Mildew-proof antibacterial ultrathin density board and preparation method thereof

A technology of anti-mildew and anti-bacterial and anti-mold and anti-bacterial agent, which is applied in the field of anti-mildew and anti-bacterial ultra-thin density board and its preparation, can solve the problems of affecting the appearance and strength of density board, shortening the service life of density board, and the cost of molding, so as to achieve improvement Bactericidal ability, enhanced bonding, and strength-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

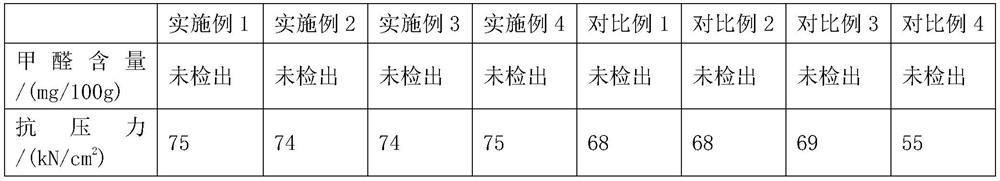

Examples

Embodiment 1

[0037] A mildew-proof and antibacterial ultra-thin density board, the raw materials include the following components in parts by mass:

[0038] 50 parts of wood fiber, 30 parts of phenolic resin, 1.1 parts of γ-(2,3-glycidoxy)propyltrimethoxysilane, 20 parts of polyurethane emulsion, 4.5 parts of sodium methyl silicate and 3.5 parts of anti-mold and antibacterial agent ;

[0039] Wherein, the antifungal and antibacterial agent is a mixture of dodecyldimethylbenzyl ammonium chloride, peppermint oil, nano-titanium dioxide and 2,4-dihydroxybenzophenone in a mass ratio of 3:1:1:1.

[0040] Preparation of mildew and antibacterial ultra-thin density board:

[0041] (1) mixing dodecyl dimethyl benzyl ammonium chloride, peppermint oil, nano-titanium dioxide and 2,4-dihydroxybenzophenone evenly according to the mass ratio to obtain an anti-mildew and antibacterial agent;

[0042] (2) Pulverize the wood fiber, soak it in acetic acid solution for 5 hours, freeze-dry the wood fiber at -...

Embodiment 2

[0047] A mildew-proof and antibacterial ultra-thin density board, the raw materials include the following components in parts by mass:

[0048] 60 parts of wood fiber, 250 parts of phenolic resin, 1 part of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 22 parts of polyurethane emulsion, 3.8 parts of sodium methyl silicate and 4.2 parts of anti-mold and antibacterial agent ;

[0049] Wherein, the antifungal and antibacterial agent is a mixture of dodecyldimethylbenzyl ammonium chloride, peppermint oil, nano-titanium dioxide and 2,4-dihydroxybenzophenone in a mass ratio of 4:2:1.2:1.

[0050] Preparation of mildew and antibacterial ultra-thin density board:

[0051] (1) mixing dodecyl dimethyl benzyl ammonium chloride, peppermint oil, nano-titanium dioxide and 2,4-dihydroxybenzophenone evenly according to the mass ratio to obtain an anti-mildew and antibacterial agent;

[0052] (2) Pulverize the wood fiber and soak it in acetic acid solution for 6 hours. After soaking, freeze-dr...

Embodiment 3

[0057] A mildew-proof and antibacterial ultra-thin density board, the raw materials include the following components in parts by mass:

[0058] 55 parts of wood fiber, 28 parts of phenolic resin, 1.2 parts of γ-(2,3-glycidoxy)propyltrimethoxysilane, 13 parts of polyurethane emulsion, 4 parts of sodium methyl silicate and 3.8 parts of anti-mold and antibacterial agent ;

[0059] Wherein, the antifungal and antibacterial agent is a mixture of dodecyldimethylbenzyl ammonium chloride, peppermint oil, nanometer titanium dioxide and 2,4-dihydroxybenzophenone in a mass ratio of 5:2:1.1:1.

[0060] Preparation of mildew and antibacterial ultra-thin density board:

[0061] (1) mixing dodecyl dimethyl benzyl ammonium chloride, peppermint oil, nano-titanium dioxide and 2,4-dihydroxybenzophenone evenly according to the mass ratio to obtain an anti-mildew and antibacterial agent;

[0062] (2) Pulverize the wood fibers, soak them in acetic acid solution for 5 hours, freeze-dry the wood fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com