High-performance fluorescent functionalized polyarylethernitrile, preparation method and application thereof

A poly(arylene ether nitrile), high-performance technology is applied in the field of high-performance fluorescent functionalized poly(arylene ether nitrile) and its preparation, which can solve the problems of inability to improve the luminous band of poly(arylene ether nitrile) and low luminous efficiency of poly(arylene ether nitrile), and achieves the Good film formation, fluorescence intensity enhancement, spectrum broadening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

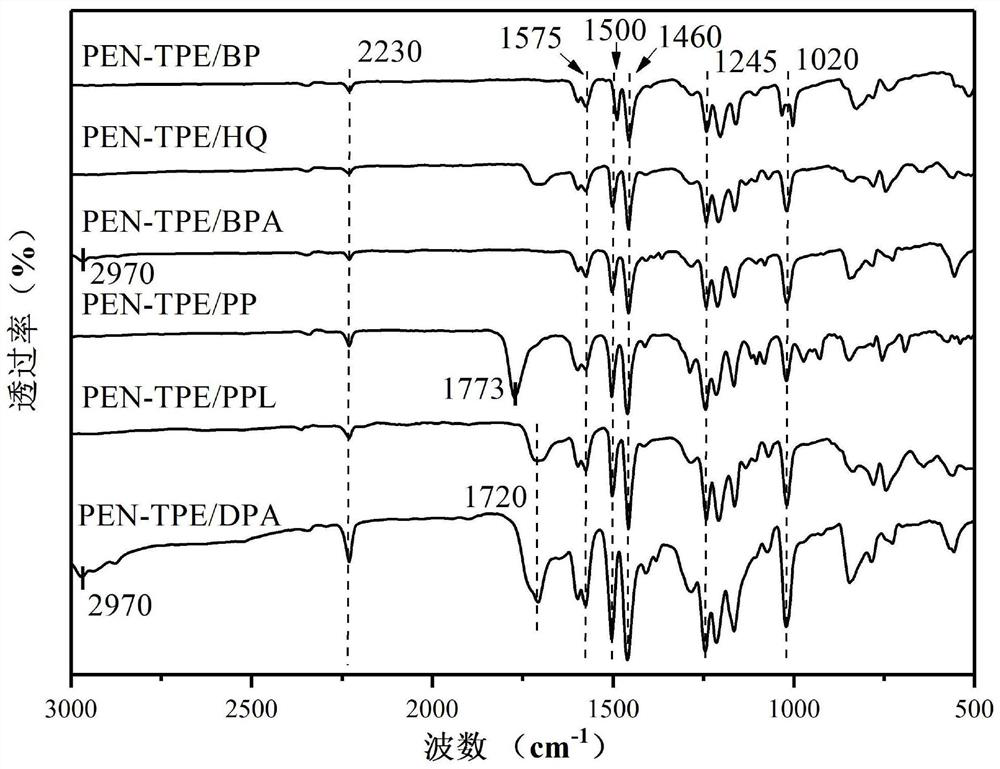

[0028] The present embodiment provides a kind of tetraphenylethylene type polyarylether nitrile copolymer PEN-TPE / BP, and its structural formula is:

[0029]

[0030] This embodiment also provides the synthetic method of this copolymer PEN-TPE / BP, and the steps are as follows:

[0031] Add 0.20mmol tetraphenylethylene bisphenol derivative monomer, 19.80mmol biphenyl bisphenol, 20.00mmol 2,6-dichlorobenzonitrile, 30.00mmol anhydrous potassium carbonate, 16.00mL N-methylpyrrolidone and 6.00mL toluene Put in a 100mL three-necked flask with a mechanical stirring device, a thermometer, a water separator and a condensing device; mechanically stir to mix and dissolve the reactants, then raise the temperature to 130-150°C for azeotropic dehydration for 2 hours, and then gradually raise the temperature to 180-200°C React for 2 to 3 hours; after the reaction is completed, slowly pour the obtained viscous product into dilute hydrochloric acid solution to precipitate a strip-shaped pol...

Embodiment 2

[0033] The present embodiment provides a kind of tetraphenylethylene type polyarylether nitrile copolymer PEN-TPE / HQ, and its structural formula is:

[0034]

[0035] This embodiment also provides the synthetic method of this copolymer PEN-TPE / HQ, and the steps are as follows:

[0036] Add 0.20mmol of tetraphenylethylene bisphenol derived monomer, 19.80mmol of hydroquinone, 20.00mmol of 2,6-dichlorobenzonitrile, 30.00mmol of anhydrous potassium carbonate, 14.00mL of N-methylpyrrolidone and 4.70mL of toluene Put in a 100mL three-necked flask with a mechanical stirring device, a thermometer, a water separator and a condensing device; mechanically stir to mix and dissolve the reactants, then raise the temperature to 130-150°C for azeotropic dehydration for 2 hours, and then gradually raise the temperature to 180-200°C React for 2 to 3 hours; after the reaction is completed, slowly pour the obtained viscous product into dilute hydrochloric acid solution to precipitate a strip-s...

Embodiment 3

[0038] The present embodiment provides a kind of tetraphenylethylene type polyarylether nitrile copolymer PEN-TPE / BPA, and its structural formula is:

[0039]

[0040] This embodiment also provides the synthetic method of this copolymer PEN-TPE / BPA, and the steps are as follows:

[0041]Add 0.20mmol tetraphenylethylene bisphenol derived monomer, 19.80mmol bisphenol A, 20.00mmol 2,6-dichlorobenzonitrile, 30.00mmol anhydrous potassium carbonate, 20.00mL N-methylpyrrolidone and 6.70mL toluene Put in a 100mL three-necked flask with a mechanical stirring device, a thermometer, a water separator and a condensing device; mechanically stir to mix and dissolve the reactants, then raise the temperature to 130-150°C for azeotropic dehydration for 2 hours, and then gradually raise the temperature to 180-200°C for reaction 2 to 3 hours; after the reaction is completed, slowly pour the obtained viscous product into dilute hydrochloric acid solution to precipitate a strip-shaped polyaryle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com