Modified SBA-15 molecular sieve material and preparation method thereof, and isobutane dehydrogenation catalyst and preparation method and application thereof

A technology for dehydrogenation catalysts and molecular sieves, which is applied in molecular sieve catalysts, physical/chemical process catalysts, hydrocarbons, etc., and can solve problems such as easy carbon deposition, low conversion rate, and high catalyst preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

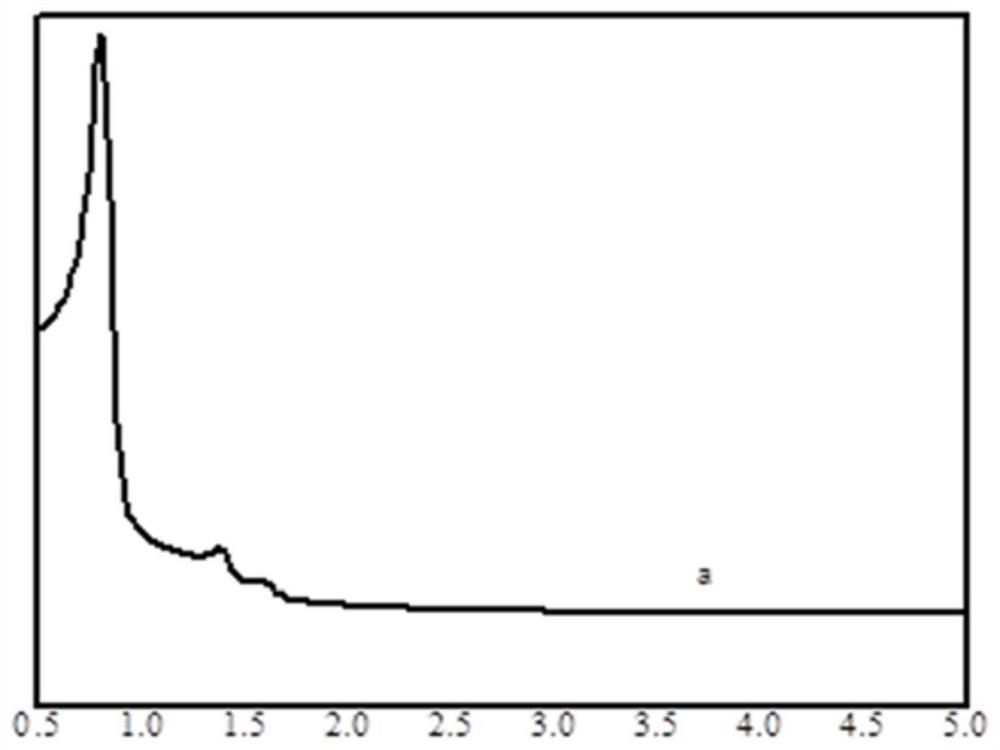

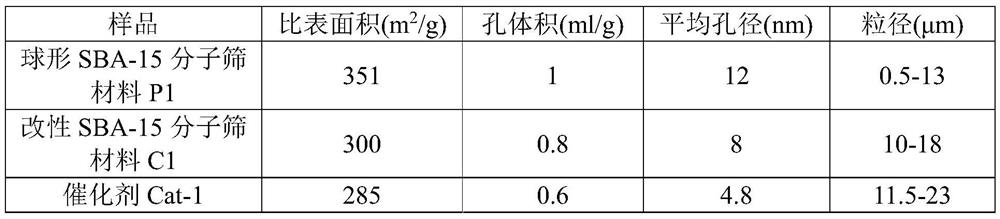

[0039]According to a preferred embodiment of the present invention, the method for preparing the modified SBA-15 molecular sieve material includes: in the presence of an inert gas, in a reactor equipped with stirring, add the organic solvent tetrahydrofuran, and control the temperature of the reactor to 25-40°C, quickly add magnesium chloride and titanium tetrachloride when the stirring is turned on, adjust the system temperature to 60-75°C and react at a constant temperature for 1-5 hours, until the magnesium chloride and titanium tetrachloride are completely dissolved, and the mixture containing magnesium chloride and tetrachloride is obtained. Organic solution of titanium oxide. The organic solution containing magnesium chloride and titanium tetrachloride as mentioned above is mixed and contacted with SBA-15 molecular sieve, and the ratio between the components is controlled so that, relative to 1mol of titanium, the content of magnesium is 5-18mol, tetrahydrofuran 20-200mo...

Embodiment 1

[0068] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

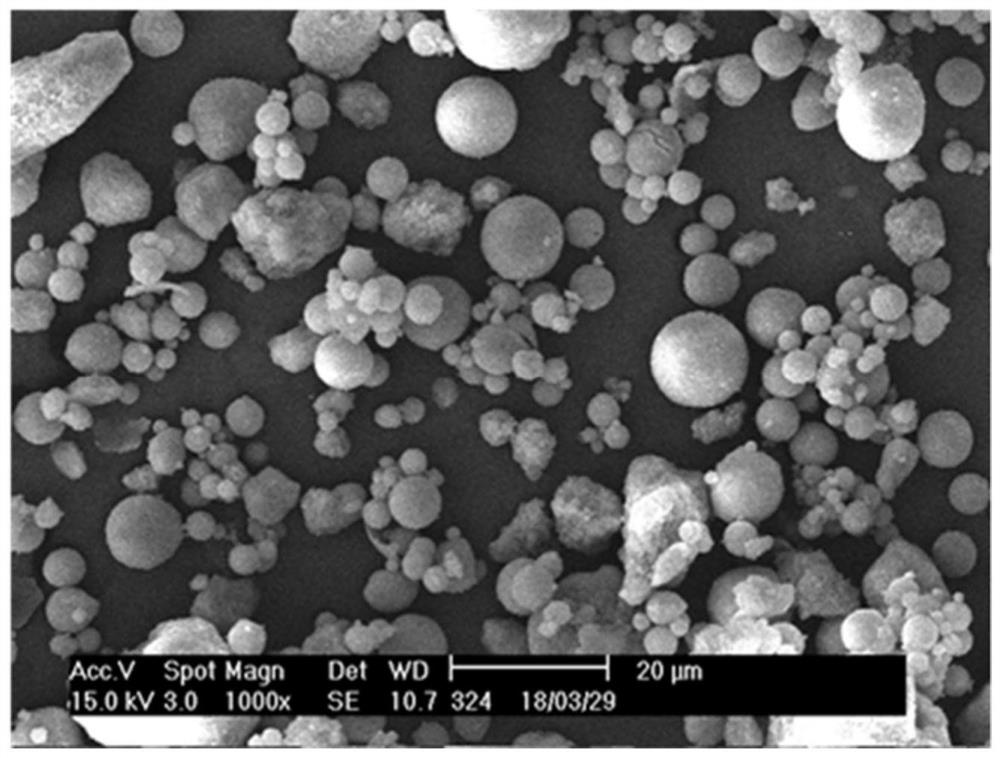

[0069] (1) Preparation of SBA-15 molecular sieve

[0070] The three-block copolymer polyethylene oxide-polyoxypropylene-polyoxyethylene is added to the hydrochloric acid aqueous solution, and the molar feed ratio is three-block copolymer polyethylene oxide-polyoxypropylene-polyoxyethylene: water: hydrogen chloride = 1 : 10157: 243, stirred at 40°C until dissolved to obtain a mixed solution; then added tetraethyl orthosilicate to it, according to molar feed ratio, triblock copolymer polyethylene oxide-polyoxypropylene-polyoxyethylene: Ethyl orthosilicate = 1:60, stirred at 40°C for 24h, then transferred the resulting solution to a polytetrafluoroethylene-lined reactor, crystallized at 160°C for 20h, then filtered and deionized Washing with water for 4 times, drying at 120°C for 5 hours after suction filtration, to obtain the raw powder of mesoporous material; washing ...

Embodiment 2

[0084] This example is used to illustrate the isobutane dehydrogenation catalyst and its preparation method.

[0085] (1) Preparation of SBA-15 molecular sieve

[0086] The three-block copolymer polyethylene oxide-polyoxypropylene-polyoxyethylene is added to the hydrochloric acid aqueous solution, and the molar feed ratio is three-block copolymer polyethylene oxide-polyoxypropylene-polyoxyethylene: water: hydrogen chloride = 1 : 10000: 250, stirred at 50°C until dissolved to obtain a mixed solution; then added tetraethyl orthosilicate to it, according to molar feed ratio, triblock copolymer polyethylene oxide-polyoxypropylene-polyoxyethylene: Ethyl orthosilicate = 1:70, stirred at 50°C for 15h, then transferred the resulting solution to a polytetrafluoroethylene-lined reactor, crystallized at 155°C for 22h, then filtered and deionized Washing with water for 5 times, drying at 110°C for 6 hours after suction filtration, to obtain the original powder of mesoporous material; was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com