Iron-doped tellurium nickel sulfide electrocatalyst and preparation method thereof

A technology of tellurium sulfide and iron doping, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, electrodes, etc., can solve the problems of difficult electrocatalytic performance and performance to be improved, achieve high electrocatalytic activity, increase electrochemical Good surface area and oxygen evolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

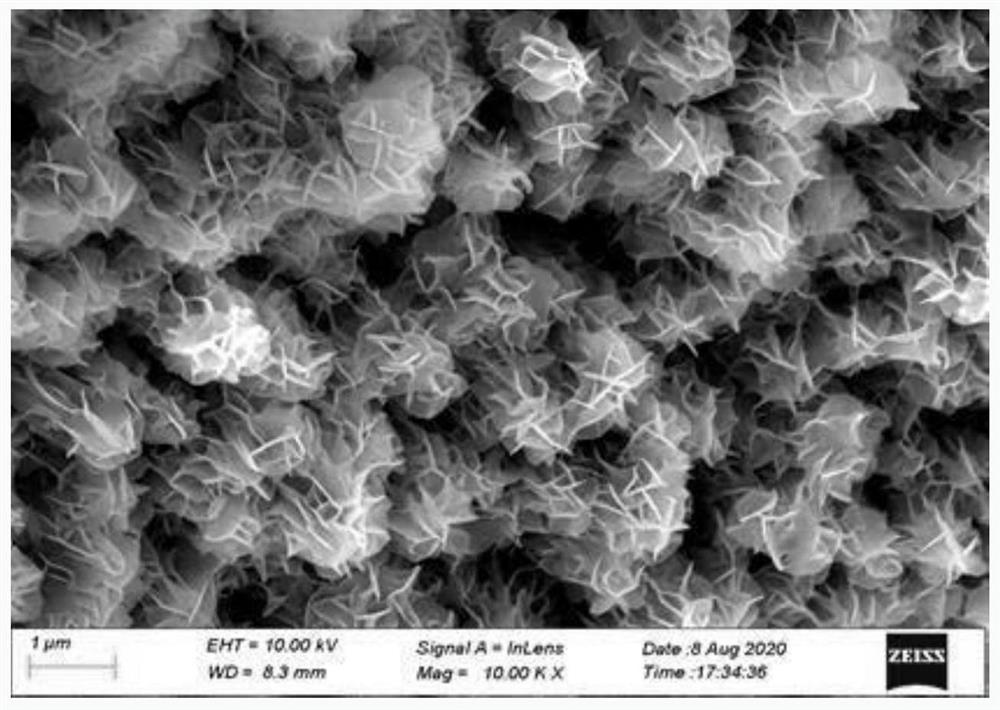

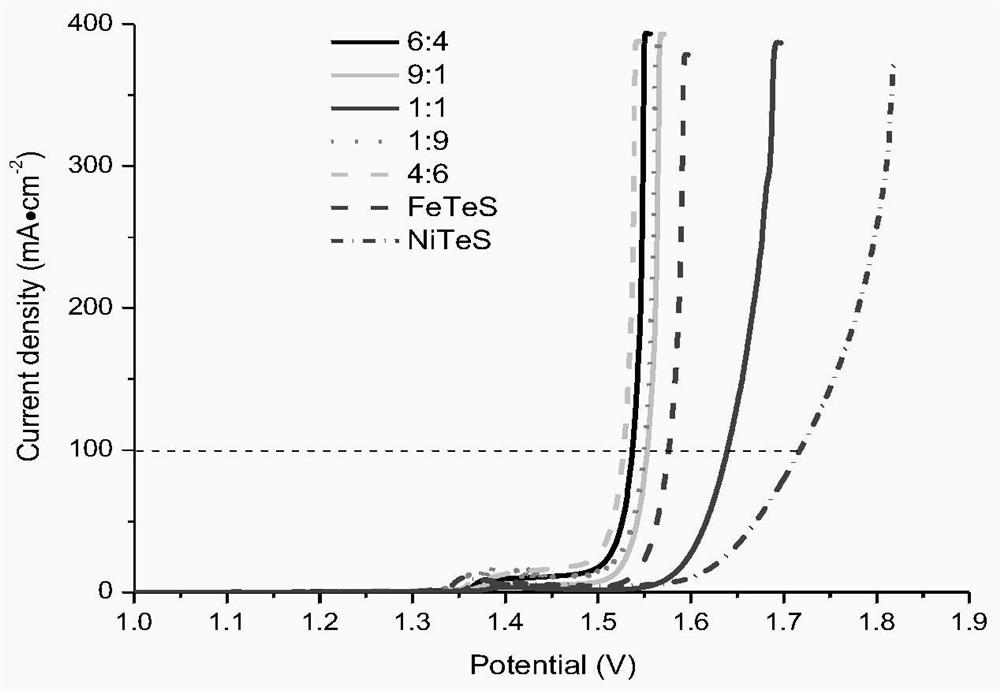

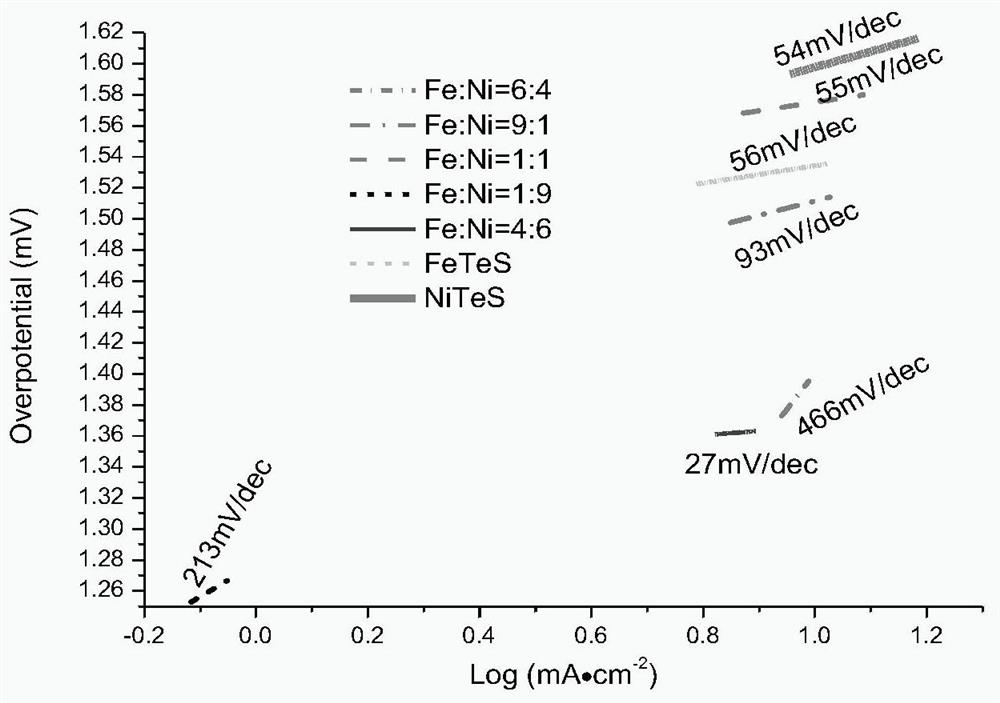

Image

Examples

Embodiment 1

[0032] 1. Pretreatment of nickel foam

[0033] The nickel foam was activated with 3mol / L hydrochloric acid solution at 60°C for half an hour, followed by ultrasonic cleaning with ethanol and deionized water for 10 minutes.

[0034] 2. Weighing of telluride, nickel compound and iron compound

[0035] Weigh 0.0665g of sodium tellurite, 0.7272g of iron nitrate, and 0.3490g of nickel nitrate into a 50mL reaction kettle.

[0036] 3. Weighing of sulfide

[0037] Put the iron-nickel-tellurium composite grown on the surface of nickel foam into a 50mL reactor containing 0.6g of sodium sulfide.

[0038] Preparation of 4.1mol / L KOH solution

[0039] Weigh 28.055g of potassium hydroxide into a 100mL beaker, add distilled water, dissolve and stir with a glass rod, transfer to a 500mL volumetric flask to constant volume after cooling.

[0040] 5. Preparation of iron-doped tellurium nickel sulfide electrocatalysts with different iron and nickel contents grown on the surface of nickel foa...

Embodiment 2

[0046] 1. Pretreatment of nickel foam

[0047] The nickel foam was activated with 3mol / L hydrochloric acid solution at 60°C for half an hour, followed by ultrasonic cleaning with ethanol and deionized water for 10 minutes.

[0048] 2. Weighing of telluride, nickel compound and iron compound

[0049] Weigh 0.0665g of sodium tellurite, 1.0908g of iron nitrate, and 0.0872g of nickel nitrate into a 50mL reaction kettle.

[0050] 3. Weighing of sulfide

[0051] Put the iron-nickel-tellurium composite grown on the surface of nickel foam into a 50mL reactor containing 0.6g of sodium sulfide.

[0052] Preparation of 4.1mol / L KOH solution

[0053] Weigh 28.055g of potassium hydroxide in a 100mL beaker, add distilled water, dissolve and stir with a glass rod, transfer to a 500mL volumetric flask to constant volume after cooling.

[0054] 5. Preparation of iron-doped tellurium nickel sulfide electrocatalysts with different iron and nickel contents grown on the surface of nickel foam ...

Embodiment 3

[0060] 1. Pretreatment of nickel foam

[0061] The nickel foam was activated with 3mol / L hydrochloric acid solution at 60°C for half an hour, followed by ultrasonic cleaning with ethanol and deionized water for 10 minutes.

[0062] 2. Weighing of telluride, nickel compound and iron compound

[0063] Weigh 0.0665g of sodium tellurite, 0.1212g of iron nitrate, and 0.0872g of nickel nitrate into a 50mL reaction kettle.

[0064] 3. Weighing of sulfide

[0065] Put the iron-nickel-tellurium composite grown on the surface of nickel foam into a 50mL reactor containing 0.6g of sodium sulfide.

[0066] Preparation of 4.1mol / L KOH solution

[0067] Weigh 28.055g of potassium hydroxide in a 100mL beaker, add distilled water, dissolve and stir with a glass rod, transfer to a 500mL volumetric flask to constant volume after cooling.

[0068] 5. Preparation of iron-doped tellurium nickel sulfide electrocatalysts with different iron and nickel contents grown on the surface of nickel foam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com