Antimony sulfide film preferentially growing in direction of one-dimensional chain belt and preparation method of antimony sulfide film

A technology of antimony sulfide and thin film, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc. It can solve the problems such as difficult preparation of antimony sulfide thin film, and achieve short-process preparation, overcome crystal growth, and high photoelectric conversion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

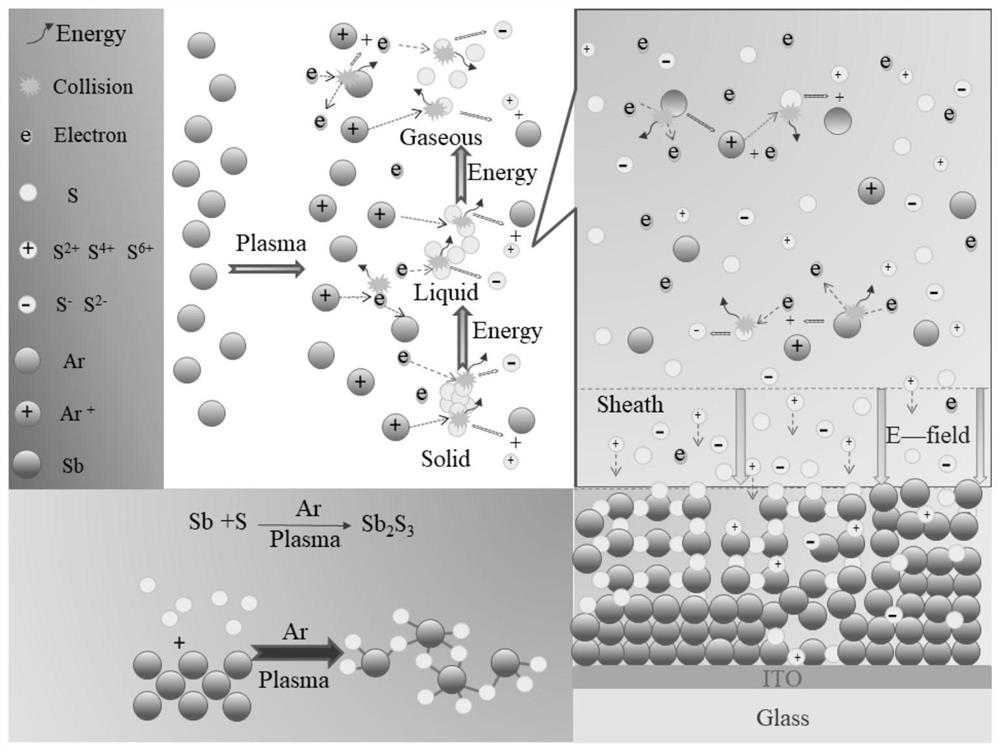

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: A kind of preparation method of the antimony sulfide thin film that preferentially grows along the one-dimensional chain belt direction, concrete steps are as follows:

[0036] (1) Prepare metal antimony thin film by magnetron sputtering method:

[0037] Install the antimony target in the magnetron sputtering equipment, put the cleaned soda-lime glass sheet into the sample stage, and set the power at 20W, the sputtering time at 100min, and the working gas pressure at 0.9Pa in an argon atmosphere Preparing metal antimony thin films under the conditions;

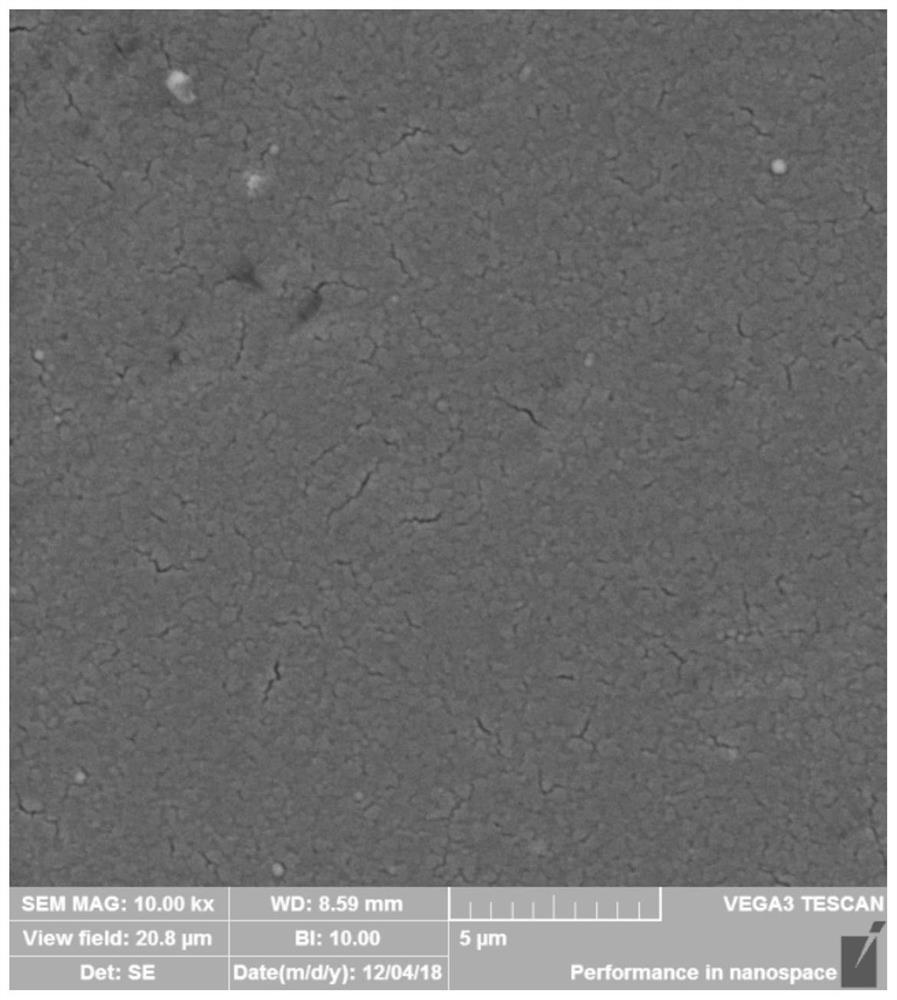

[0038] The surface SEM figure of the metal antimony thin film of this embodiment is shown in image 3 ,From image 3 It can be seen that the metal antimony thin film prepared by magnetron sputtering has the characteristics of smooth surface and compactness, and is suitable for preparing antimony sulfide thin film by directional heat treatment in plasma sulfur atmosphere;

[0039] (2) Prepara...

Embodiment 2

[0046] Embodiment 2: A kind of preparation method of the antimony sulfide thin film that preferentially grows along the one-dimensional chain belt direction, concrete steps are as follows:

[0047] (1) Prepare metal antimony thin film by chemical bath deposition method:

[0048] Take 3 grams of antimony trichloride solid raw material, 6 milliliters of ammonia water, and 25 milliliters of triethanolamine in a small beaker. After the dissolution and complexation are complete, pour it into a 250 milliliter volumetric flask and adjust the pH of the solution with hydrochloric acid or sodium hydroxide. 7.4, put the solution in a 500 ml beaker, put washed and dried Mo-coated glass (square resistance value is 20 Ω) in the beaker as the experimental base material; After reacting for 10min, the Mo-coated glass was taken out, rinsed with secondary water and dried to obtain a thin film attached to the Mo-coated glass as Sb(OH) 3 ; Sb(OH) 3 Thin film through H 2 Reduction to pr...

Embodiment 3

[0056] Embodiment 3: A kind of preparation method of the antimony sulfide thin film that preferentially grows along the direction of one-dimensional chain belt, concrete steps are as follows:

[0057] (1) Preparation of metal antimony thin films by spray pyrolysis:

[0058] Accurately weigh 20g of analytically pure SbCl 3 Dissolve in 250ml of dilute HCl with a mass fraction of 5% 3 In the solution, under the protective atmosphere of argon, the SbCl 3 The solution is atomized into aerosol micro-droplets, and a flat electric furnace with Mo conductive glass is placed in the system. , the tail gas is discharged after being neutralized by the absorbing bottle of lye; the film on the flat electric furnace is further heated in H 2 Metal antimony film can be obtained by reduction under atmosphere for 30 minutes;

[0059] (2) Preparation of antimony sulfide film by directional heat treatment in plasma sulfur atmosphere:

[0060] The sulfur source is placed in the ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com