MgGa2O4 ultraviolet detector and preparation method thereof

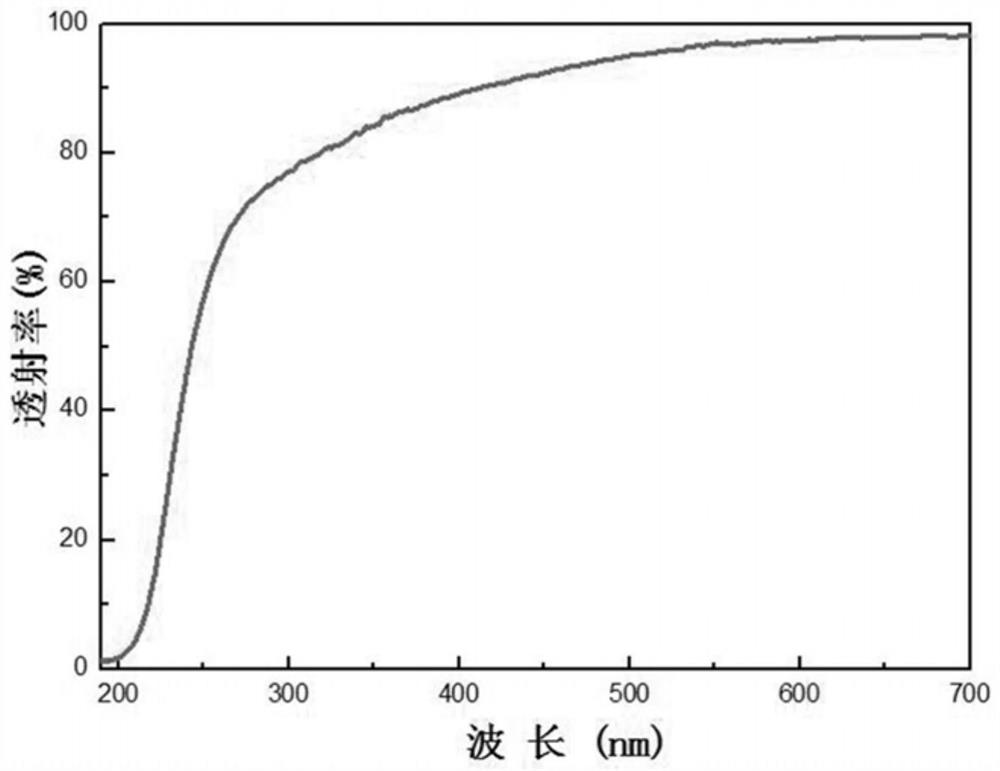

A technology of ultraviolet detectors and thin films, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, and final products. It can solve the problems of large dark current of ultraviolet detectors, steep absorption cut-off edge of crystal quality, and low dark current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

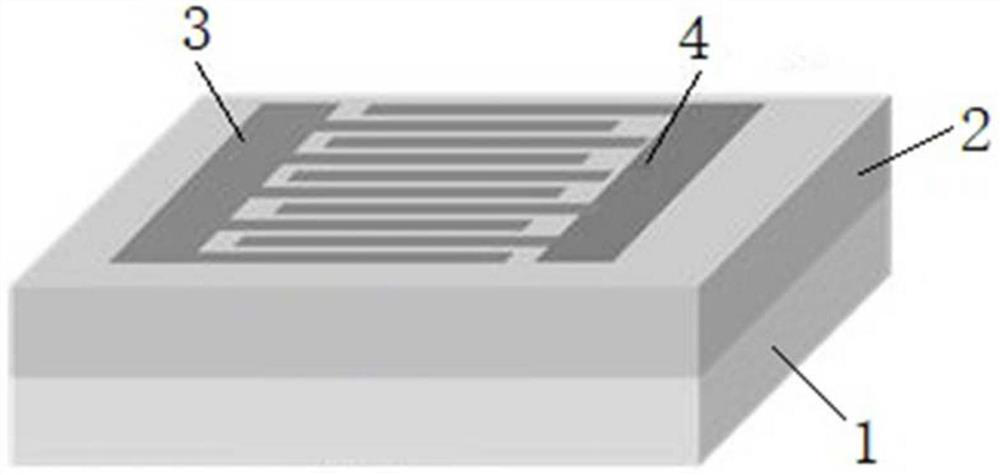

[0047] MgGa 2 o 4 The preparation method of thin film 2 is: using metal organic compound chemical vapor deposition (MOCVD) equipment, using organic magnesium compound as magnesium source, organic gallium compound as gallium source, heating the substrate to a certain temperature in an atmosphere of excess oxygen, and depositing MgGa 2 o 4 film.

[0048] The preparation method of interdigital electrode 3 is: in MgGa 2 o 4 Negative photolithography is used on the film to form an interdigital electrode mask, and a small coating machine is used to sputter metal on the interdigital electrode mask, and then the interdigital electrode mask is removed by ultrasonic methods to form interdigital electrodes.

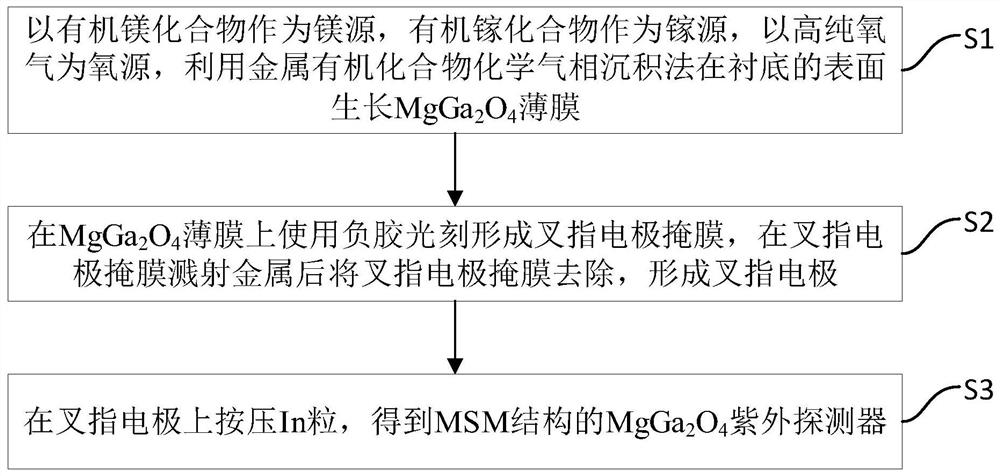

[0049] The foregoing has specified the MgGa provided by the present invention 2 o 4 The structure of the UV detector. with the above MgGa 2 o 4 Corresponding to the ultraviolet detector, the present invention also provides a kind of MgGa 2 o 4 Preparation method of ultra...

Embodiment 1

[0071] Put the cleaned sapphire substrate into the growth chamber of the MOCVD equipment, adjust the growth temperature to 800°C, and the pressure to 4000Pa. Use dimethylmagnesocene as the magnesium source, trimethylgallium as the gallium source, the carrier gas flow rate of the magnesium source is 5 sccm, the carrier gas flow rate of the gallium source is 10 sccm, and the flow rate of high-purity oxygen gas is 500 sccm, which is much larger than the magnesium source and The flow rate of the gallium source, grow for 1h, turn off the organic source and oxygen, and reduce the substrate temperature to room temperature at 0.6°C / s to obtain MgGa 2 o 4 film.

[0072] MgGa 2 o 4 The film is moved into the annealing furnace, using an oxygen atmosphere, the oxygen flow rate is 12 sccm, and the temperature of the annealing furnace is raised to 800°C at a heating rate of 0.4°C / s. After 10min, the MgGa is taken out from the annealing furnace 2 o 4 film.

[0073] in MgGa 2 o 4 On t...

Embodiment 2

[0078] Put the cleaned sapphire substrate into the growth chamber of the MOCVD equipment, adjust the growth temperature to 700°C, and the pressure to 3000Pa. Use diethylmagnesocene as the magnesium source, triethylgallium as the gallium source, the carrier gas flow rate of the magnesium source is 20sccm, the carrier gas flow rate of the gallium source is 40sccm, and the flow rate of high-purity oxygen is 800sccm, which is much larger than the magnesium source and The flow rate of the gallium source, grow for 1.3h, turn off the organic source and oxygen, and lower the substrate temperature to room temperature at 0.5°C / s to obtain MgGa 2 o 4 film.

[0079] MgGa 2 o 4 Move the film into the annealing furnace, use an oxygen atmosphere, and the oxygen flow rate is 8sccm, raise the temperature of the annealing furnace to 600°C at a heating rate of 0.2°C / s, keep the temperature for 5min, and then remove the MgGa from the annealing furnace 2 o 4 film.

[0080] in MgGa 2 o 4 On...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dark current | aaaaa | aaaaa |

| Dark current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com