Hollow TiO2@C composite microsphere and preparation method thereof

A titanium dioxide and carbon composite technology, used in the preparation of microspheres, microcapsule preparations, secondary batteries, etc., can solve the problems of ion channels that are not suitable for rapid sodium ion migration, capacity loss, poor conductivity, etc., to ensure structural stability. and fast kinetic properties, method simplicity, and the effect of short ion migration distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

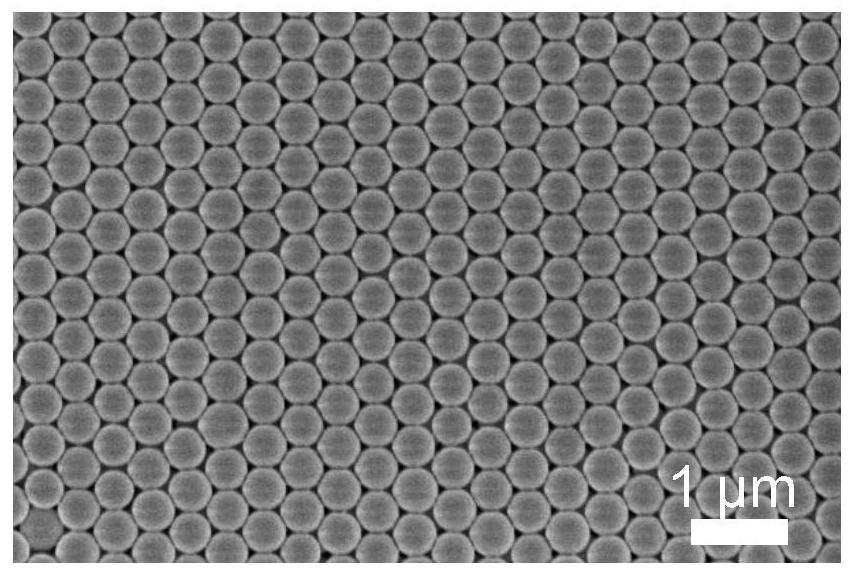

[0053] Example 1: Synthesis of silica nanospheres with uniform size

[0054] Add ethyl orthosilicate (0.04g / mL) to the mixture of water and ethanol (V:V, 2:15) containing ammonia (0.2mol / L), stir at 25°C for 4h, hydrolyze completely, and centrifuge. Wash with ethanol to obtain silica nanospheres with uniform size.

[0055] The particle size of the obtained silica nanospheres was 300 nm.

Embodiment 2

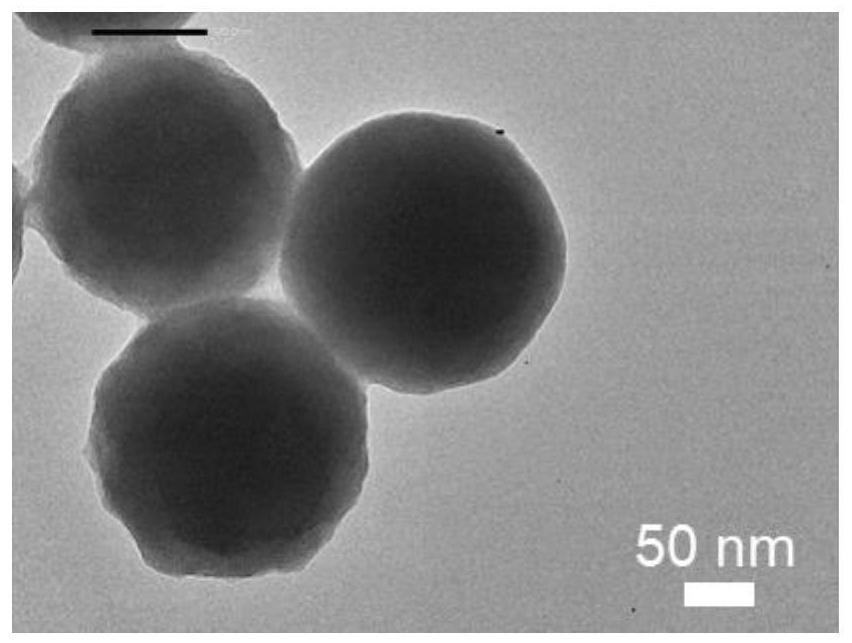

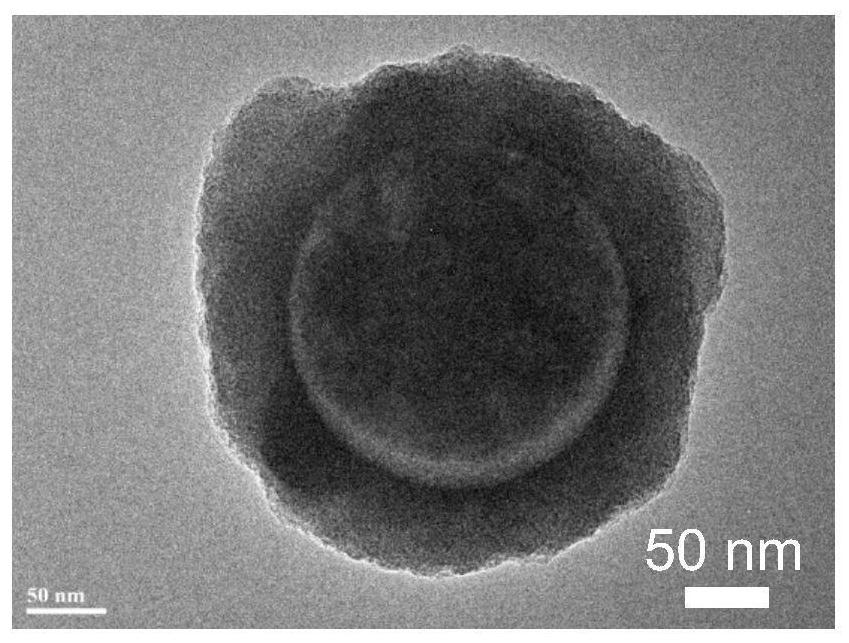

[0056] Example 2: Synthesis of silica@titania core-shell microspheres with a shell thickness of 20nm

[0057] Disperse the silica nanospheres in ethanol containing hexadecylamine (8 mg / mL) and ammonia water (4.5 mg / mL) under the action of ultrasound, then add titanium isopropoxide (5 mg / mL) and stir at 25 °C After 1 hour, the hydrolysis and polycondensation were completed, centrifuged, and washed with ethanol to obtain silica@titania core-shell structure microspheres.

[0058] The thickness of the titanium dioxide shell layer of the obtained silica@titania core-shell structure microspheres is 20 nm.

Embodiment 3

[0059] Embodiment 3: the shell layer thickness is the synthesis of 50nm silica@titanium dioxide core-shell structure microsphere

[0060] Disperse the silica nanospheres in ethanol containing hexadecylamine (8 mg / mL) and ammonia water (4.5 mg / mL) under the action of ultrasound, then add titanium isopropoxide (12 mg / mL) and stir at 25 °C After 1 hour, the hydrolysis and polycondensation were completed, centrifuged, and washed with ethanol to obtain silica@titania core-shell structure microspheres.

[0061] The thickness of the titanium dioxide shell layer of the obtained silica@titania core-shell structure microspheres is 50 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com