Vascular covered stent with anti-thrombus/anti-tumor function and preparation method thereof

A covered stent and anti-tumor technology, which is applied in the direction of blood vessels, stents, and devices with human tubular structures, can solve the problems of drug burst release, restenosis, vascular endothelium, and excessive drug restriction, so as to prevent restenosis and inhibit growth , reduce the effect of blood vessel rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

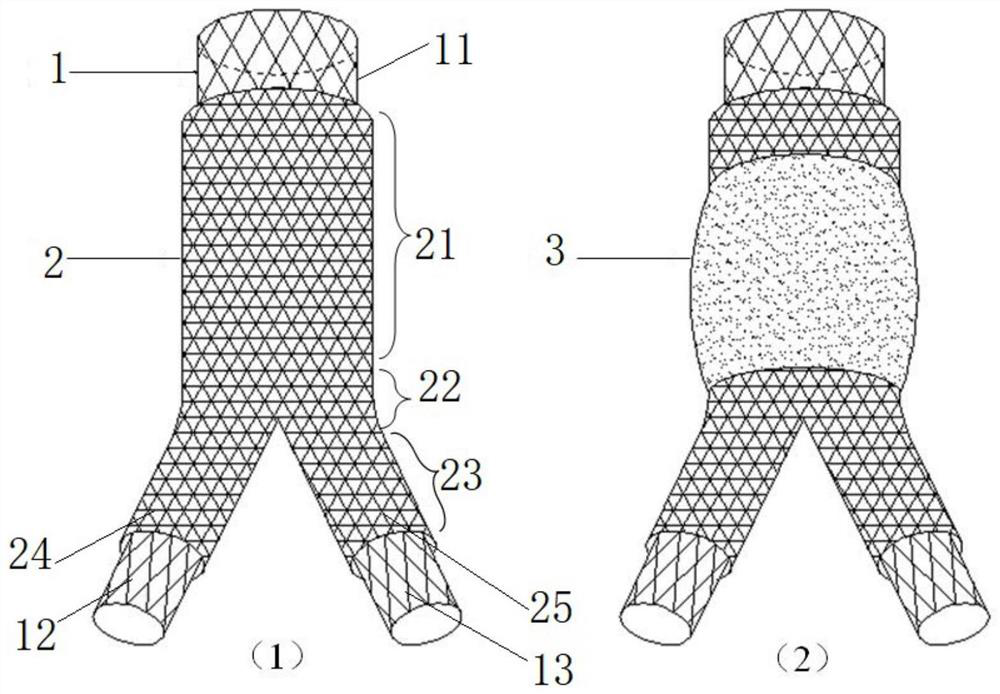

[0053] Such as figure 1 As shown, this implementation case shows a preparation method of antithrombotic / antitumor function vascular stent graft:

[0054] (1) Braiding of the metal stent 1: first, a single nickel-titanium alloy wire is used to weave a tubular stent on a prefabricated mold. Then, the braided metal bracket 1 is subjected to high-temperature setting, and the braided bracket can be removed from the mold. The metal stent 1 is cylindrical, and the alloy wires at both ends of the metal stent 1 are curved to avoid puncturing blood vessels and causing damage. In the present invention, the nickel-titanium alloy wire used has a diameter of 0.1-0.5mm, a braiding angle of 30-75°; a metal coverage rate of 15-60%; and a radial support force of 0.2-2.0N.

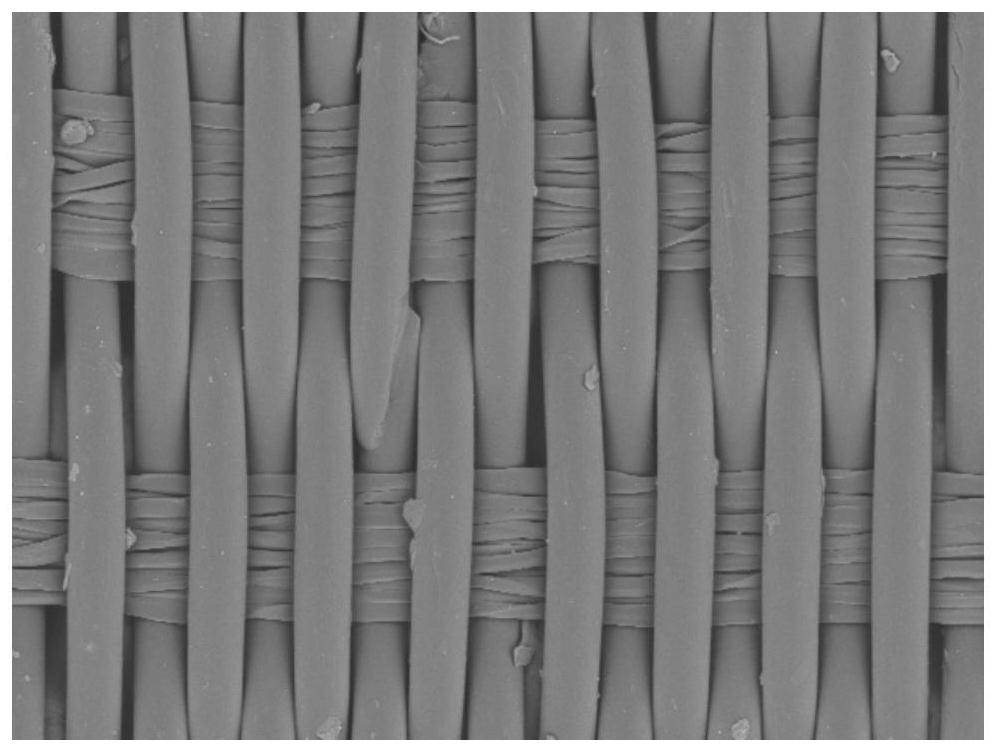

[0055] (2) Preparation of film-coated fabric: fabric film 2 is prepared by weaving method, film-covered 2 thickness is 0.05-0.2 mm, warp and weft material of film-covered 2 is medical polyester filament, warp density is 30...

Embodiment 2

[0065] Such as figure 1 As shown, this implementation case shows a preparation method of an antithrombotic / antitumor function vascular stent graft:

[0066] (1) Braiding of the metal stent 1: the diameter of the nickel-titanium alloy wire used is 0.1-0.5mm, and the braiding angle is 30-75°; the metal coverage is 15-60%; the radial support force is 0.2-2.0N; The shrinkage rate is 10-45%; the elastic recovery rate is 1-5%.

[0067] (2) Preparation of the fabric of the film 2: the film 2 is prepared by a weaving method, the thickness of the film 2 is 0.05-0.2 mm, the warp and weft material of the film 2 is medical polyester filament, and the warp density is 500-2500 Roots / cm, weft density is 500-2500 threads / cm, warp fineness is 15-50D monofilament, weft fineness is 15-50D / 12-48f multifilament, fabric weave is twill weave.

[0068] (3) Coating on the inside and outside: apply antithrombotic coating to the coating 2, dissolve heparin in 1-15% silk fibroin solution, then immerse ...

Embodiment 3

[0070] Such as figure 1 As shown, this implementation case shows a vascular stent graft with antithrombotic / antitumor functions.

[0071] (1) Braiding of the metal stent 1: the diameter of the nickel-titanium alloy wire used is 0.1-0.5mm, and the braiding angle is 30-75°; the metal coverage is 15-60%; the radial support force is 0.2-2.0N; The shrinkage rate is 10-45%; the elastic recovery rate is 1-5%.

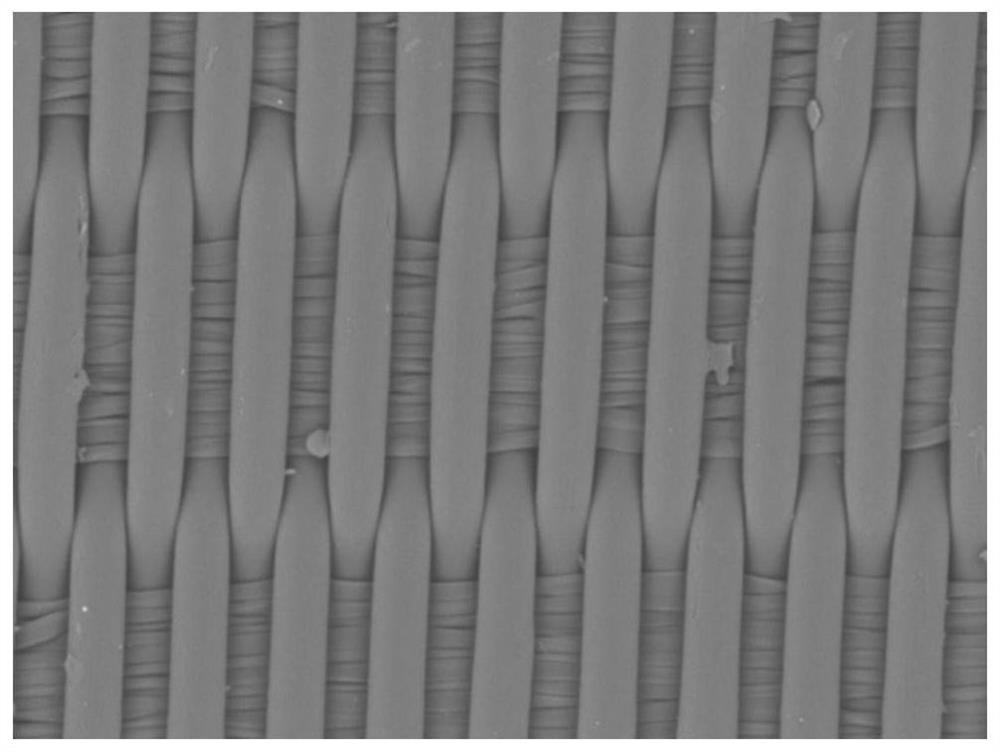

[0072] (2) Preparation of film-covered fabric: film-2 thickness is 0.05-0.2mm, warp and weft material of film-2 is medical spandex filament, warp density is 500-3000 / cm, weft density is 500-3000 / cm cm, the warp fineness is 15-50D monofilament, the weft fineness is 15-50D / 12-48f multifilament, and the fabric weave is satin weave.

[0073] (3) Coating on the inside and outside: antithrombotic treatment is carried out to the vascular stent prepared by the present invention, the specific method is: the stent is soaked in heparin sodium saline for 5-30min, then rinsed with distil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Radial support force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com