Preparation process of surface scatter type high-wear-resistance ceramic material

A ceramic material and a preparation process technology, which is applied in the field of preparation of surface scattered high wear-resistant ceramic materials, can solve the problems of decreased service life, need to be improved, and new materials play a major role, and achieve the effect of avoiding falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

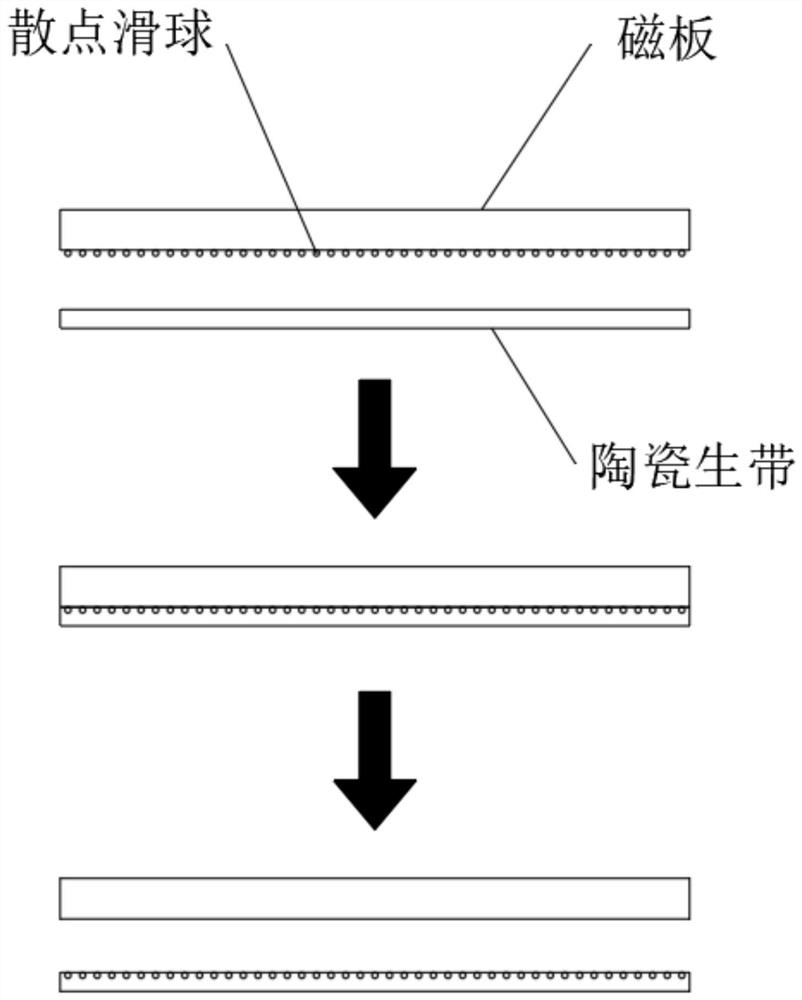

[0045] see figure 1 , a preparation process of a surface-scattered high-wear-resistant ceramic material, comprising the following steps:

[0046] S1. Weigh 10 parts of calcined talc, 10 parts of magnesium oxide, 10 parts of silicon dioxide, 12 parts of aluminum oxide, 10 parts of silicon nitride, 5 parts of silicon boride, 10 parts of metal chromium powder, and 15 parts of zirconium dioxide according to the proportion , 5 parts of polyvinyl butyral and 10 parts of polypropylene resin are uniformly mixed and ball milled to obtain ceramic powder;

[0047] S2. Weigh 10 parts of water, 10 parts of binder, 2 parts of plasticizer and 1 part of dispersant and mix them uniformly with ceramic powder to obtain ceramic slurry;

[0048] S3. After the ceramic slurry is subjected to vacuum defoaming treatment, it is tape cast on a tape casting machine and heated and dried until it is semi-cured;

[0049] S4. Pre-process a matching magnetic plate, and absorb a number of evenly distributed ...

Embodiment 2

[0061] see figure 1 , a preparation process of a surface-scattered high-wear-resistant ceramic material, comprising the following steps:

[0062] S1. Weigh 12 parts of calcined talc, 11 parts of magnesium oxide, 15 parts of silicon dioxide, 13 parts of aluminum oxide, 15 parts of silicon nitride, 8 parts of silicon boride, 15 parts of metal chromium powder, and 20 parts of zirconium dioxide according to the proportion , 8 parts of polyvinyl butyral and 18 parts of polypropylene resin are uniformly mixed and ball milled to obtain ceramic powder;

[0063] S2. Weighing 15 parts of water, 15 parts of binder, 3 parts of plasticizer and 2 parts of dispersant and uniformly mixing with ceramic powder to obtain ceramic slurry;

[0064] S3. After the ceramic slurry is subjected to vacuum defoaming treatment, it is tape cast on a tape casting machine and heated and dried until it is semi-cured;

[0065] S4. Pre-process a matching magnetic plate, and absorb a number of evenly distribute...

Embodiment 3

[0070] see figure 1 , a preparation process of a surface-scattered high-wear-resistant ceramic material, comprising the following steps:

[0071] S1. Weigh 15 parts of burnt talc, 12 parts of magnesium oxide, 20 parts of silicon dioxide, 15 parts of aluminum oxide, 20 parts of silicon nitride, 10 parts of silicon boride, 20 parts of metal chromium powder, and 25 parts of zirconium dioxide according to the proportion 10 parts of polyvinyl butyral and 25 parts of polypropylene resin are uniformly mixed and ball milled to obtain ceramic powder;

[0072] S2. Weighing 20 parts of water, 20 parts of binder, 5 parts of plasticizer and 3 parts of dispersant and uniformly mixing with ceramic powder to obtain ceramic slurry;

[0073] S3. After the ceramic slurry is subjected to vacuum defoaming treatment, it is tape cast on a tape casting machine and heated and dried until it is semi-cured;

[0074] S4. Pre-process a matching magnetic plate, and absorb a number of evenly distributed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com