Rhodosporidium paludigenum and application thereof in producing beta-carotene by taking straws as raw materials

A technology of marine red yeast and carotene, applied in microorganism-based methods, fermentation, microorganisms, etc., can solve the problems of high requirements on lighting and nutrient conditions, difficult to use dissolved oxygen, and high viscosity of fermentation broth, and achieve high efficiency and high quality. The effect of easy control of production and fermentation and fast growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Preparation of fiber hydrolyzate:

[0045] 1) The raw material of wheat straw was washed and chopped, and the wheat straw was pretreated by steam explosion. The conditions of steam explosion were as follows: the temperature of saturated steam was 230°C, the pressure was 0.2 Mpa, and the holding time was 2 min;

[0046] 2) The steam-exploded wheat straw is then treated with sodium hydroxide and sodium sulfite, the weight of sodium hydroxide: dry weight of wheat straw raw material is 1:4, the weight ratio of sodium sulfite: sodium hydroxide is 1:5, and the treatment conditions are: The reaction temperature was 150 °C and the time was 1 h. After fully removing the lignin, extract the wheat straw fiber, dehydrate and fully wash away the residual lye;

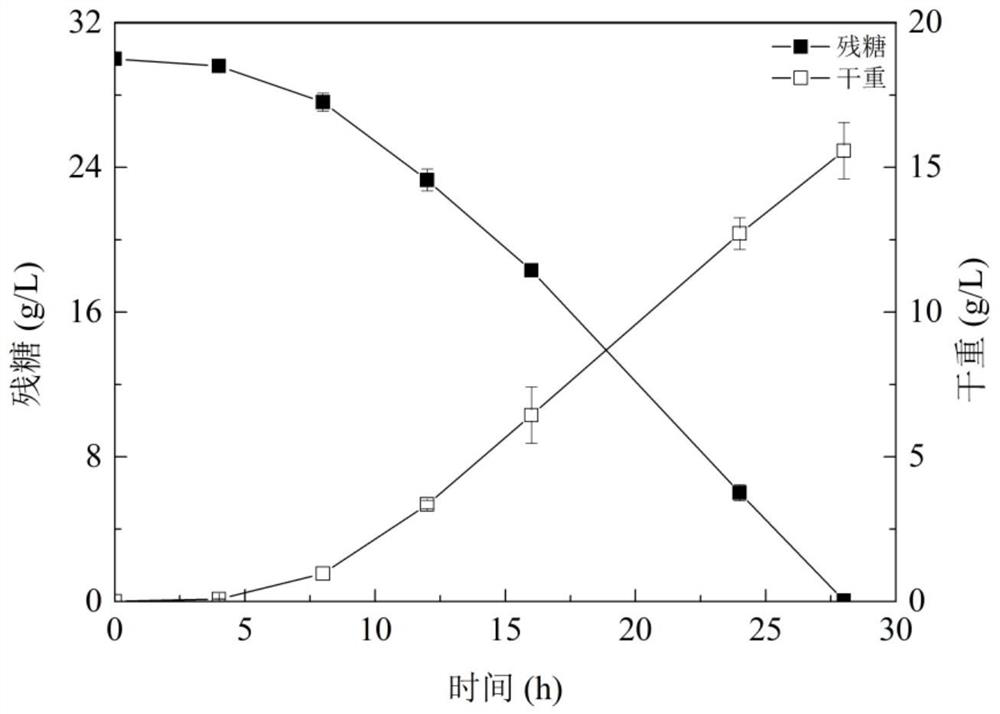

[0047] 3) Soak straw fibers in acetic acid-sodium acetate (or similar buffer pair with buffering effect) buffer solution, add cellulase, and hydrolyze the fiber slurry into a high-concentration sugar solution; the hydrol...

Embodiment 2

[0055] (1) Preparation of fiber hydrolyzate:

[0056] 1) The raw material of rice straw was washed and chopped, and the rice straw was pretreated by steam explosion. The conditions of steam explosion were as follows: the temperature of saturated steam was 210°C, the pressure was 1.2 Mpa, and the holding time was 8 minutes;

[0057] 2) The steam-exploded wheat straw is then treated with sodium hydroxide and sodium sulfite, the weight of sodium hydroxide: the absolute dry weight of rice straw raw material is 1:6, the weight ratio of sodium sulfite: sodium hydroxide is 1:3, and the treatment conditions are: The reaction temperature was 160 °C and the time was 1 h. After fully removing the lignin, extract the wheat straw fiber, dehydrate and fully wash away the residual lye;

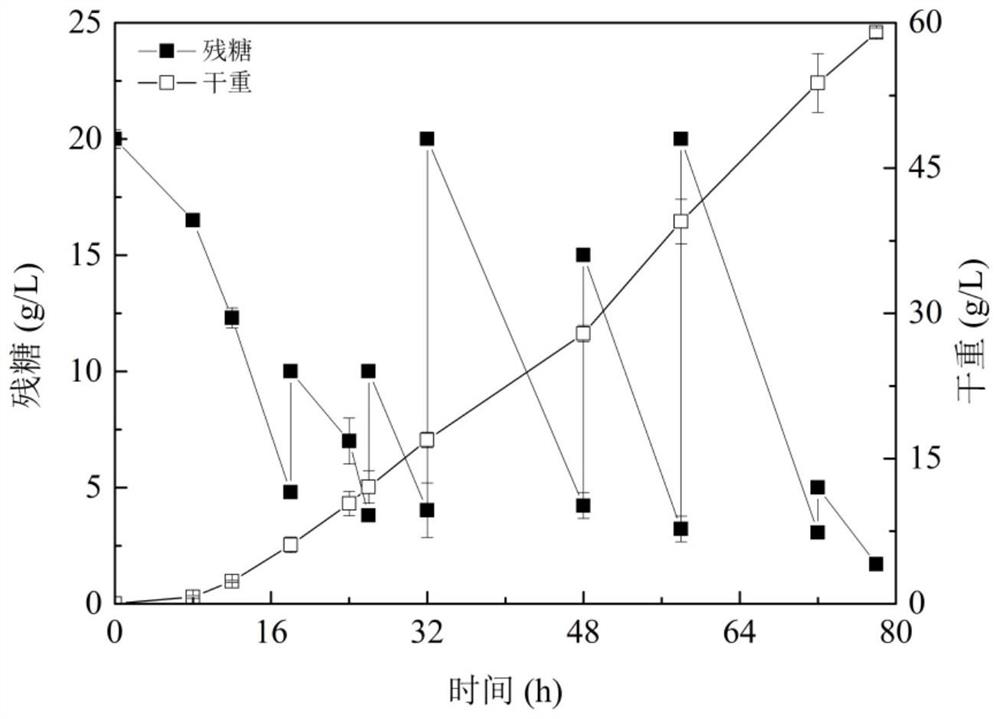

[0058] 3) Soak straw fibers in acetic acid-sodium acetate (or similar buffer pair with buffering effect) buffer solution, add cellulase, and hydrolyze the fiber slurry into a high-concentration sugar soluti...

Embodiment 3

[0069] (1) Preparation of fiber hydrolyzate:

[0070] 1) The corn stalks were washed and chopped, and the corn stalks were pretreated by steam explosion. The steam explosion conditions were as follows: the saturated steam temperature was 250 °C, the pressure was 0.6 Mpa, and the holding time was 5 min;

[0071] 2) The steam-exploded corn stalks are then treated with sodium hydroxide and sodium sulfite. The weight of sodium hydroxide: the absolute dry weight of corn stalks is 1:5, and the weight ratio of sodium sulfite: sodium hydroxide is 1:5. The treatment conditions are: The reaction temperature was 150 °C and the time was 2 h. After fully removing the lignin, extract the corn stalk fiber, dehydrate and fully wash away the residual lye;

[0072] 3) Soak straw fiber in acetic acid-sodium acetate (or similar buffer pair with buffering effect) buffer solution, add cellulase, and hydrolyze the fiber slurry into a high-concentration sugar solution; the hydrolysis conditions are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tolerance concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com