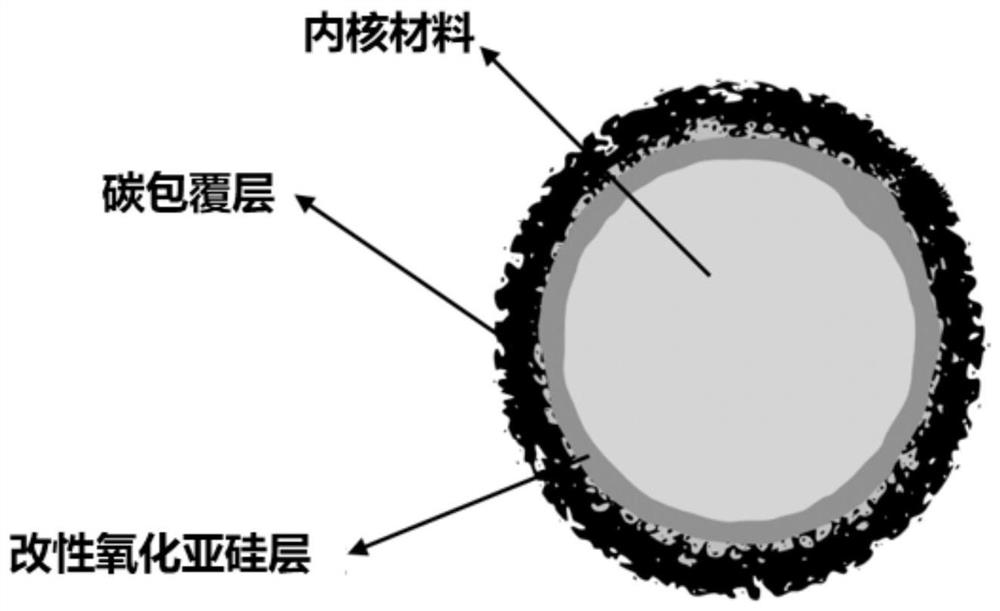

Lithium ion battery negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, which is applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problem of not being able to effectively utilize the advantages of the composite of negative electrode materials and silicon oxide materials, high-capacity negative electrode materials volume expansion batteries, Particles are easy to pulverize and break, and achieve the effects of industrialized large-scale production, simple and efficient preparation methods, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Step (1) According to the mass ratio of silicon oxide and flake graphite at 0.1:1, take 1 kg of silicon oxide and 10 kg of flake graphite and add them to the vacuum reaction chamber and the rotary collection chamber respectively. At 200°C, Ar:H 2 The flake graphite was pretreated at 200°C with a volume ratio of 7:3.

[0060] Step (2) heating to 1360° C. under the condition of vacuum degree of 60 Pa, keeping the temperature for 5 hours, and the silicon oxide powder is sublimated under the condition of high temperature and vacuum. At the same time, heat the rotary collection chamber to 800°C and keep it warm. Silicon oxide vapor enters the rotary collection chamber and deposits on the surface of flake graphite.

[0061] In the rotary chamber, at 10L / min, keep 300°C, and pass through ammonia gas for 50min.

[0062] Step (3) After cooling down, nitrogen with a flow rate of 20L / min is introduced into the rotary collection chamber and the temperature is raised to 975°C; th...

Embodiment 2

[0065] According to the same method as in Example 1, the lithium ion battery negative electrode material of the present invention is prepared, the difference is: according to step (1) SiO2 and pretreated phosphorus flake graphite with a mass ratio of 0.2:1, respectively get 2kg oxidation Sub-silicon and 10kg flake graphite were added separately. The thickness of the carbon coating layer is 20nm, and the thickness of the silicon oxide coating layer is 300nm.

Embodiment 3

[0067] According to the same method as in Example 1, the lithium-ion battery negative electrode material of the present invention is prepared, the difference is: after cooling and cooling according to the step (3), nitrogen gas with a flow rate of 20 L / min is introduced into the rotary collection bin and the temperature is raised. to 975°C. Feed acetylene with a flow rate of 10L / min to crack it at high temperature, and coat the material in the rotary collection bin with pyrolytic carbon for 1.5 hours. The thickness of the carbon coating layer is 10 nm, and the thickness of the silicon oxide coating layer is 200 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com