Microalgal oil microcapsule and preparation method thereof

A technology of microcapsules and algae oil, which is applied in the direction of microcapsule preparation, preparation of microspheres, preservation of fatty substances by additives, etc. It can solve the problems of increasing the difficulty and time of stirring and dissolving, and low oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

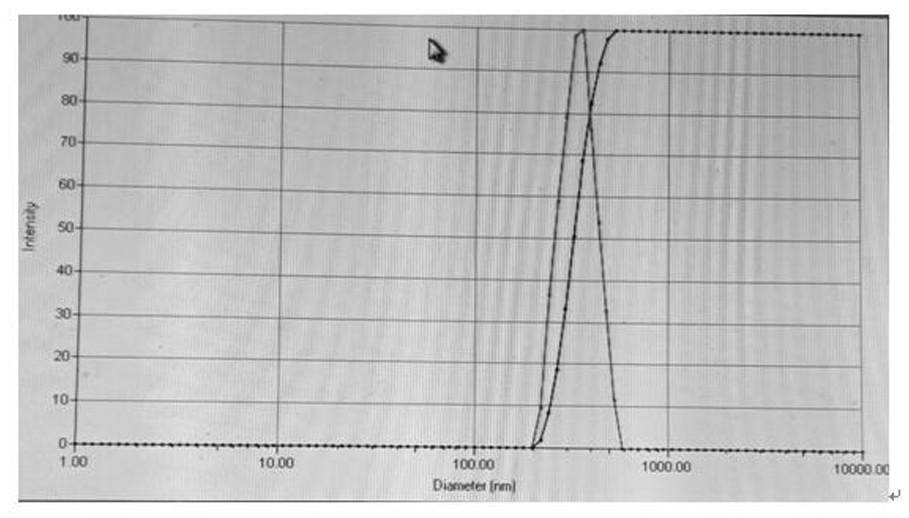

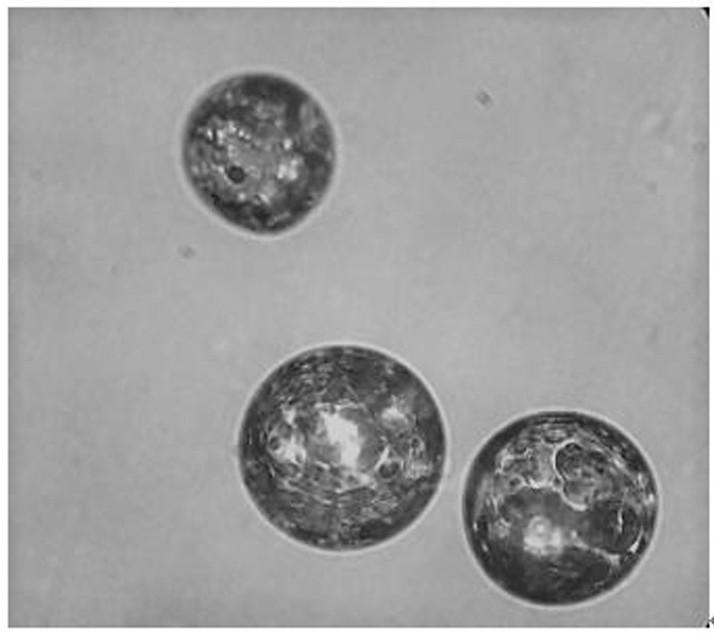

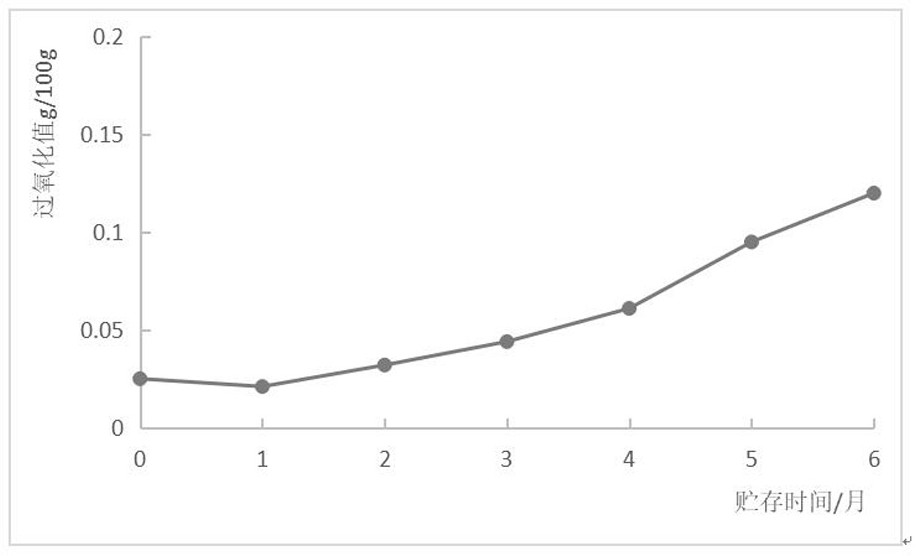

Image

Examples

Embodiment 1

[0031] Embodiment 1: the preparation of a kind of microalgae oil microcapsule, comprises the following steps:

[0032] (1) Wall material dissolution: Weigh casein, porous starch, β-cyclodextrin, chitosan, and mannose oligosaccharides in weights of 20kg, 20 kg, 5 kg, 2.5 kg, and 2 kg respectively, add cold water and stir well , heated to 80°C, kept warm for 30 minutes, fully dissolved into a translucent solution;

[0033] (2) Core material preparation: Antioxidants, stabilizers and emulsifiers were 0.2 kg of hydroxystearin, 0.1 kg of sodium carboxymethyl cellulose, and 0.2 kg of lactic acid fatty acid glycerides, which were added to 50 kg of core material algae oil, Mix evenly, after vacuum degassing, then raise the temperature to 50°C, keep warm for 30min, and stir evenly;

[0034] (3) Core-wall mixing: Mix the above-prepared core material and wall material solution, keep the temperature at 60°C, stir evenly, and prepare the primary emulsion;

[0035] (4) Immediately pass th...

Embodiment 2

[0038] Embodiment 2: the preparation of a kind of microalgae oil microcapsule, comprises the following steps:

[0039] (1) Wall material dissolution: Weigh casein, porous starch, β-cyclodextrin, chitosan, and mannose oligosaccharides in weights of 250 g, 150 g, 50 g, 25 g, and 20 g, respectively, add cold water and stir well , heated to 80°C, kept warm for 30 minutes, fully dissolved into a translucent solution;

[0040] (2) Core material preparation: Antioxidants, stabilizers and emulsifiers were 2 g of hydroxystearin, 1 g of sodium carboxymethyl cellulose, and 2 g of lactic acid fatty acid glycerides, which were added to 500 g of core material algae oil. Mix evenly, after vacuum degassing, then raise the temperature to 50°C, keep warm for 30min, and stir evenly;

[0041] (3) Core-wall mixing: Mix the above-prepared core material and wall material solution, keep the temperature at 60°C, stir evenly, and prepare the primary emulsion;

[0042] (4) Immediately pass the colostr...

Embodiment 3

[0045] Embodiment 3: the preparation of a kind of microalgae oil microcapsule, comprises the following steps:

[0046] (1) Wall material dissolution: Weigh casein, porous starch, β-cyclodextrin, and mannose oligosaccharides in weights of 300 g, 150 g, 25 g, and 20 g, respectively, add cold water and stir evenly, and heat to 90°C. Keep warm for 20 minutes, fully dissolve into a translucent solution;

[0047] (2) Core material preparation: Add 2 g of hydroxystearin, 1 g of carboxymethylcellulose sodium, and 2 g of lactic acid fatty acid glycerides to 500 g of core material microalgae oil as antioxidants, stabilizers, and emulsifiers, and mix Evenly, after vacuum degassing, then heat up to 60°C, keep warm for 20min, and stir evenly;

[0048] (3) Core-wall mixing: Mix the above-prepared core material and wall material solution, keep the temperature at 70°C, stir evenly, and prepare the primary emulsion;

[0049] (4) Immediately pass the colostrum through the colloid mill, keep t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com