Method for improving high-polymerization-degree epsilon-polylysine in product

A high-degree-of-polymerization, poly-lysine technology, applied in microorganism-based methods, chemical instruments and methods, biochemical equipment and methods, etc., which can solve the problem of surface area differential polarization, reduced agent permeation flux, and reduced membrane flux and other problems, to achieve the effect of no phase change, improved antibacterial activity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of embodiment 1ε-polylysine crude product

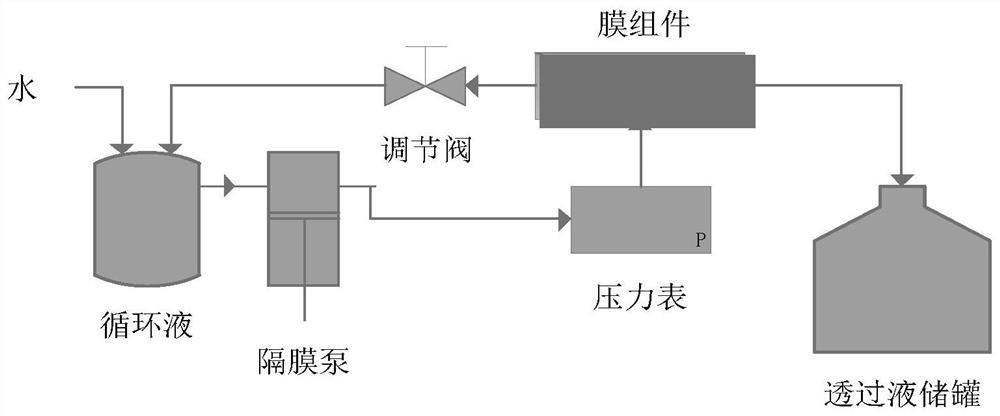

[0042] Using S.albulus M-Z18 as the production strain of polylysine, according to the literature (Pan L, Chen X S, LiuM M, et al. Efficient production ofε-poly-L-lysine from glucose by two-stagefermentation using pH shock strategy [J]. Process Biochemistry, 2017, 63, 8-15.) method for fed-batch fermentation. Ferment to 168h and collect fermented liquid; Get fermented liquid centrifugation (rotating speed 8000rpm, time 30min), remove bacterium and other solid matter; Then carry out adsorption (bed volume 60mL by cation exchange resin D004 (Jiangsu Su Qing Water Treatment Engineering Group Co., Ltd.) , the loading liquid pH 8.5, the loading ε-PL concentration 35g / L, the loading flow rate 1BV / h), remove pigment and foreign protein; then remove salt ions by nanofiltration, using tangential flow nanofiltration system Millipore (USA Millipore Company), the molecular weight cut-off of membrane is 1KDa, and the feed l...

Embodiment 2

[0045] A method for improving high degree of polymerization ε-polylysine in products, comprising the steps of:

[0046] The epsilon-polylysine crude product obtained in Example 1 is prepared into an initial feed liquid of 20g / L, and its pH is controlled to be 6, and the temperature of the feed liquid is 25°C, and a plate membrane (PES membrane) with a molecular weight cut-off of 3000Da is used to carry out Ultrafiltration, the membrane pressure is 0.25MPa. The operation mode is intermittent variable volume diafiltration. Specifically, when the feed liquid is concentrated to 2 / 5 of the volume of the feed liquid, add water to the original volume, and so on until the high degree of polymerization ε-PL no longer appears in the permeate; Obtain ε-polylysine product.

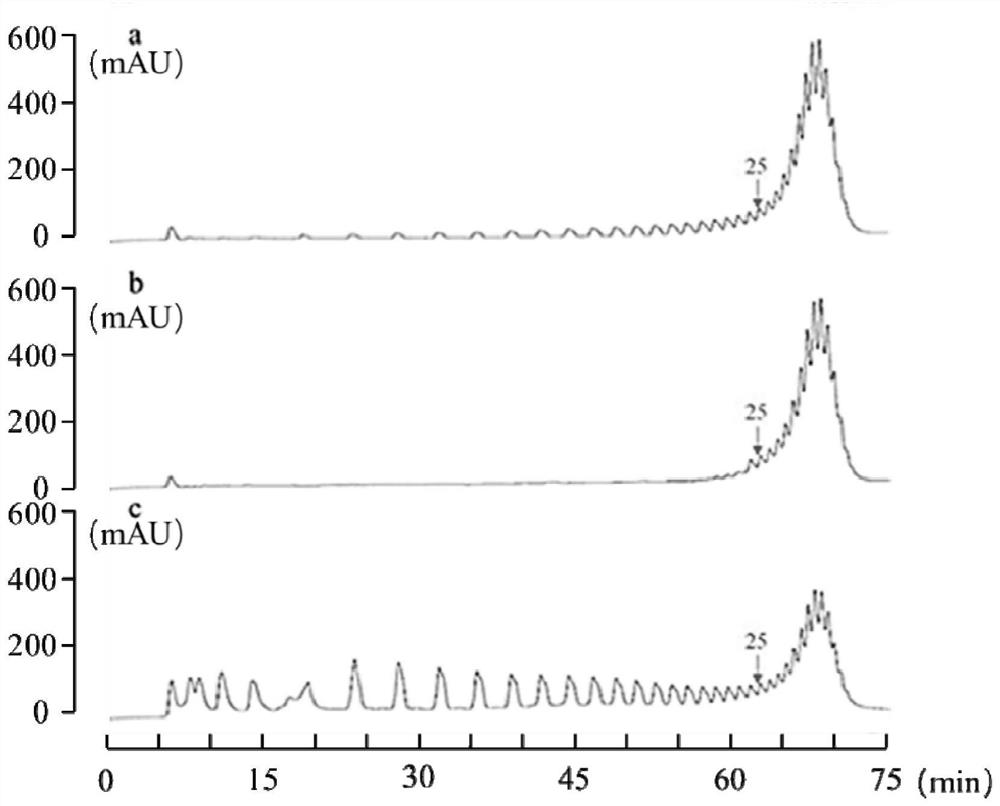

[0047] The retentate and permeate chromatograms are as figure 2 As shown, the retentate and permeate are collected and concentrated to control the concentration at about 10g / L. from figure 2 It can be seen that ...

Embodiment 3

[0049] Adjust the molecular weight of the plate membrane as shown in Table 1, prepare the ε-polylysine crude product obtained in Example 1 into an initial feed liquid of 10 g / L, control its pH to 9, and conduct ultrafiltration at a feed liquid temperature of 25°C , the pressure across the membrane is 0.25MPa; when the feed liquid is concentrated to 2 / 5 of the volume of the raw material liquid, that is, the volume of the intercepted liquid is concentrated to 2 / 5 of the volume of the raw material liquid, the ultrafiltration is stopped, and the intercepted liquid and permeate are collected for detection.

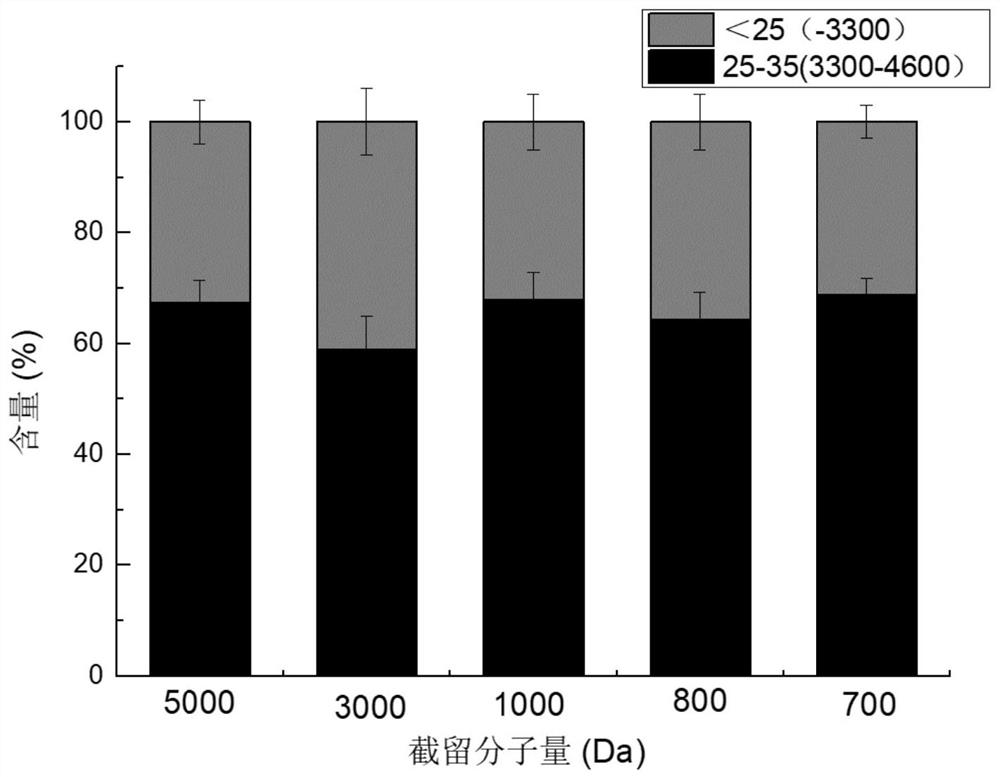

[0050] The cut-off liquid that embodiment 3 obtains and see through liquid are carried out performance test, and test result is as follows table 1 and image 3 Shown:

[0051] The test result of table 1 embodiment 3

[0052]

[0053] It can be seen from Table 1 that the comprehensive performance of the plate membrane with a molecular weight cut off of 3000 is the best, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com