Preparation method of nanguo pear brandy through low-temperature aroma-recovering

A technology of brandy and fruit pears, which is applied in the field of wine making, can solve the problems of decomposition loss of aromatic components and precursor substances, the inability to realize the volatile aroma of Nanguo pears, unfavorable nutrition and volatile flavor components, etc., so as to enrich product varieties and increase product additions. Value and economic benefits, the effect of uniform and stable fermentation broth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

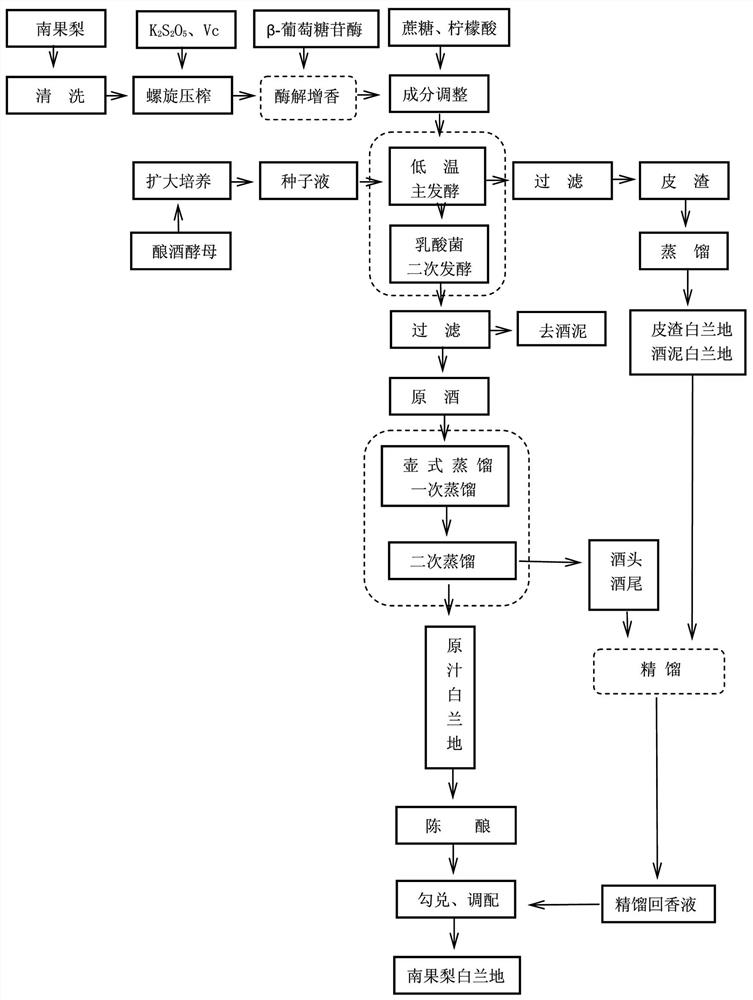

Image

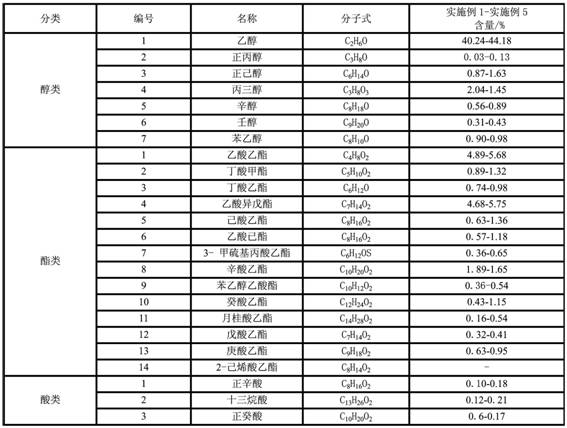

Examples

Embodiment 1

[0032]The preparation method of Nanguo pear brandy low-temperature back fragrance of the present embodiment, its production steps are as follows:

[0033] The preparation method of Nanguo pear brandy with low-temperature back fragrance, the steps are as follows:

[0034] Raw material processing: Naturally ripe and non-rotten Nanguo pears are naturally post-ripened at room temperature for 5 days, and then rinsed with water in a fruit washing machine for 3 minutes to remove surface dust, and after natural drying, use a screw press Squeeze and crush the fruit of Nanguo pear into a pulp containing pulp. The pulp accounts for 50% of the total mass of the pulp, and the integrity rate of the fruit seeds is ≥95%. At the same time, add color protection solution to prevent the pulp from oxidative browning and color protection. The specific ingredients and mass fraction added to the liquid are 50ppm potassium metabisulfite and 200ppm Vc, and β-glucosidase with a mass fraction of 50ppm is...

Embodiment 2

[0041] The preparation method of Nanguo pear brandy low-temperature back fragrance of the present embodiment, its production steps are as follows:

[0042] The preparation method of Nanguo pear brandy with low-temperature back fragrance, the steps are as follows:

[0043] Raw material processing: Naturally mature and non-rotten Nanguo pears are naturally post-ripened at room temperature for 7 days, and then rinsed with water bubbles in a fruit washing machine to remove surface dust, dried by an air dryer, and then used a screw press Squeeze and crush the fruit of Nanguo pear into a pulp containing pulp. The pulp accounts for 70% of the total mass of the pulp, and the integrity rate of the fruit seeds is ≥ 95%. At the same time, color protection solution is added to prevent the pulp from oxidative browning and color protection. The specific ingredients and dosage of the solution are 100ppm potassium metabisulfite and 50ppm Vc, and the beta-glucosidase with a mass fraction of 75...

Embodiment 3

[0050] The preparation method of Nanguo pear brandy low-temperature back fragrance of the present embodiment, its production steps are as follows:

[0051] The preparation method of Nanguo pear brandy with low-temperature back fragrance, the steps are as follows:

[0052] Raw material processing: Naturally ripe and non-rotten Nanguo pears are naturally post-ripened at room temperature for 6 days, and then rinsed with water bubbles in a fruit washing machine to remove surface dust, dried naturally, and squeezed by a screw press Crushing, crushing the fruit of Nanguo pear into pulp containing pulp, pulp accounts for 60% of the total mass of pulp, and the integrity rate of fruit seeds is ≥ 95%, adding color protection solution to prevent oxidative browning of pulp while crushing, color protection liquid The specific added ingredients and dosage are 75ppm potassium metabisulfite and 100ppm Vc, adding β-glucosidase with a mass fraction of 100ppm to the fruit pulp, and aromatizing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com