EPS foam-epoxy resin composite die and preparation method thereof

A technology of epoxy resin and composite mold, applied in the direction of epoxy resin glue, manufacturing tools, adhesive types, etc., can solve the problems of easy deformation of the mold, difficulty in mold release, etc., to solve the problems of easy deformation, excellent porosity, excellent The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

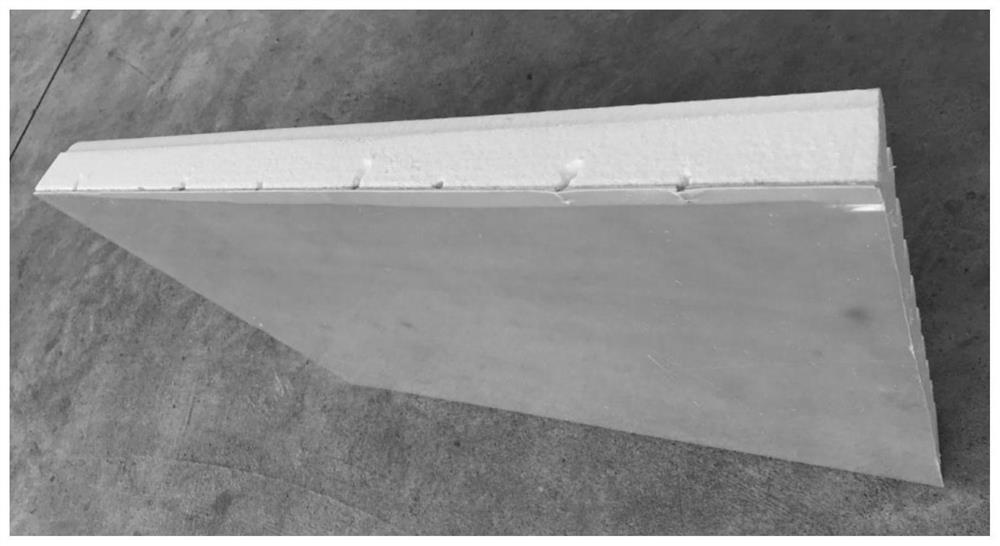

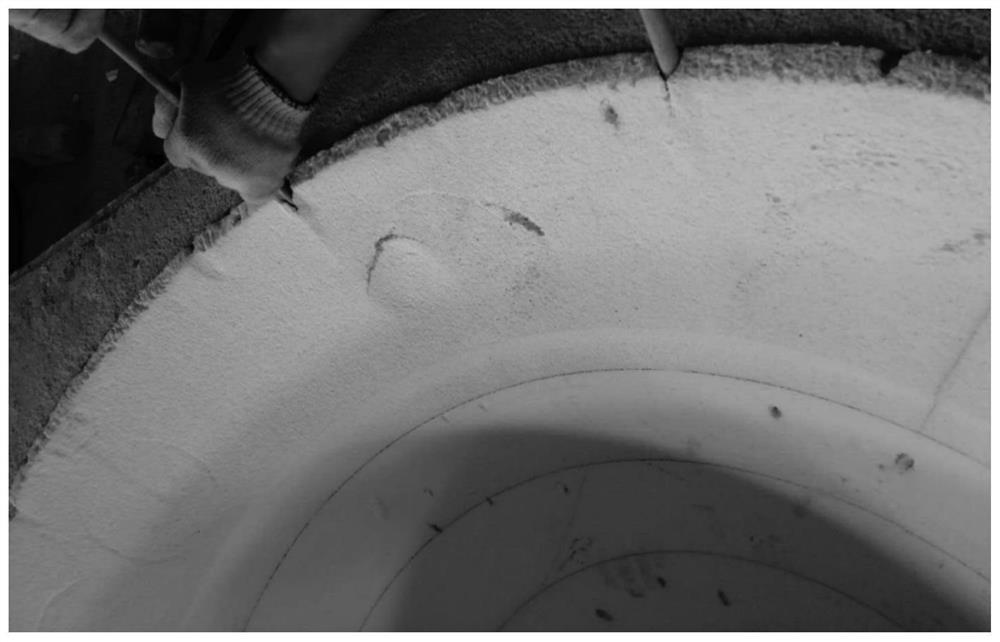

[0040] A kind of EPS foam-epoxy resin compound mould, is that the epoxy resin reinforcing plate that thickness is 1mm is pasted on the molding surface of EPS foam mould, and composite forms, and described epoxy resin reinforcing plate comprises following raw material: Bisphenol F epoxy resin 3kg, bisphenol A epoxy resin 10kg, E-51 epoxy resin 5kg, isophthalic unsaturated polyester resin 10kg, rush fiber powder 1kg, chitosan 1kg, oxalic acid 1kg, 0.5kg of wheat straw powder, 0.01kg of triphenylphosphine, 10kg of dimethyl sulfoxide, 5kg of stone powder, and 5kg of curing agent; the stone powder includes the following raw materials: 3kg of quartz powder, 1kg of aluminum hydroxide powder , marble powder 0.5kg; described curing agent comprises the following raw materials of weight: trimellitic anhydride 1kg, methyltetrahydrophthalic anhydride 1kg, N-(3,4-dichlorophenyl)-N', N'-dimethylurea 2kg.

[0041] The preparation method of described epoxy resin reinforced board comprises the...

Embodiment 2

[0055] A kind of EPS foam-epoxy resin compound mould, is that the epoxy resin reinforcement plate that thickness is 3mm is pasted on the mold surface of EPS foam mould, and composite forms, and described epoxy resin reinforcement plate comprises following raw material: Bisphenol F epoxy resin 5kg, bisphenol A epoxy resin 15kg, E-51 epoxy resin 8kg, isophthalic unsaturated polyester resin 12kg, rush fiber powder 3kg, chitosan 2kg, oxalic acid 2kg, wheat straw powder 1kg, triphenylphosphine 0.03kg, dimethyl sulfoxide 15kg, stone powder 7kg, curing agent 8kg; the stone powder includes the following raw materials by weight: quartz powder 3.5kg, aluminum hydroxide powder 1.5 kg, marble powder 1kg; the curing agent includes the following raw materials: trimellitic anhydride 2kg, methyltetrahydrophthalic anhydride 2kg, N-(3,4-dichlorophenyl)-N',N'-dimethylurea 3.5kg.

[0056] The preparation method of described epoxy resin reinforced board comprises the following steps:

[0057] a....

Embodiment 3

[0070] A kind of EPS foam-epoxy resin compound mould, is that the epoxy resin reinforcing plate that is 5mm in thickness is pasted on the profile surface of EPS foam mould, and composite forms, and described epoxy resin reinforcing plate is by comprising following raw material: Bisphenol F epoxy resin 8kg, bisphenol A epoxy resin 20kg, E-51 epoxy resin 10kg, isophthalic unsaturated polyester resin 15kg, rush fiber powder 5kg, chitosan 3kg, oxalic acid 3kg, 1.4kg of wheat straw powder, 0.05kg of triphenylphosphine, 20kg of dimethyl sulfoxide, 10kg of stone powder, and 10kg of curing agent; the stone powder includes the following raw materials: 4kg of quartz powder, 2kg of aluminum hydroxide powder , marble powder 1.5kg; described solidifying agent comprises the raw material of following weight: trimellitic anhydride 3kg, methyltetrahydrophthalic anhydride 3kg, N-(3,4-dichlorophenyl)-N', N'-dimethylurea 5kg.

[0071] The preparation method of described epoxy resin reinforced bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com