High-temperature electrothermal coating and preparation method thereof

A technology for electrothermal coatings and high temperature resistant fillers, applied in conductive coatings, fire retardant coatings, alkali metal silicate coatings, etc., can solve the problems of low surface heating temperature, affecting the heating effect of coatings, and restricting the development of electrothermal coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

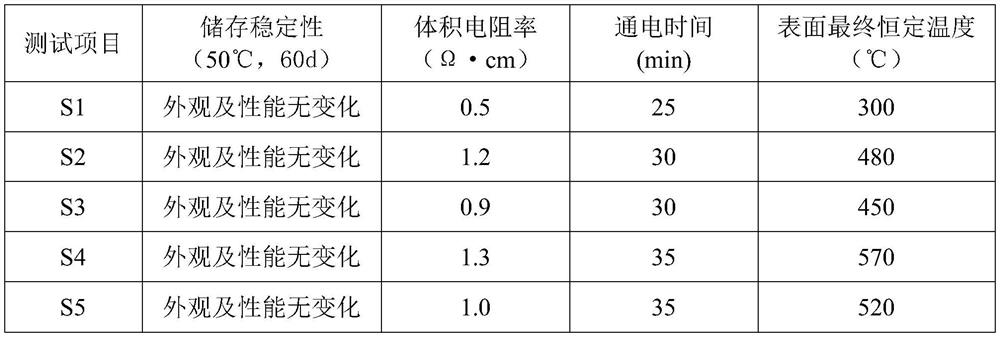

Examples

Embodiment 1

[0031] A method for preparing high-temperature electric heating paint, characterized in that it comprises the following steps:

[0032] S1) In container A, add water, dispersant sodium dodecylbenzene sulfonate 3% successively, stir well and then add the first electrothermal filler 30% (carbon nanotube 25%+ conductive carbon black 5%) and resistant High-temperature filler silicon carbide 3%, dispersed until the system is uniform, to obtain a slurry;

[0033] S2) In container B, add water, high temperature resistant adhesive water glass 20% in sequence, and after stirring evenly, add functional auxiliary wetting agent dioctyl sodium sulfosuccinate 1%, defoamer polyether modified silicon 1%, dispersed until the system is uniform, to obtain the base material;

[0034] S3) The second electrothermal filler silver powder is prepared after anti-oxidation treatment; the slurry is added to the base material under the condition of stirring, dispersed until the system is uniform, and the...

Embodiment 2

[0037] A method for preparing high-temperature electric heating paint, characterized in that it comprises the following steps:

[0038] S1) In container A, add water, dispersant polyethylene glycol 2% in sequence, stir evenly, then add the first electrothermal filler graphene 35% and high temperature resistant filler mica powder 5%, disperse until the system is uniform, and obtain a slurry ;

[0039] S2) In container B, add water, high temperature resistant adhesive silicate 5% in sequence, and after stirring evenly, add functional additives defoamer polydimethylsiloxane 1%, ABS / PC flame retardant 2% , dispersed until the system is uniform, to obtain the base material;

[0040] S3) The second electrothermal filler aluminum powder is prepared after anti-oxidation treatment; the slurry is added to the base material under stirring, dispersed until the system is uniform, and then 1% of the second electrothermal filler aluminum powder is added, and dispersed again until the system i...

Embodiment 3

[0043] A method for preparing high-temperature electric heating paint, characterized in that it comprises the following steps:

[0044] S1) In container A, add water, dispersant polyvinylpyrrolidone 5% in turn, stir well and then add the first electric heating filler 25% (carbon fiber 22% + natural graphite 3%) and high temperature resistant filler quartz powder 8%, disperse Until the system is uniform, the slurry is obtained;

[0045] S2) In container B, add water, high temperature resistant adhesive phosphate 25% in sequence, and after stirring evenly, add functional auxiliary wetting agent acetylenic glycol ethoxylate 1%, silicon defoamer 1%, PBT / PET flame retardant 1%, dispersed until the system is uniform, to obtain the base material;

[0046] S3) The second electrothermal filler copper powder is prepared after anti-oxidation treatment; the slurry is added to the base material under the condition of stirring, dispersed until the system is uniform, and then 5% of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com