Method for preparing electromagnetic wave absorption material from hydrotalcite-based composite nanofiber

A technology for composite nanofibers and absorbing materials, which is applied in the field of preparing electromagnetic wave absorbing materials from hydrotalcite-based composite nanofibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

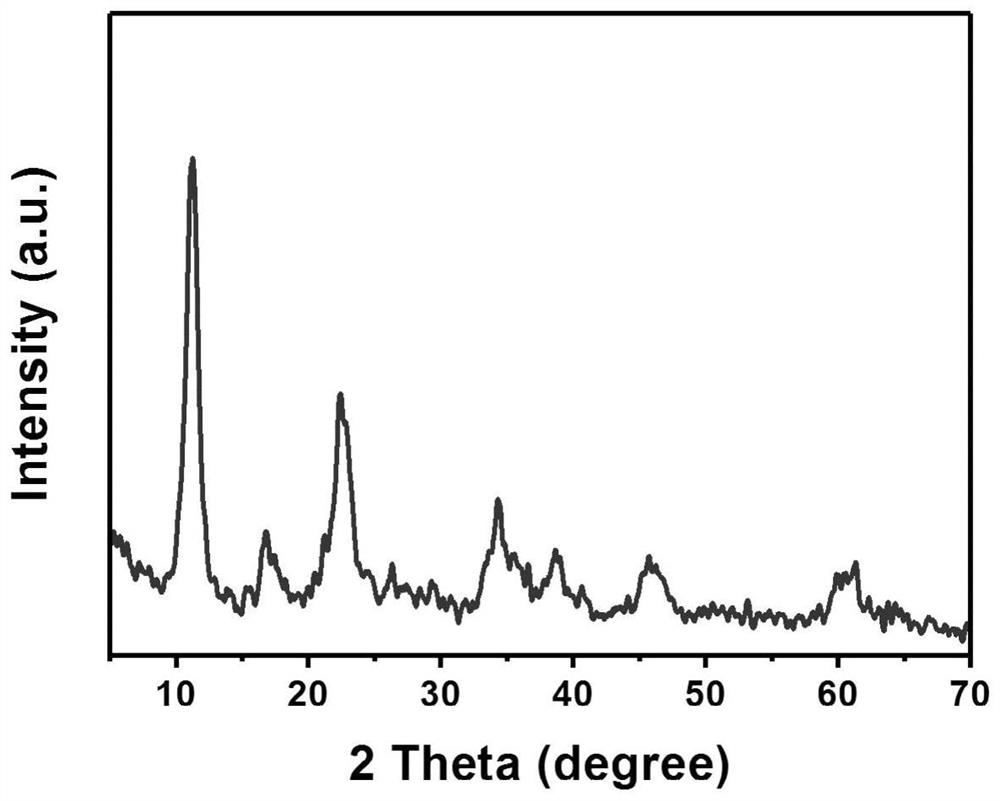

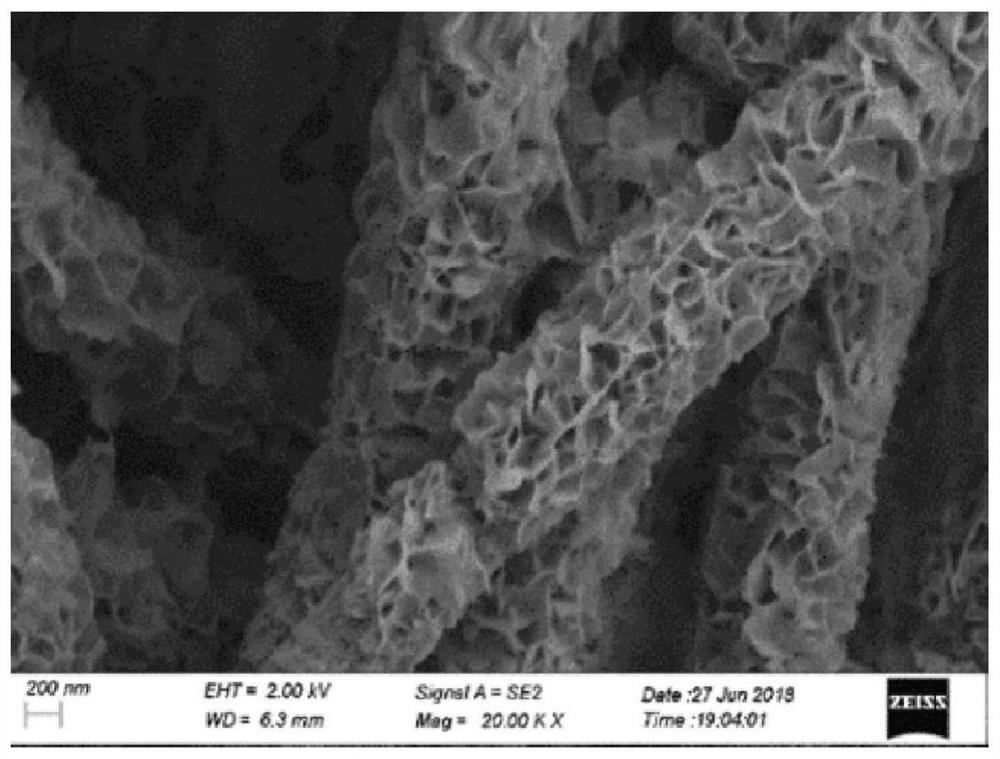

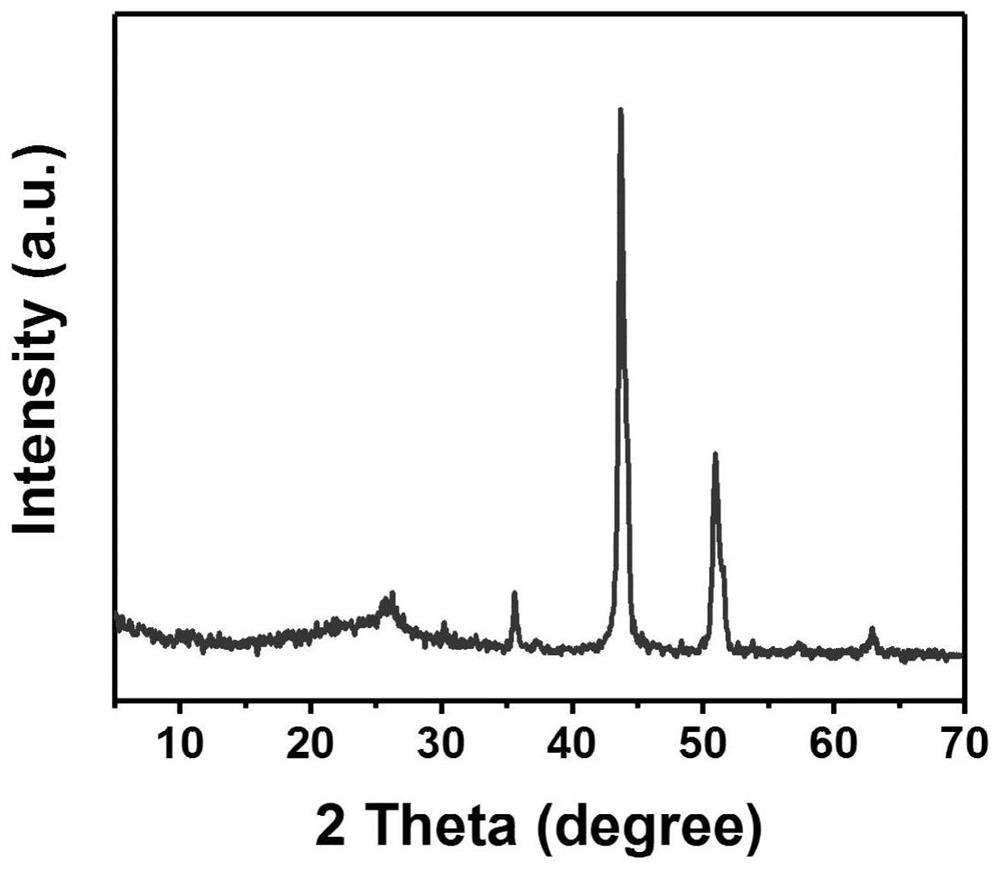

Method used

Image

Examples

Embodiment 1

[0027] (1) Measure 10mL of N,N-dimethylformamide, add 0.8g of polyacrylonitrile and 0.08g of FeOOH to it to make a solution, which is the outer layer solution; measure 10mL of N,N-dimethylformamide base formamide, adding 0.8g polyacrylonitrile and 0.05g carbon nanotubes to it to prepare a solution, which is the core layer solution; the two solutions are respectively added to the syringe, using a coaxial needle, the inner needle and the core layer The solution is connected, the outer needle is connected to the outer solution, the electric field voltage is set to 18kV, the receiving distance is 15cm, and the solution flow rate is 1.5mL / h; the fiber membrane obtained by spinning is dried in a vacuum oven at 60°C for 8h to obtain FeOOH-doped Polyacrylonitrile fiber membrane;

[0028] (2) prepare the mixed salt solution of nickel chloride and ferric chloride, Ni 2+ and Fe 3+ The molar ratio is 3:1, Ni 2+ The concentration of urea is 0.015mol / L, the amount of urea is twice the am...

Embodiment 2

[0033] With embodiment 1, difference is: in step (1), the consumption of carbon nanotube is 0.1g; In step (2), replace nickel chloride and ferric chloride with nickel nitrate and ferric nitrate; In step (3), The time and temperature of the pre-oxidation treatment are: 300°C pre-oxidation treatment for 2 hours.

Embodiment 3

[0035] With embodiment 1, difference is: in step (1), the consumption of FeOOH is 0.1g, the voltage of described high voltage electrospinning method is 15kV; In step (2), the temperature of described reaction is 100 ℃, and reaction time 14h; in step (3), the time and temperature of roasting treatment are: 900°C roasting treatment for 3h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Return loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com