3D printing porous zirconium oxide ceramic and preparation method thereof

A zirconia ceramic, 3D printing technology, applied in ceramic products, ceramic molding machines, manufacturing tools, etc., can solve the problems of high pore connectivity and high porosity, and achieve high pore connectivity, high porosity, and large surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of 3D printing porous zirconia ceramics, comprising the following steps:

[0031] Mixing main ingredients and dispersant to obtain ceramic slurry;

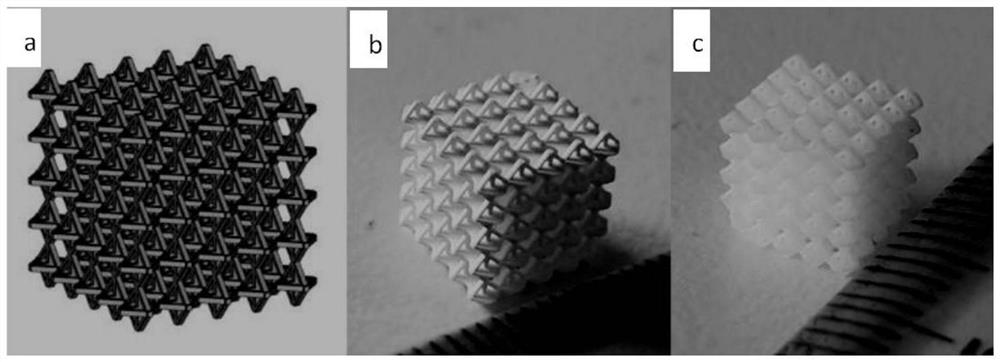

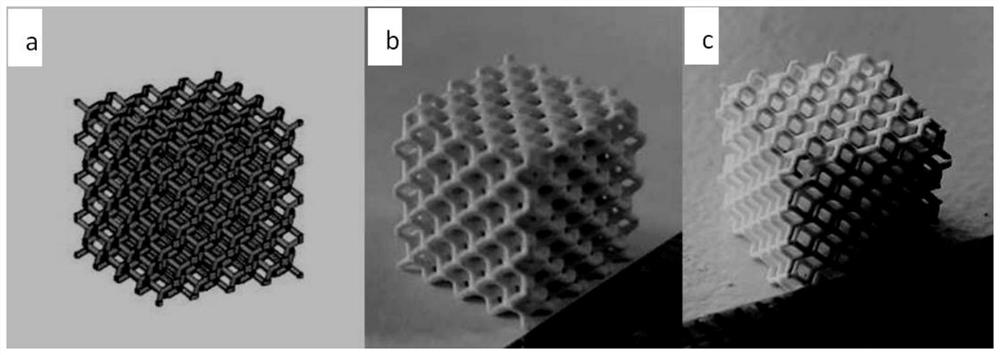

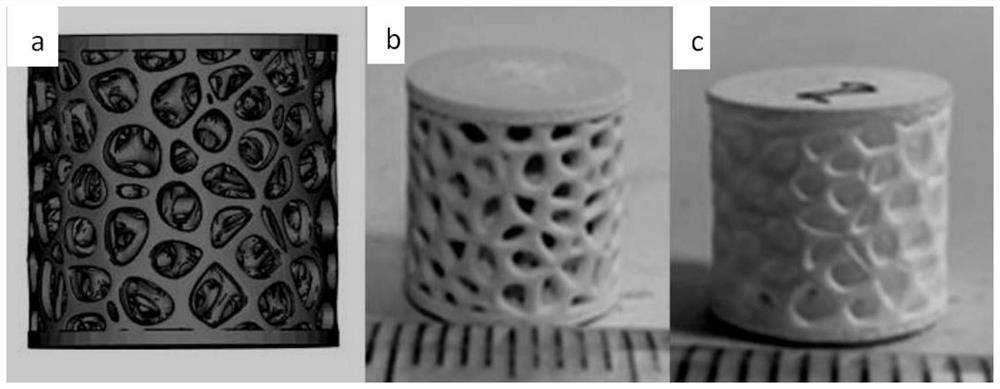

[0032] 3D modeling software is used to construct the parameters of the 3D model of porous zirconia ceramics, and the ceramic slurry is subjected to light-cured 3D printing to obtain a porous zirconia ceramic green body;

[0033] The porous zirconia ceramic green body is subjected to high-temperature debinding and sintering to obtain 3D printed porous zirconia ceramics;

[0034] The main ingredients include the following components in mass percentage: 20-90% of zirconia powder, 10-80% of photosensitive resin premix; the particle size of the zirconia powder is less than 100 μm;

[0035] The exposure intensity of the photocuring 3D printing is 10-500mw / cm 2 , the exposure time is 1-60s, and the paving thickness is 20-500μm;

[0036] The process of high-temperature debinding and si...

Embodiment 1

[0060] In this embodiment, the raw materials of the ceramic slurry include the following components in mass percentage: 99% of the main material, 1% of the dispersant (sodium polyacrylate);

[0061] Among them, the main material includes the following components in mass percentage: 60% of zirconia powder, 40% of photosensitive resin premix, wherein the photosensitive resin premix is a mixture of photosensitive resin and initiator, and the photosensitive resin is polyether acrylate and Polyester acrylate, the mass ratio of polyether acrylate and polyester acrylate is 1:1; Photoinitiator is (2,4,6-trimethylbenzoyl) diphenylphosphine oxide); The photosensitive The mass ratio of resin and photoinitiator is 99:1;

[0062] Composition of zirconia powder: ZrO 2 90wt%, Y 2 o 3 4.5wt%, Ce 2 o 3 3wt%, MgO content 2.5wt%; particle size of zirconia powder 50 0.33μm, D 90 1.1 μm;

[0063] Add the zirconia powder and photosensitive resin premix into a homogenizer, homogenize at a s...

Embodiment 2

[0071] In this embodiment, the raw materials of the ceramic slurry include the following components in mass percentage: main ingredient 99%, dispersant (polyammonium methacrylate) 1%;

[0072] Among them, the main material includes the following components in mass percentage: 70% of zirconia powder, 30% of photosensitive resin premix, wherein the photosensitive resin premix is a mixture of photosensitive resin and initiator, and the photosensitive resin is polyether acrylate and Epoxy acrylate, the mass ratio of polyether acrylate and epoxy acrylate is 1:1; Photoinitiator is phenyl bis (2,4,6-trimethylbenzoyl) phosphine oxide); The photosensitive The mass ratio of resin and photoinitiator is 98.5:1.5;

[0073] Composition of zirconia powder: ZrO 2 88wt%, Y 2 o 3 4.5wt%, Ce 2 o 3 3.5wt%, MgO content 4wt%; particle size of zirconia powder 50 0.29μm, D 90 0.9 μm;

[0074] Add the zirconia powder and photosensitive resin premix into a homogenizer, homogenize at a speed of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com