Sulfur/MXene/graphene composite material and preparation method and application thereof

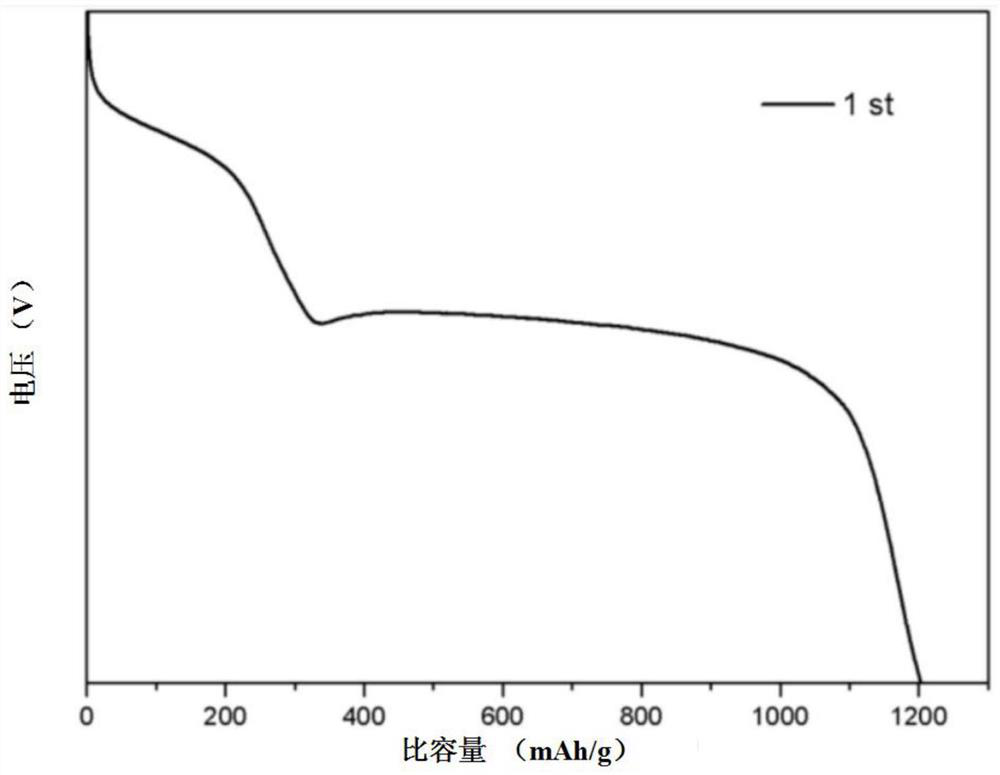

A composite material and graphene technology, applied in the field of materials, can solve the problems of insufficient ability to adsorb elemental sulfur, easy dissolution of intermediate polysulfides, and low utilization rate of sulfur in active substances, and achieve fast interlayer ion channels , buffer volume effect to maintain, increase the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Preparation of MXene material: Weigh 2g of lithium fluoride (LiF) and dissolve it in 40ml of hydrochloric acid (HCl), stir constantly, and slowly add 2g of aluminum carbide titanium (Ti 3 AlC 2 ), continue to stir, and react at room temperature for 25h, and the resulting reaction product is washed with deionized water and ethanol respectively until the solution is neutral, and then it is placed in deionized water for ultrasonic dispersion treatment (temperature is 25°C, power 200W, time 5 hours), and finally freeze-drying (condensation temperature lower than -40°C, vacuum degree lower than 10Pa, time 18h) to obtain MXene material.

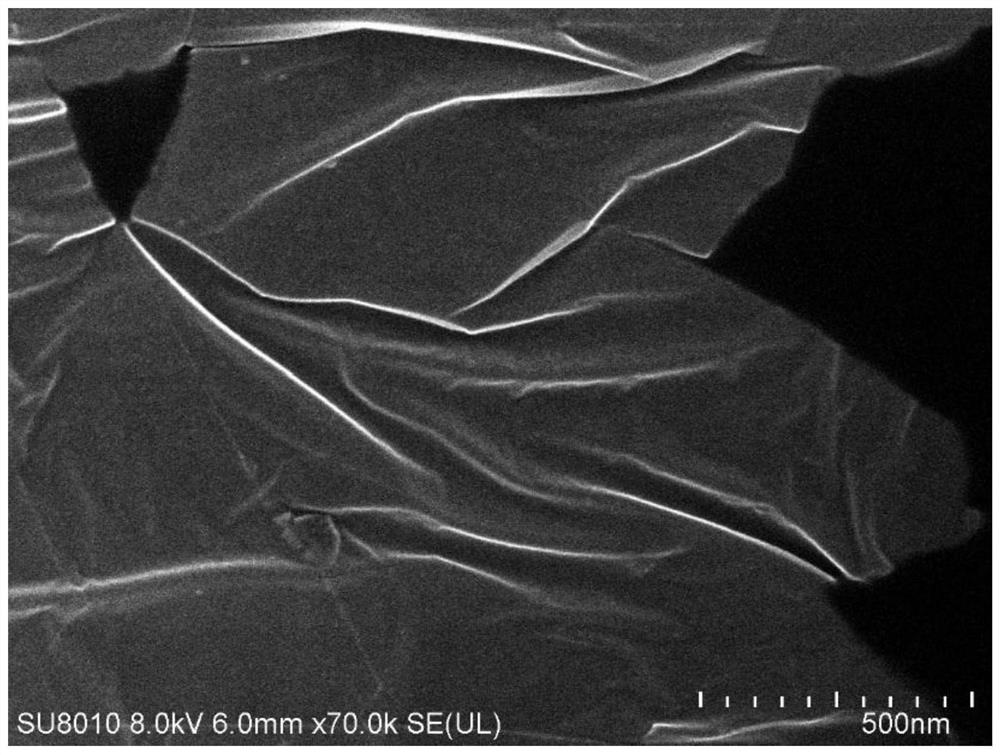

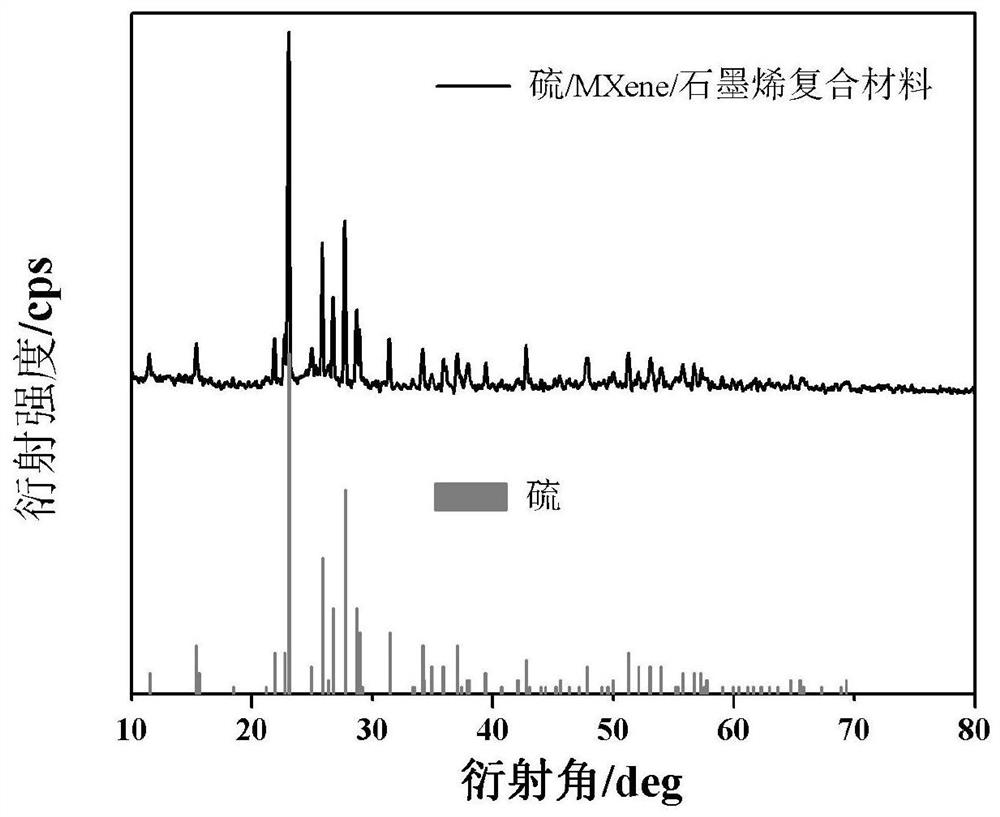

[0053] Preparation of sulfur / MXene / graphene composite material: Weigh 20mg of MXene material, 5mg of graphene and 75mg of elemental sulfur for mixing and grinding, then sieve the resulting mixed powder and put it into a closed container with oxygen value <0.1ppm and water content <0.1ppm In the process, the melt-diffusion reaction was carri...

Embodiment 2

[0060] Preparation of MXene material: Weigh 4g of lithium fluoride (LiF) and dissolve it in 80ml of hydrochloric acid (HCl), stir constantly, and slowly add 4g of aluminum carbide titanium (Ti 3 AlC 2 ), continue to stir, and react at room temperature for 25h, and the resulting reaction product is washed with deionized water and ethanol respectively until the solution is neutral, and then it is placed in deionized water for ultrasonic dispersion treatment (temperature is 25°C, power 200W, time 5 hours), and finally freeze-drying (condensation temperature lower than -40°C, vacuum degree lower than 10Pa, time 18h) to obtain MXene material.

[0061] Preparation of sulfur / MXene / graphene composite material: Weigh 10mg MXene material, 10mg graphene and 80mg elemental sulfur for mixing and grinding, then sieve the resulting mixed powder and put it into a closed container with oxygen value <0.1ppm and moisture <0.1ppm In the process, the melt diffusion reaction was carried out at 160...

Embodiment 3

[0064] Preparation of MXene material: Measure 40ml of hydrofluoric acid (HF), slowly add 2g of aluminum carbide titanium (Ti 3 AlC 2 ), continue to stir, react at room temperature for 25h, wash the obtained reaction product with deionized water and ethanol respectively until the solution is neutral, then place it in deionized water for ultrasonic dispersion treatment (temperature is below 25°C, power 200W, time 5 hours), and finally freeze-drying treatment (condensation temperature is lower than -40°C, vacuum degree is less than 10Pa, time 18h) to obtain MXene material.

[0065] Preparation of sulfur / MXene / graphene composite material: Weigh 25mg MXene, 15mg graphene and 60mg elemental sulfur for mixing and grinding, then sieve the resulting mixed powder and put it into a closed container with oxygen <0.1ppm and humidity <0.1 ppm , melt-diffusion reaction was carried out at 150° C., the sample was taken out after 10 h of reaction, and the sulfur / MXene / graphene composite materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com