Preparation method of m-cresol

A cresol and methyl technology, applied in the preparation of organic compounds, the preparation of carbon-based compounds, chemical instruments and methods, etc., can solve the problems of difficult separation and purification of products, harsh reaction conditions, etc., and achieve novel synthetic routes, simple operation, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

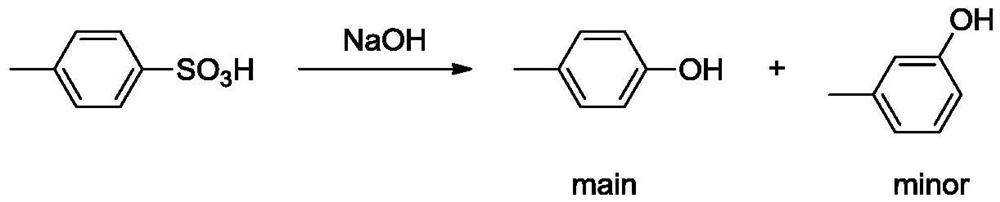

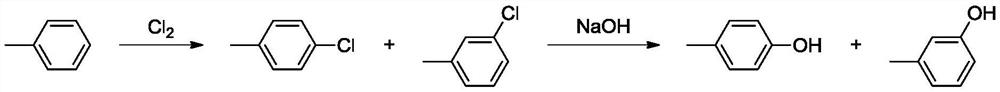

Problems solved by technology

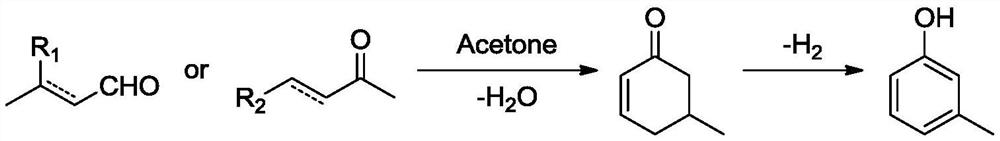

Method used

Image

Examples

Embodiment 1

[0039] Synthesis of 5-Methyl-2-Cyclohexenone by Gas Phase Condensation of Crotonaldehyde and Acetone

[0040] The gas-phase condensation reaction is carried out in a tubular reactor. The length of the reaction tube is 60 cm, and the inner diameter is 2.3 cm. The middle part of the reaction tube is filled with a spherical zinc oxide catalyst (100 g, with a purity of 95%), and the top and bottom ends are filled with ceramic ring fillers. When conducting condensation experiments, first turn on the power of the fixed bed reactor, open the inlet and outlet valves of the reaction tube carrier gas, and turn on the nitrogen carrier gas at a flow rate of 100mL / min, and the carrier gas goes in and out of the reaction tube. Turn on the heating mantle of the reaction tube to raise the temperature of the reaction tube to 260°C; turn on the heat tracing of the preheating tank on the feed line to raise its temperature to 220°C. After the temperature of the preheating tank and the reaction tu...

Embodiment 2

[0043] Synthesis of 5-Methyl-2-Cyclohexenone by Vapor Phase Condensation of 3-Hydroxybutyraldehyde and Acetone

[0044] The gas-phase condensation reaction is carried out in a tubular reactor. The length of the reaction tube is 60 cm, and the inner diameter is 2.3 cm. The middle part of the reaction tube is filled with a spherical zinc oxide catalyst (100 g, with a purity of 95%), and the top and bottom ends are filled with ceramic ring fillers. When conducting condensation experiments, first turn on the power of the fixed-bed reactor, open the inlet and outlet valves of the reaction tube carrier gas, and turn on the nitrogen carrier gas at a flow rate of 35mL / min. The carrier gas goes in and out of the reaction tube. Turn on the heating mantle of the reaction tube to raise the temperature of the reaction tube to 270°C; turn on the heat tracing of the preheating tank on the feed line to raise its temperature to 220°C. After the temperature of the preheating tank and the reacti...

Embodiment 3

[0046] Synthesis of 5-Methyl-2-Cyclohexenone by Vapor Phase Condensation of 3-Methoxybutyraldehyde and Acetone

[0047] First configure the raw material solution, 3-methoxybutyraldehyde (143.0g, 1.4mol), acetone (813.1g, 14.0mol) and trimethyl phosphate (0.2g, 0.0014mol), the appearance is a colorless transparent solution . Start the power supply of the fixed bed device, feed nitrogen carrier gas at 120mL / min, and the carrier gas goes in and out of the reaction tube; turn on the preheating tank and the reaction tube to heat, and raise the temperature to 220°C and 280°C respectively. After the temperature of the preheating tank and the reaction tube is stable for 0.5h, start the feed pump to feed the raw material liquid, the feed rate is 1.0g / min, and the weight hourly space velocity is 0.6h -1 . The reaction tube has a length of 60 cm and an inner diameter of 2.3 cm. The middle part of the reaction tube is filled with a spherical barium oxide catalyst (100 g, with a purity o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com