Polyvinylidene fluoride mixed matrix membrane with photocatalytic self-cleaning performance as well as preparation method and application of polyvinylidene fluoride mixed matrix membrane

A technology of polyvinylidene fluoride and mixed matrix membrane, which is applied in the field of membrane separation, can solve the problems of polyvinylidene fluoride membrane membrane fouling, etc., and achieve the effect of improved hydrophilicity, increased rejection rate, and high rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A preparation method of a polyvinylidene fluoride (PVDF) mixed matrix membrane with photocatalytic self-cleaning performance, comprising the following steps:

[0043] 1) SnO 2 -Cu 2 Preparation of O nanocomposites: cuprous chloride (CuCl 2 ), stannous chloride dihydrate (SnCl 2 2H 2 O) and hydrochloric acid were added to deionized water, and ultrasonic 15-45min to obtain a mixed solution, then the pH of the mixed solution was adjusted to 7-12, the reducing agent hydrazine hydrate was added and reacted at room temperature for 1-4h, and the obtained product was centrifuged Finally, take the precipitate and wash it with ethanol, then vacuum-dry it at 40-80°C, and finally calcinate it at 100-400°C for 1-4h in an argon atmosphere to obtain SnO 2 -Cu 2 O nanocomposites;

[0044] Among them, CuCl 2 with SnCl 2 2H 2 The molar ratio of O is (1-4):(0.1-2); the addition amount of hydrochloric acid is 10-30mL / mol Cu, and the concentration of hydrochloric acid is 30-40mol / L...

Embodiment 1

[0050] This example is used to prepare SnO 2 -Cu 2 O nanocomposite material, concrete preparation method is as follows:

[0051] 1) Add 0.01mol CuCl 2 , 0.005mol SnCl 2 2H 2 0 and 0.2mL of 35mol / L hydrochloric acid were added to 200mL of deionized water, and ultrasonically treated for 30min to obtain a mixed solution;

[0052] 2) Add ammonia water to the mixed solution until the solution pH=9.0, then add 0.2mL hydrazine hydrate, and carry out the reduction reaction at room temperature for 2h;

[0053] 3) After the product was washed with ethanol, it was dried in vacuum at 60°C, and then the dry powder was calcined at 200°C for 2h under the protection of argon to obtain SnO 2 -Cu 2 O nanocomposites.

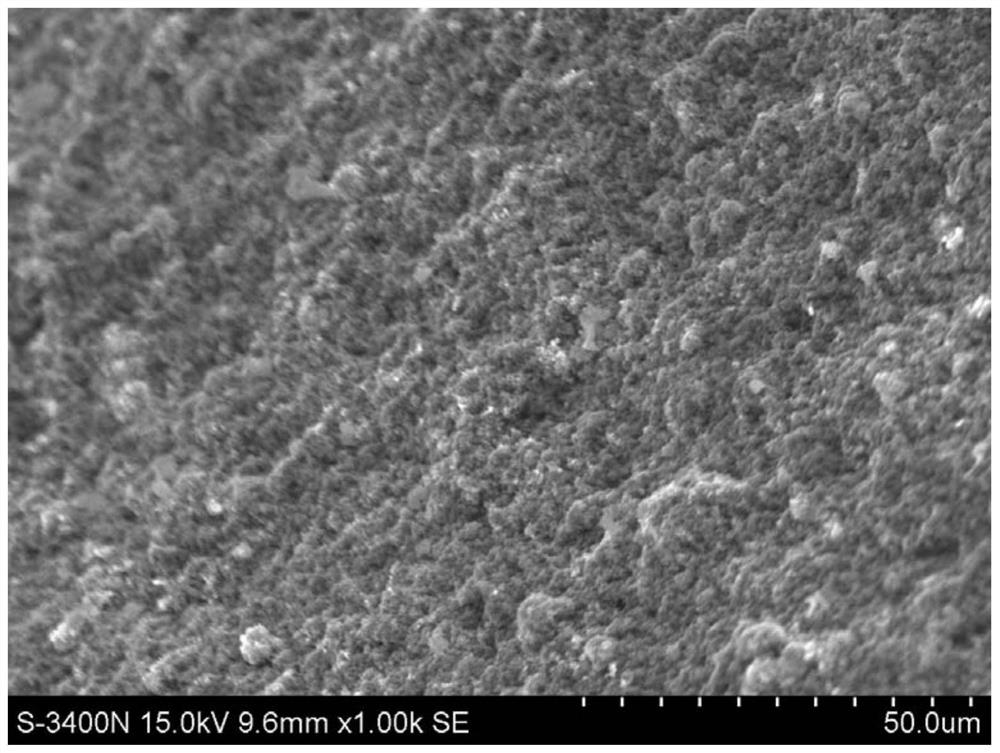

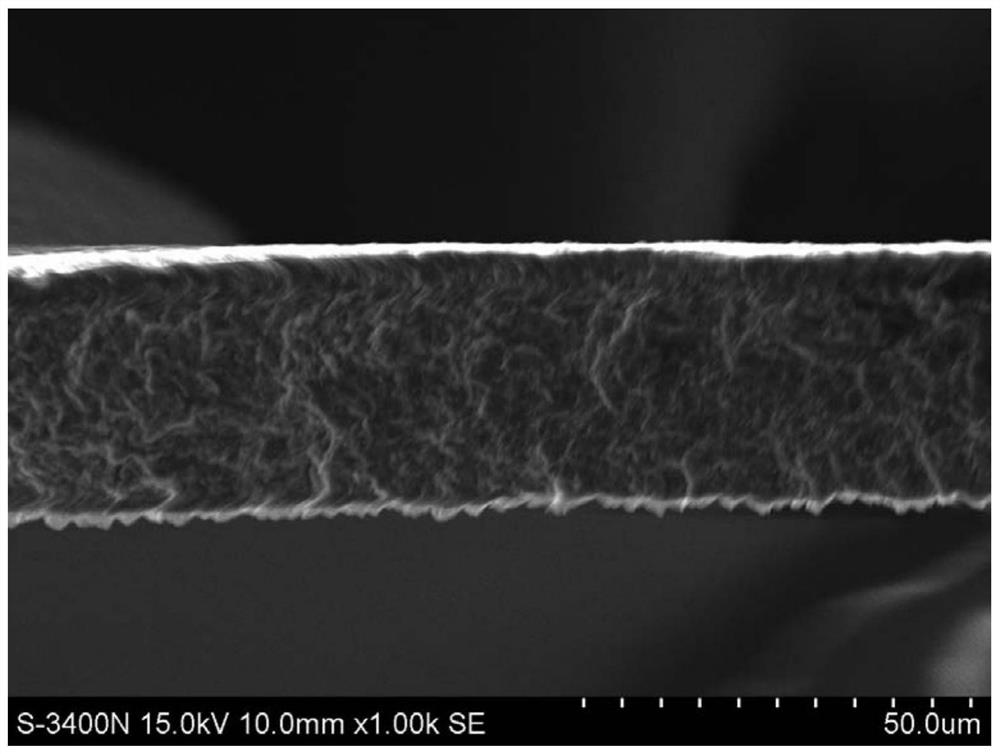

[0054] For the resulting SnO 2 -Cu 2 O nanocomposites were characterized by scanning electron microscopy, and the results were as follows figure 1 shown.

Embodiment 2

[0056] This example is used to prepare SnO 2 -Cu 2 O nanocomposite material, concrete preparation method is as follows:

[0057] 1) 0.04mol CuCl 2 , 0.004mol SnCl 2 2H 2 0 and 0.4 mL of 30 mol / L hydrochloric acid were added to 200 mL of deionized water, and ultrasonically treated for 15 min to obtain a mixed solution;

[0058] 2) Add ammonia water to the mixed solution until the solution pH=9.0, then add 0.4mL hydrazine hydrate, and carry out the reduction reaction at room temperature for 1 hour;

[0059] 3) The obtained product was washed with ethanol, dried in vacuum at 40°C, and then the dry powder was calcined at 100°C for 1 h under the protection of argon to obtain SnO 2 -Cu 2 O nanocomposites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com