Preparation method of hollow microspheres and application thereof

A hollow and composite microsphere technology, applied in the fields of polymer materials and biomedical engineering, can solve the problems of uneven structure of microspheres, long degradation time, high density of microspheres, etc., and achieve easy industrial production, simple preparation process, avoidance of high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The invention provides a method for preparing hollow PLGA microspheres. The method includes the following steps:

[0065] 1) PLGA is dissolved in an organic solvent to obtain a PLGA solution;

[0066] 2) adding the porogen to the PLGA solution in step 1), and homogenizing to form a mixed solution;

[0067] 3) adding the mixed solution in step 2) into the PVA aqueous solution below the liquid level, and stirring to form an emulsion, and after removing the porogen and the organic solvent, a residue is obtained;

[0068] 4) collecting and washing the residue in step 3) to obtain hollow PLGA microspheres with a diameter of 100-500 μm;

[0069] 5) surface activation of the hollow PLGA microspheres in step 4) to obtain activated hollow PLGA microspheres;

[0070] 6) Mix and react the activated hollow PLGA microspheres in step 5) with the gelatin solution, collect, wash and dry to obtain hollow PLGA-gelatin composite microspheres.

[0071] In some embodiments of the presen...

Embodiment 1

[0133] Example 1: Preparation of hollow PLGA microspheres.

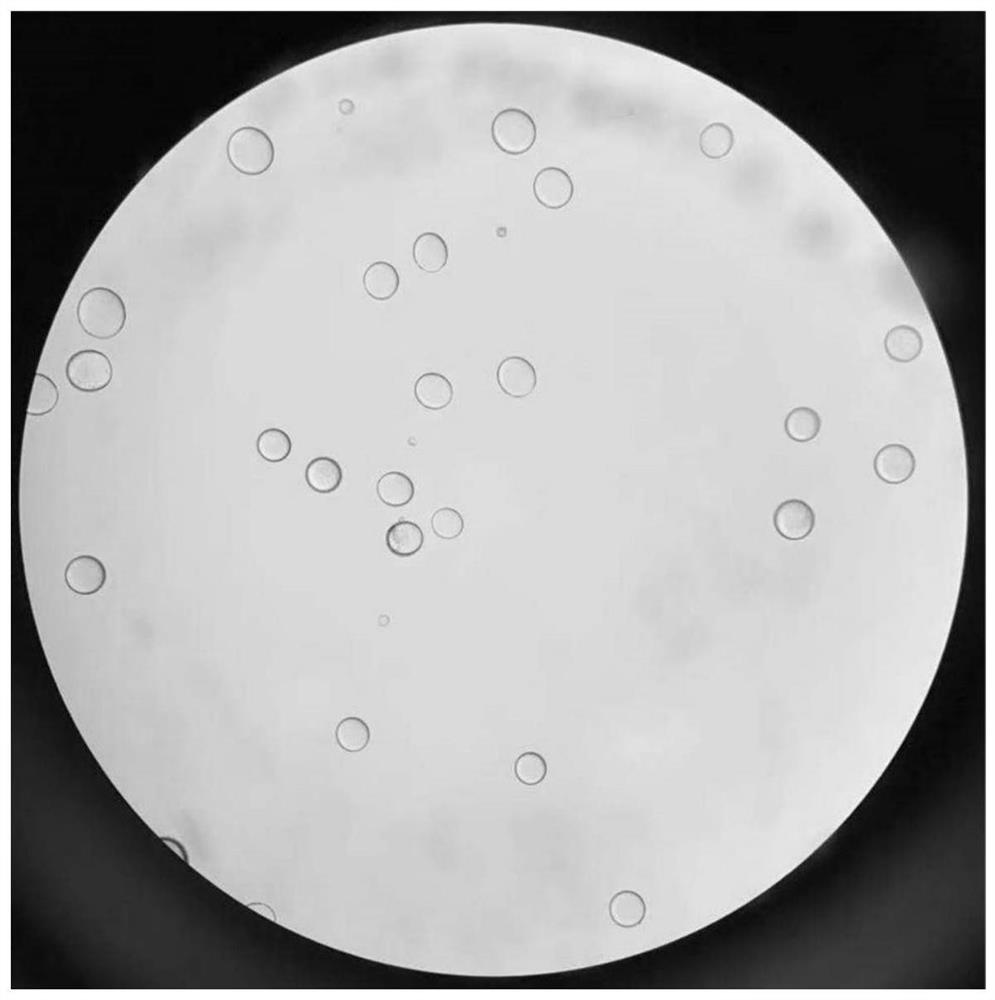

[0134] Weigh PLGA (50:50, Mw=30000-50000Da, carboxyl-terminated) (1 g) and dissolve it in dichloromethane (20 mL). Add absolute ethanol (10 mL), and homogenize for 60 seconds with a homogenizer at a speed of 13000 rpm. With the syringe pump that has 25G, the injection needle of inner diameter 0.25mm, mixed solution is injected in the PVA aqueous solution (2L) that mass concentration is 0.5% with the speed of 10mL / min, and mechanical stirring speed is 200rpm, stirs 12h, volatilizes to remove two Chloromethane. Washed 3 times with double distilled water, collected by centrifugation, obtained as Figures 1A-1B The hollow PLGA microspheres shown.

[0135] The resulting hollow PLGA microspheres have a diameter of 100 μm and a density of 1.00-1.10 g / cm 3 .

Embodiment 2

[0136] Example 2: Preparation of hollow PLGA microspheres.

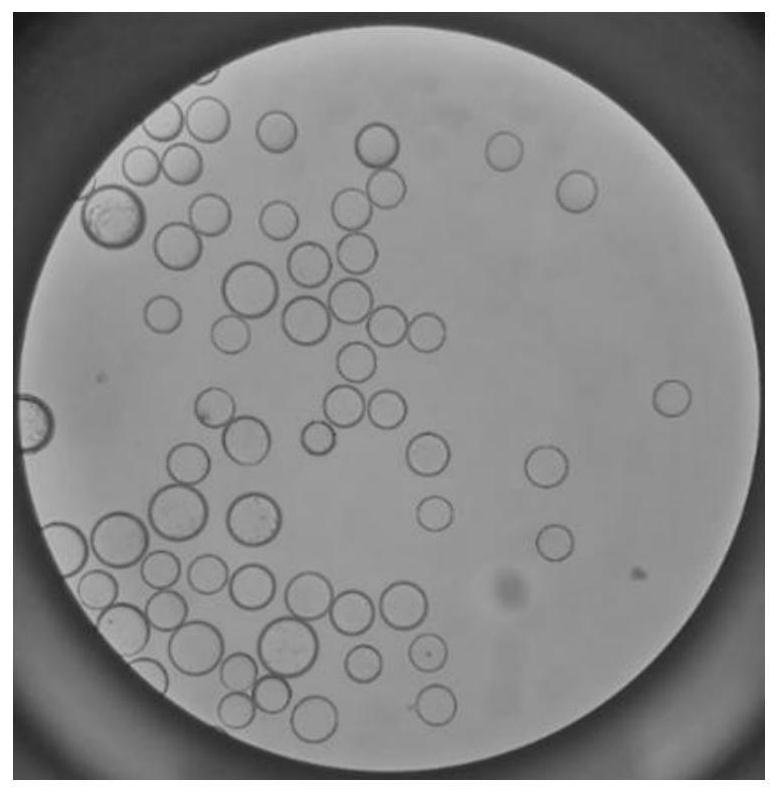

[0137] Weigh PLGA (75:25, Mw=66000~105000Da, ester-terminated) (1g), dissolve in dichloromethane (20mL), add absolute ethanol (10mL), homogenize for 60s with a homogenizer, and homogenize The speed is 13000rpm. With the syringe pump that has 25G, the injection needle of inner diameter 0.25mm, mixed solution is injected in the PVA aqueous solution (2L) that mass concentration is 0.5% with the speed of 10mL / min, and mechanical stirring speed is 200rpm, stirs 12h, volatilizes to remove two Chloromethane. Washed 3 times with double distilled water, collected by centrifugation, obtained as figure 2 The hollow PLGA microspheres shown.

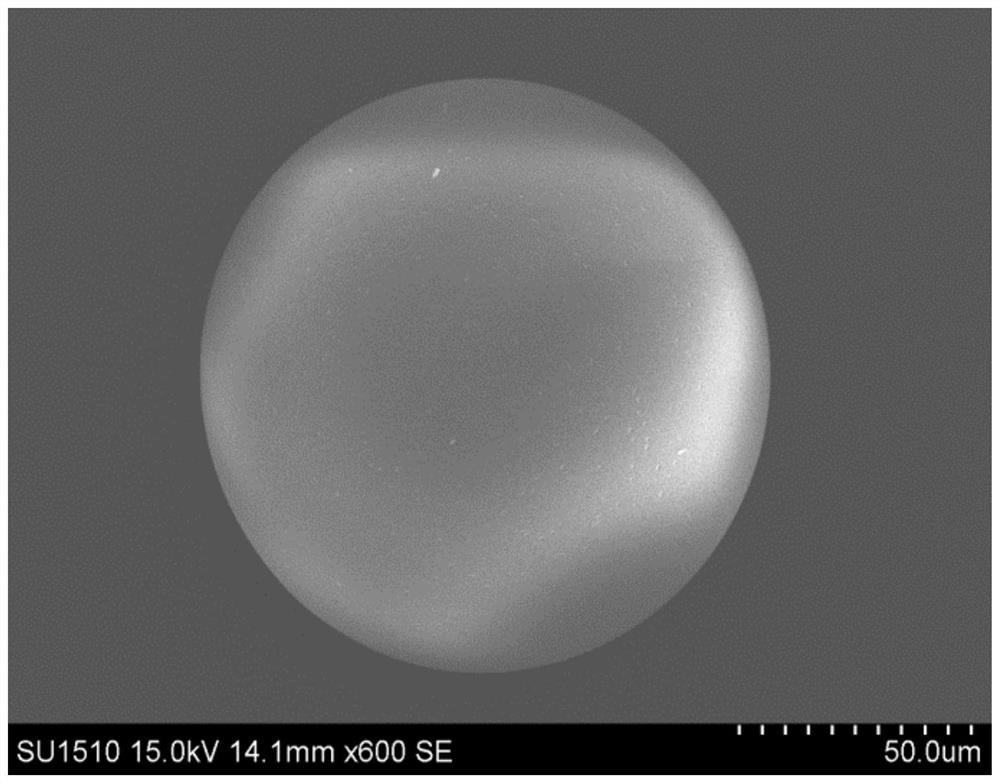

[0138] Depend on Figure 3A-3B It can be seen that the diameter of the hollow PLGA microspheres prepared by the above method is about 150 μm, the size distribution is uniform, the surface is relatively smooth (under a magnified view of 1.50kX), the outer wall is thinner, and the interi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com