting diode (PeLED) with adjustable blue-green light chromaticity

A technology of light-emitting diodes and perovskites, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as difficulties and few researches on blue light bands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The two-dimensional organic-inorganic hybrid perovskite material is synthesized according to the following steps:

[0031] Step 1. The purity of all purchased chemical reagents is analytical grade. Add 3 mL of phenethylamine (PEA) solution into a round bottom flask equipped with magnets, and slowly drop 3 mL of hydrobromic acid (HBr) to form a white emulsion. Fill the round-bottom flask with argon, and fix the round-bottom flask on a magnetic stirrer with ice bath and stir for 2h. Remove the flask, add absolute ethanol dropwise until it is completely dissolved, and then transfer to the rotary evaporator to evaporate the excess solvent. The product obtained by rotary evaporation was put into a Buchner funnel, washed with ether and filtered under reduced pressure to obtain a pure white solid. Place it in a vacuum drying oven at 80°C for 12 hours to obtain pure bromophenethylamine (PEABr).

[0032] Step 2. Weigh 0.800g (2mmol) PEABr and 0.734g (2mmol) PbBr 2 , 0.022xg (0.2x ...

Embodiment 2

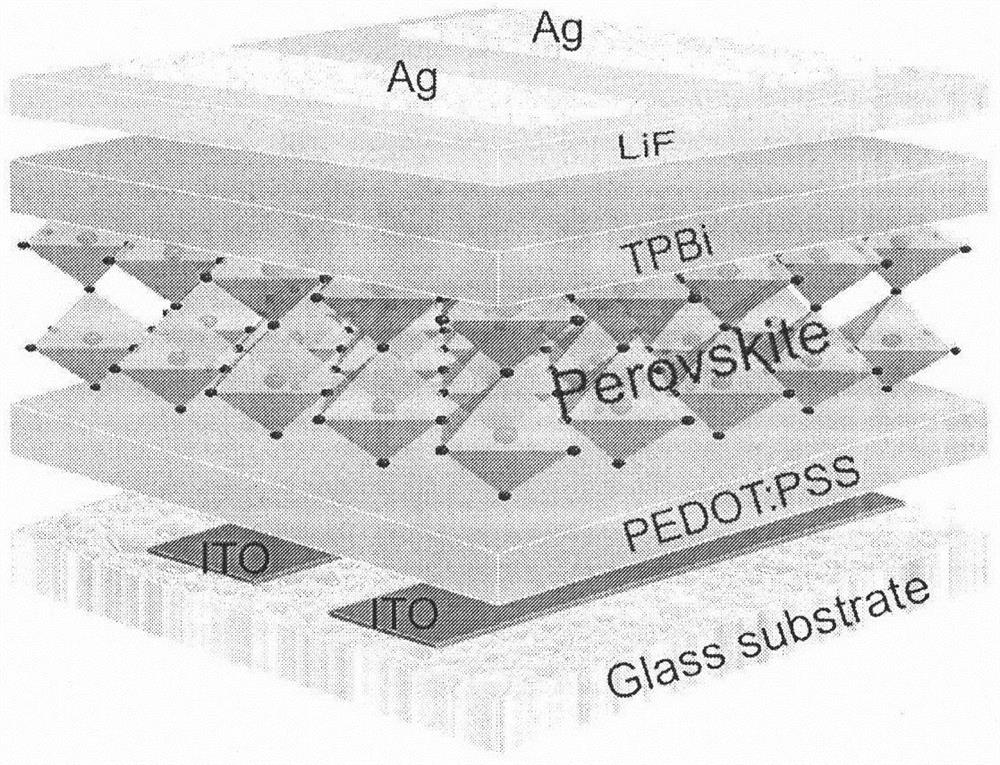

[0034] Such as figure 1 As shown, the structure of the light-emitting device from bottom to top is: ITO glass substrate, PEDOT: PSS, perovskite light-emitting layer, TPBi, LiF and Ag.

[0035] In the first step, the conductive indium tin oxide on the surface of the ITO glass substrate is patterned; acetone, isopropanol, and ultrapure water are used for ultrasonic for 15 minutes, and then the ITO is rinsed with ultrapure water several times to ensure a clean surface.

[0036] In the second step, the cleaned ITO glass substrate is placed in an infrared drying box and dried for 20 minutes.

[0037] In the third step, the dried ITO glass substrate is subjected to 15min ultraviolet ozone treatment, the purpose is to improve the ITO surface adhesion and work function.

[0038] In the fourth step, the surface of the ITO glass substrate completed by ultraviolet ozone was spin-coated with PEDOT:PSS at 5000r / min and 40s, and annealed at 120°C for 10min.

[0039] In the fifth step, the spin-coated...

Embodiment 3

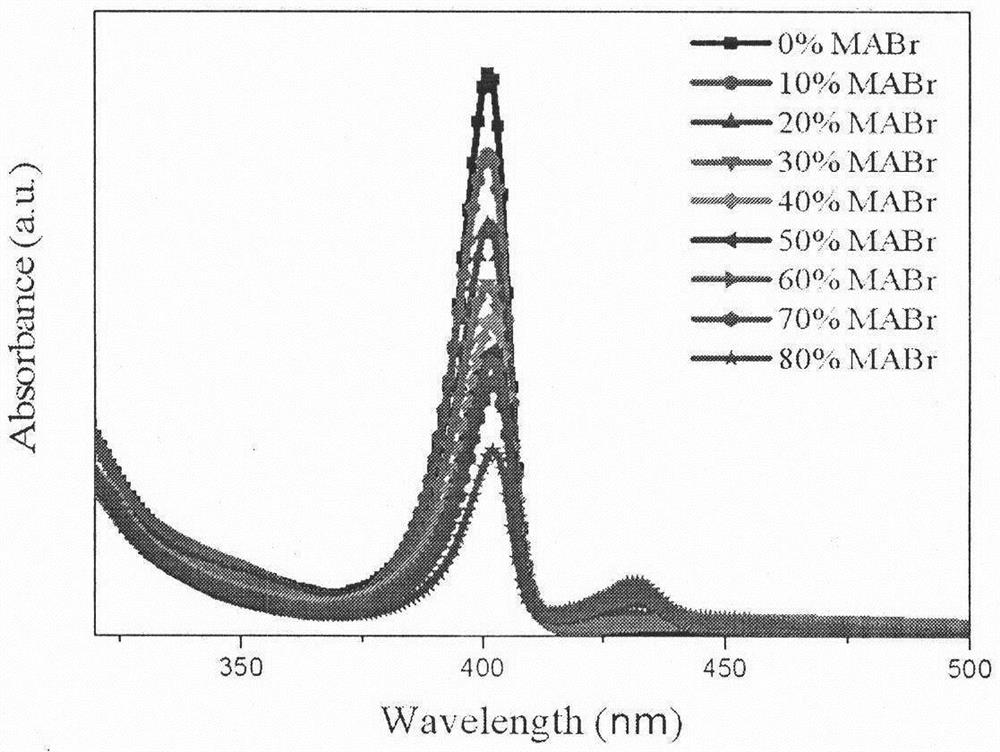

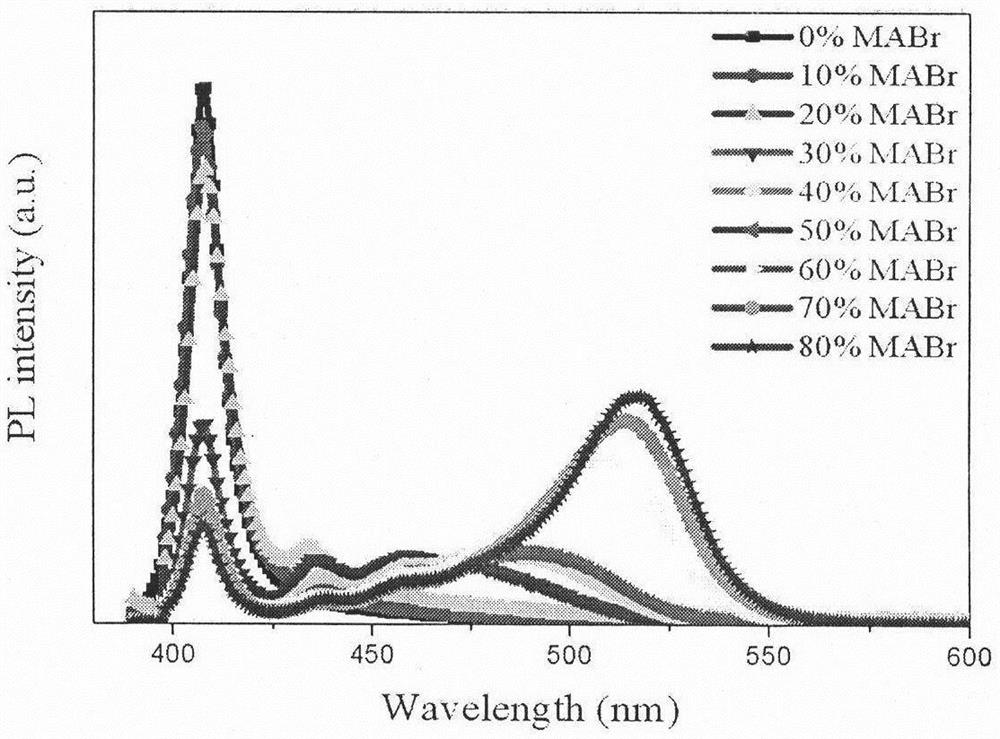

[0043] Ultraviolet-visible spectroscopy (U-V) absorption test was performed on the perovskite film spin-coated on the quartz glass substrate.

[0044] figure 2 As shown, the two absorption peaks of this type of perovskite film are located at 400 nm and 430 nm, respectively.

[0045] The absorption peak at 400nm corresponds to PEA 2 PbBr 4 The intrinsic absorption of the material, its intensity gradually decreases with the increase of the MABr doping ratio, and the absorption peak intensity at 430nm increases with the increase of the MABr doping, which shows that in (PEA) 2 (MA) n-1 PbnBr 3n+1 The structure phase with n>1 is produced in the

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com