Method for improving thermal stability of alpha-AlH3

A thermal stability, -alh3 technology, applied in the direction of explosives, etc., can solve problems such as decomposition phenomena, achieve low decomposition rate, improve thermal stability, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

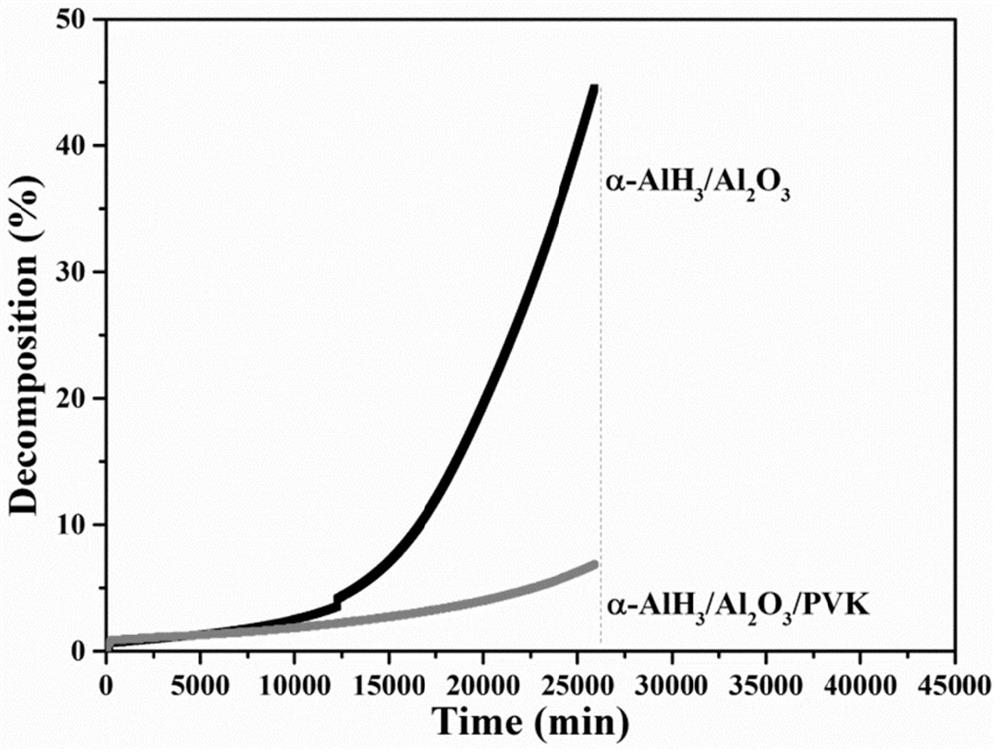

[0031] This embodiment discloses a method to improve α-AlH 3 Thermal stability methods, including for α-AlH 3 Carry out pickling treatment, and then use carbazole group-containing polymer to coat the pickled α-AlH 3 to increase α-AlH 3 thermal stability.

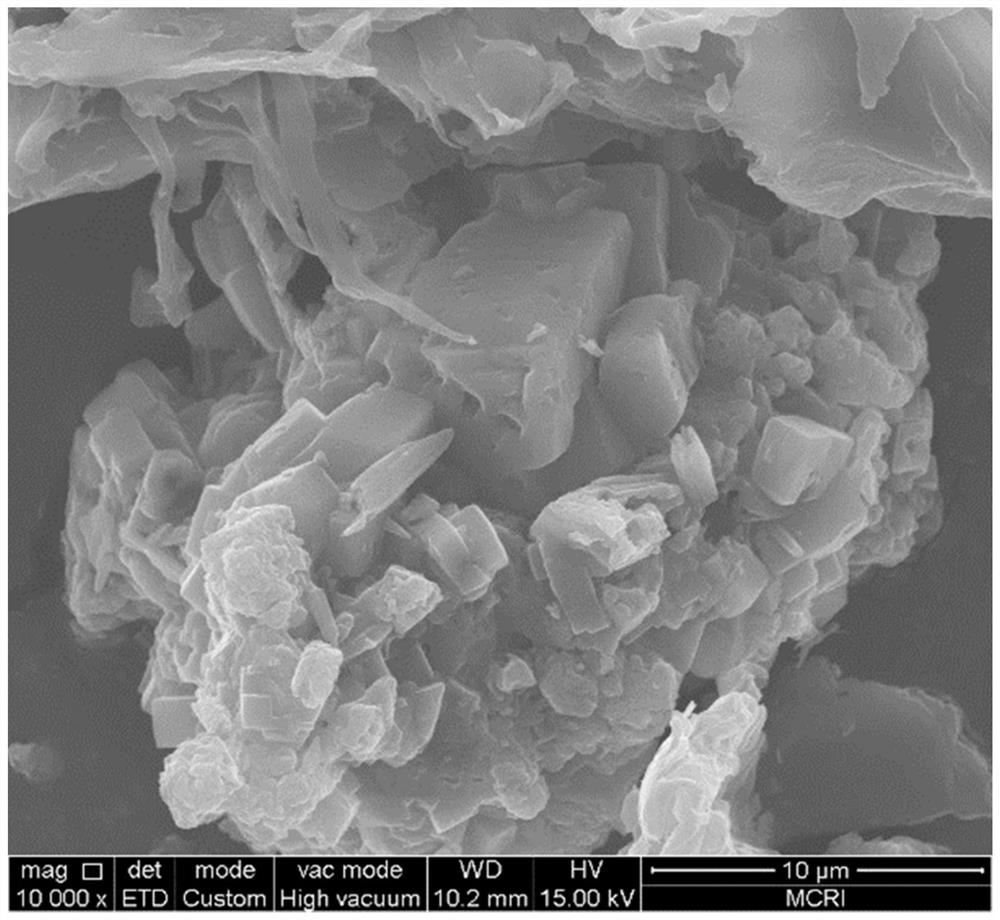

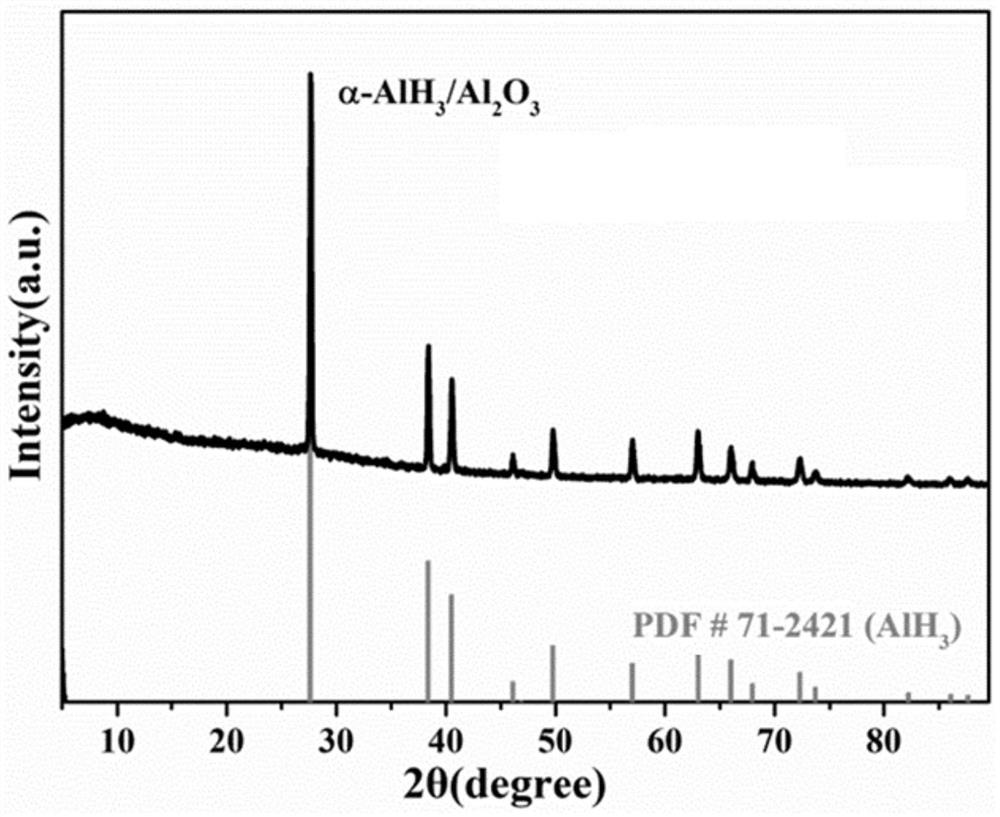

[0032] Pickling treatment includes α-AlH 3 Add to the acid solution and stir, filter, wash and dry in turn to obtain α-AlH 3 / Al 2 o 3 .

[0033] α-AlH coated with carbazole group-containing polymer after pickling 3 Specifically include: dissolving the polymer containing carbazole group in an organic solvent to obtain a polymer solution system, and then pickling the α-AlH 3 Soaking in said polymer solution system, stirring, filtering, washing and drying.

[0034] The polymer containing carbazole group is a single one of polyvinylcarbazole, poly(9-vinylcarbazole), poly(n-vinylcarbazole) and poly(N-ethyl-2-vinylcarbazole). components or mixed components.

[0035] In this embodiment, the acid solution is dilute hydro...

Embodiment 2

[0041] Same as Example 1, the difference is that poly(9-vinylcarbazole) and α-AlH 3 The mass ratio is 1:5, and the volume fraction of dilute hydrochloric acid solution is 8%.

Embodiment 3

[0043] (1) configuration volume fraction is the dilute hydrochloric acid solution of 5%; Get the α-AlH of wet method synthesis 3 Add dilute hydrochloric acid solution, stir and filter, wash with ethanol three times, and finally freeze-dry to obtain off-white powder sample, that is, α-AlH 3 / Al 2 o 3 .

[0044] (2) Take 200mg poly(N-ethyl-2-vinylcarbazole) and disperse it in chloroform solvent, stir and dissolve; then take 500mg α-AlH 3 / Al 2 o 3 Add it, stir and disperse for 2h~6h, filter and wash 3 times with chloroform, and finally freeze-dry to obtain off-white powder sample, that is, α-AlH 3 / Al 2 o 3 / PVK. The stirring speed is 200-1000rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com