Preparation method of calcium hydroxytitanate fiber coating on the surface of titanium-based implant with complex morphology

A technology of calcium hydroxy titanate and implants, applied in coatings, metal material coating processes, pharmaceutical formulations, etc., can solve the problems of lack of biological activity, long healing time, and low bonding strength, and achieve simple ingredients and low production costs The effect of low and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A method for preparing a calcium hydroxytitanate fiber coating on the surface of a titanium-based implant with a complex shape, comprising the following steps:

[0046] 1) Mechanical polishing

[0047] Using pure titanium sheet as the base material, the surface of the metal sample is polished and smooth with 100#, 400#, 800#, 1500# metallographic sandpaper in sequence, and then ultrasonically cleaned with acetone, absolute ethanol and deionized water for 10~ 20min, dry for later use.

[0048] 2) Etching

[0049] Prepare the etching solution, the ratio is, the volume ratio of nitric acid solution: hydrofluoric acid solution: deionized water is 1:1:8, the mass fraction of the nitric acid solution is 69.2%, and the mass fraction of the hydrofluoric acid solution is 40% %, put the mechanically polished titanium sheet into the etching solution to etch for 20-30s, wash it three times with deionized water, and ultrasonically clean it with deionized water for 20-30s, and dry ...

Embodiment 1

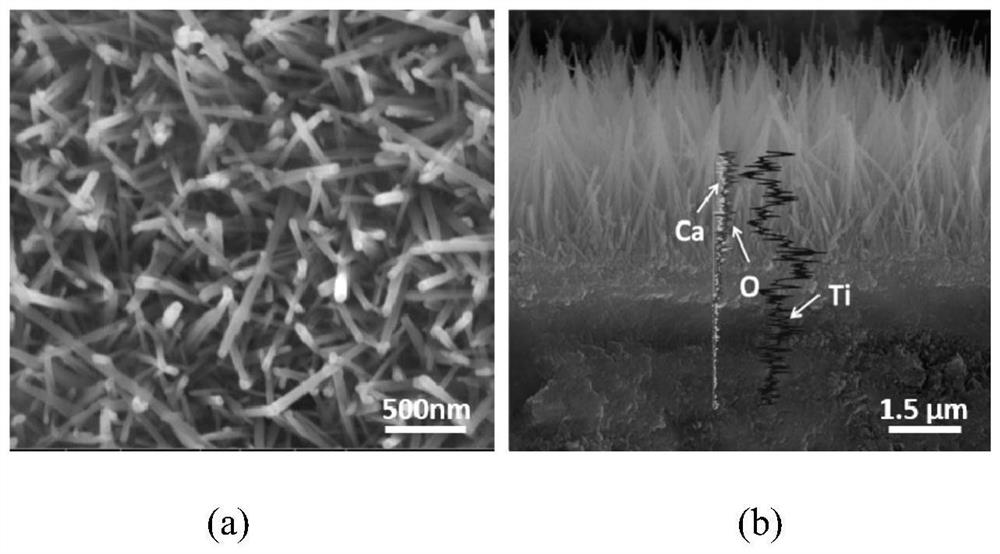

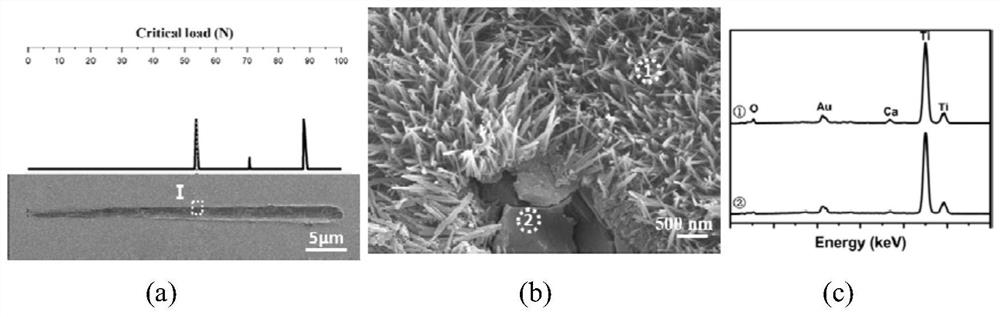

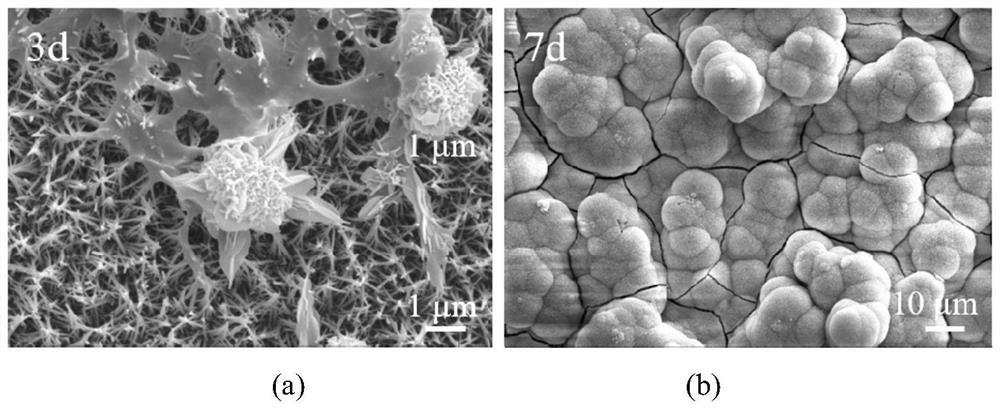

[0058] First, the titanium sheet is mechanically polished, and the surface of the titanium sheet is polished and smooth with 100#, 400#, 800#, and 1500# metallographic sandpaper in sequence, and then ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 20 minutes, and dried Ready to use, the surface morphology of the titanium sheet is as follows Figure 12 (a) shown. The mechanically polished titanium sheet was etched in the etching solution for 30s, washed three times with deionized water, and ultrasonically cleaned with deionized water for 30s, and dried for use. The surface appearance of the titanium sheet was as follows: Figure 12 (b) shown. Set the concentration to 1.0mol·L -1 The NaOH solution was injected into the hydrothermal reaction kettle, and the filling degree of the solution was 33%, and the pure titanium sample treated according to the above process was soaked in the solution, and it was hydrothermally treated at 220°C for 2 hours, a...

Embodiment 2

[0060] First, the titanium sheet is mechanically polished, and the surface of the titanium sheet is polished and smooth with 100#, 400#, 800#, and 1500# metallographic sandpaper in sequence, and then ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 15 minutes, and then dried stand-by. The mechanically polished titanium sheet was etched in an etching solution for 25 s, washed three times with deionized water, ultrasonically cleaned with deionized water for 25 s, and dried for use. Set the concentration to 1.0mol·L -1 The NaOH solution was injected into the hydrothermal reaction kettle, and the filling degree of the solution was 33%, and the pure titanium sample treated according to the above process was soaked in the solution, and it was hydrothermally treated at 220°C for 5 hours, and the sample was taken out and Rinse with deionized water and dry for use, and complete a hydrothermal treatment process; the concentration is 0.5mol L -1 CaCl 2 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com