Method for simultaneously removing various impurity ions in zinc hydrometallurgy waste electrolyte

A technology of hydrometallurgy and waste electrolyte, which is applied in the field of non-ferrous metallurgy, can solve the problems of large waste slag and wastewater output, high cost, and unsatisfactory removal of impurity ions, etc., and achieves low output of intermediate waste slag, The effect of fast reaction speed and high removal efficiency of impurity ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

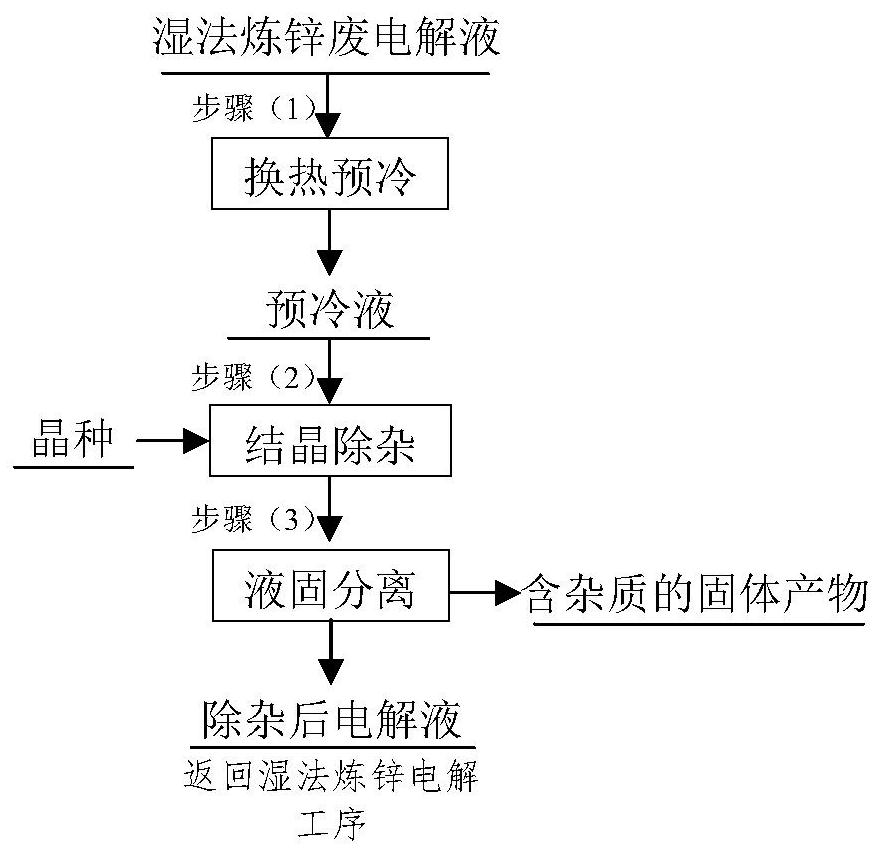

[0030] A method for removing impurity ions in the waste electrolytic solution of wet zinc smelting, the specific steps are as follows:

[0031] (1) Heat exchange and pre-cooling: Take the waste electrolyte produced in the zinc electrolysis process of the wet zinc smelting plant. The physical and chemical properties of the electrolyte are: temperature 40°C, sulfuric acid concentration 180g / L, zinc ion concentration 45g / L, The lead ion concentration is 9.2mg / L, the calcium ion concentration is 45mg / L, the silicon dioxide concentration is 120mg / L, the fluoride ion concentration is 110mg / L, and the antimony ion concentration is 0.3mg / L. Put this spent electrolyte in 1m 3 The flow rate of / h is pumped into the tubular heat exchanger, and the calcium chloride solution with a temperature of -15°C is used as the refrigerant for heat exchange. .

[0032] (2) Crystallization and impurity removal: the pre-cooling liquid produced in step (1) was 3 The flow rate of / h is pumped into the...

Embodiment 2

[0036] A method for removing impurity ions in the waste electrolytic solution of wet zinc smelting, the specific steps are as follows:

[0037](1) Heat exchange and pre-cooling: Take the waste electrolyte produced in the zinc electrolysis process of the wet zinc smelting plant. The physical and chemical properties of the electrolyte are: temperature 38°C, sulfuric acid concentration 170g / L, zinc ion concentration 46g / L, The lead ion concentration is 7.5mg / L, the calcium ion concentration is 82mg / L, the silicon dioxide concentration is 110mg / L, the fluoride ion concentration is 152mg / L, and the antimony ion concentration is 0.36mg / L. Put this spent electrolyte in 1m 3 The flow rate of / h is pumped into the tubular heat exchanger, and the calcium chloride solution with a temperature of -20°C is used as the refrigerant for heat exchange. .

[0038] (2) Crystallization and impurity removal: the pre-cooling liquid produced in step (1) was 3 The flow rate of / h is pumped into the...

Embodiment 3

[0042] A method for removing impurity ions in the waste electrolytic solution of wet zinc smelting, the specific steps are as follows:

[0043] (1) Heat exchange and pre-cooling: Take the waste electrolyte produced in the zinc electrolysis process of the wet zinc smelting plant. The physical and chemical properties of the electrolyte are: temperature 37°C, sulfuric acid concentration 150g / L, zinc ion concentration 50g / L, The lead ion concentration is 6.3mg / L, the calcium ion concentration is 95mg / L, the silicon dioxide concentration is 135mg / L, the fluoride ion concentration is 95mg / L, and the antimony ion concentration is 0.35mg / L. Put this spent electrolyte in 1m 3 The flow rate of / h is pumped into the tubular heat exchanger, and the calcium chloride solution with a temperature of -15°C is used as the refrigerant for heat exchange. .

[0044] (2) Crystallization and impurity removal: the pre-cooling liquid produced in step (1) was 3 The flow rate of / h is pumped into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com