A kind of high safety solid state electrolyte and its preparation method and application

A solid electrolyte, safe technology, applied in the direction of solid electrolyte, non-aqueous electrolyte, non-aqueous electrolyte battery, etc., can solve problems such as battery damage, achieve the effect of preventing deterioration, improving interface impedance, and preventing short circuit in the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

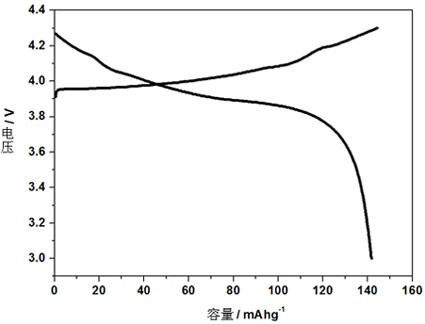

Embodiment 1

[0104] Under the condition of no water or oxygen, 2,3-Dihydroxypropyl acrylate, 1,6-hexandiisocyanate and lithium difluoroacetate borate were prepared into a homogeneous solution according to the mass ratio of 2:8:2. The solution was then assembled into LiCoO 2 / Li battery and place the battery in a thermostat at 80 ℃ for polymerization for 10 hours. The thermal decomposition temperature of the electrolyte is as high as 350 ℃, and there is no melting point. The assembled LiCoO 2 / The specific discharge capacity of Li button battery is 140 MAH / g at 60 ℃, 120 MAH / g at room temperature and 150 MAH / g at 120 ℃. The specific discharge capacity at 150 ℃ is reduced to 40 MAH / g, and the ionic conductivity of polymer electrolyte is one order of magnitude lower than that at 100 ℃.

Embodiment 2

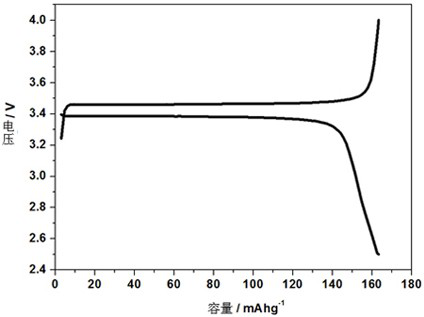

[0106] Under the condition of no water or oxygen, 2,3-Dihydroxypropyl methacrylate, isoflurone diisocyanate and lithium trifluoromethylsulfonimide were prepared into a homogeneous solution according to the mass ratio of 2:8:5. The solution was then assembled into LiFePO 4 / Li battery and place the battery in a thermostat at 60 ℃ for polymerization for 12 hours. The assembly temperature of LiFePO is 350 ℃, and there is no thermal decomposition of LiFePO 4 / The specific discharge capacity of Li button battery is 150mah / g at 60 ℃, 130mah / g at room temperature and 160mah / g at 120 ℃. The specific discharge capacity at 150 ℃ is reduced to 50 MAH / g, and the ionic conductivity of polymer electrolyte is significantly lower than that at 100 ℃.

Embodiment 3

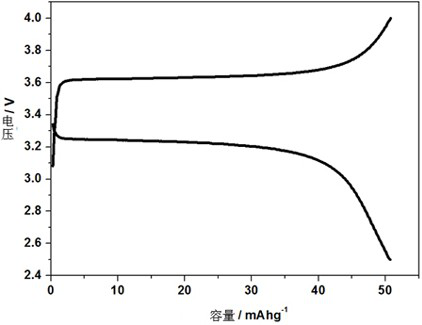

[0108] Under the condition of no water or oxygen, hydroxyethyl methacrylate, isoflurone diisocyanate and lithium trifluoromethylsulfonimide were prepared into a homogeneous solution according to the mass ratio of 2:8:2. The solution was then assembled into LiFePO 4 / Li battery and place the battery in a thermostat at 60 ℃ for polymerization for 10 hours. The thermal decomposition temperature of the electrolyte is as high as 350 ℃, and there is no melting point. LiFePO is assembled 4 / The specific discharge capacity of Li button battery is 140 MAH / g at 60 ℃, 120 MAH / g at room temperature and 150 MAH / g at 120 ℃. The specific discharge capacity at 150 ℃ is reduced to 50 MAH / g, and the ionic conductivity of polymer electrolyte is significantly lower than that at 100 ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com