Photosensitive resin composition and preparation method thereof, photosensitive organic vehicle and yellow light paste

A technology of photosensitive resin and organic carrier, which is applied in the field of photosensitive organic carrier and yellow light paste, photosensitive resin composition and its preparation, and can solve problems such as insufficient adhesion, inability to form conductive network, and rough lines. Achieve the effects of increasing molecular weight and cross-linking density, not easy to separate and separate out, good wetting and dispersing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

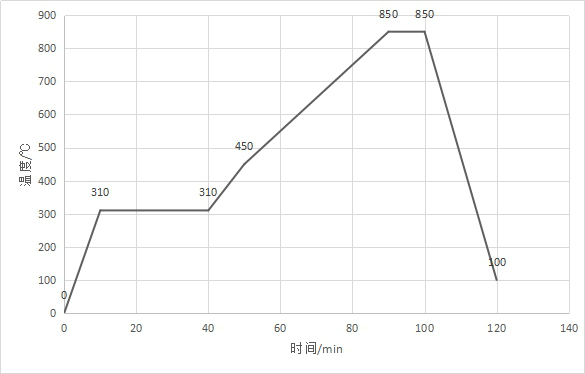

Image

Examples

preparation example Construction

[0047] The present invention also proposes a preparation method of a photosensitive resin composition, comprising the following steps:

[0048] Mix acidic monomers, high oxygen content monomers, backbone monomers, and thermal initiators to obtain a homogeneous mixture;

[0049] Dropping the homogeneous mixture into the reaction solvent preheated to 80°C to 90°C, and maintaining the reaction at 80°C to 90°C with stirring to obtain the base;

[0050] Add photocurable monomers to the base, and react at 70°C-80°C for 2-3h to obtain a photosensitive resin mixture.

[0051] Specifically, the acidic monomer, high oxygen content monomer, skeleton monomer and thermal initiator are first poured into a beaker, ultrasonically dissolved and mixed to obtain a homogeneous mixture. Then add the reaction solvent into the glass reaction kettle with a reflux condenser, heat at a constant temperature to 80°C~90°C, pass argon for protection, and stir at a speed range of 100~200RPM. Afterwards, t...

Embodiment 1

[0073] (1) Preparation of photosensitive resin composition:

[0074] In parts by mass, ultrasonically dissolve and mix 8 parts of methacrylic acid, 20 parts of polyethylene glycol methacrylate, 8 parts of n-butyl methacrylate, 4 parts of styrene, and 1 part of azobisethylbutyronitrile , to obtain a homogeneous mixture. Add 57 parts of propylene glycol monomethyl ether into a glass reactor with a reflux condenser, heat at a constant temperature to 85° C., protect with argon, and stir at 150 RPM. The aforementioned homogeneous mixture was gradually dropped into a glass reaction kettle through a dropping funnel, kept at 85° C., and stirred for 4 hours to obtain a photosensitive resin base. Then, 10 parts of triglycidyl methacrylate was added to the base, kept at 70° C., stirred for 2 hours, and reacted to obtain a photosensitive resin composition.

[0075] (2) Preparation of photosensitive organic carrier:

[0076] In parts by mass, weigh 55 parts of photosensitive resin compo...

Embodiment 2

[0088] (1) Preparation of photosensitive resin composition:

[0089] In parts by mass, 7 parts of methacrylic acid, 12 parts of polypropylene glycol methacrylate, 9 parts of methyl methacrylate, 3 parts of n-butyl acrylate, and 2 parts of azodiethylbutyronitrile were ultrasonically dissolved and mixed, A homogeneous mixture was obtained. Add 56 parts of ethylene glycol monobutyl ether into a glass reactor with a reflux condenser, heat it at a constant temperature to 85°C, protect it with argon, and stir at a speed of 150 RPM. The aforementioned homogeneous mixture was gradually dropped into a glass reaction kettle through a dropping funnel, kept at 85° C., and stirred for 4 hours to obtain a photosensitive resin base. Then, 3 parts of hydroxyethyl methacrylate and 8 parts of hydroxypropyl methacrylate were added to the base, kept at 70°C, stirred for 2 hours, and reacted to obtain a photosensitive resin composition.

[0090] (2) Preparation of photosensitive organic carrier:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com