A kind of asiaticoside-chitosan-sodium alginate microsphere, preparation method and application thereof

A technology of asiaticoside and sodium alginate, which is applied in the field of biomedical materials, can solve the problems of low bioavailability and toxicity, and achieve the effects of good biocompatibility, high encapsulation rate and good sustained release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

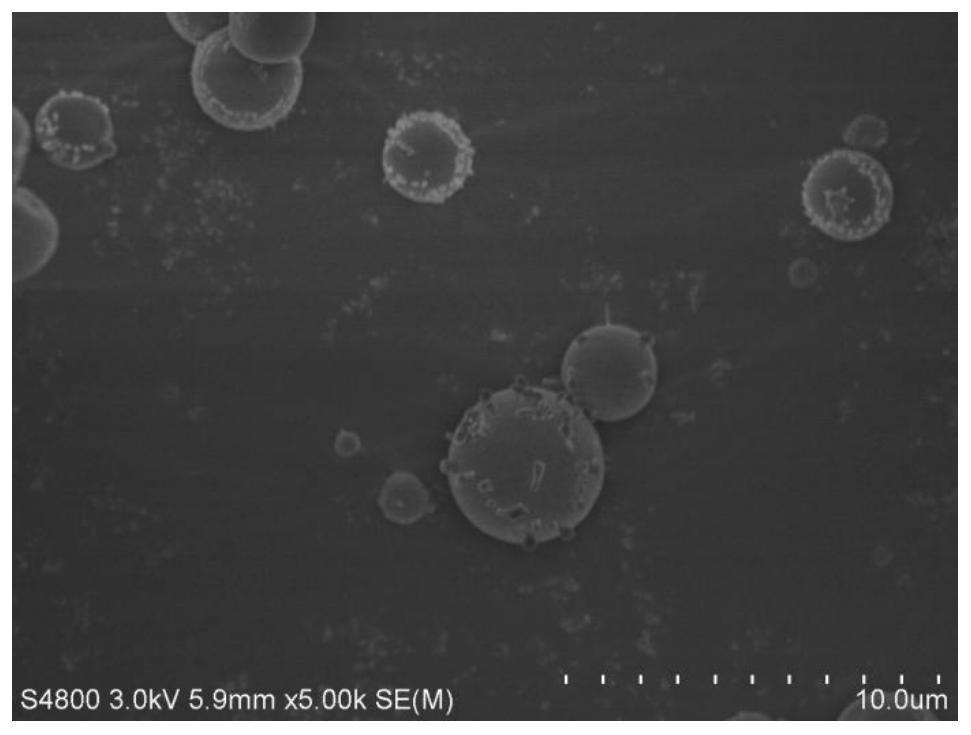

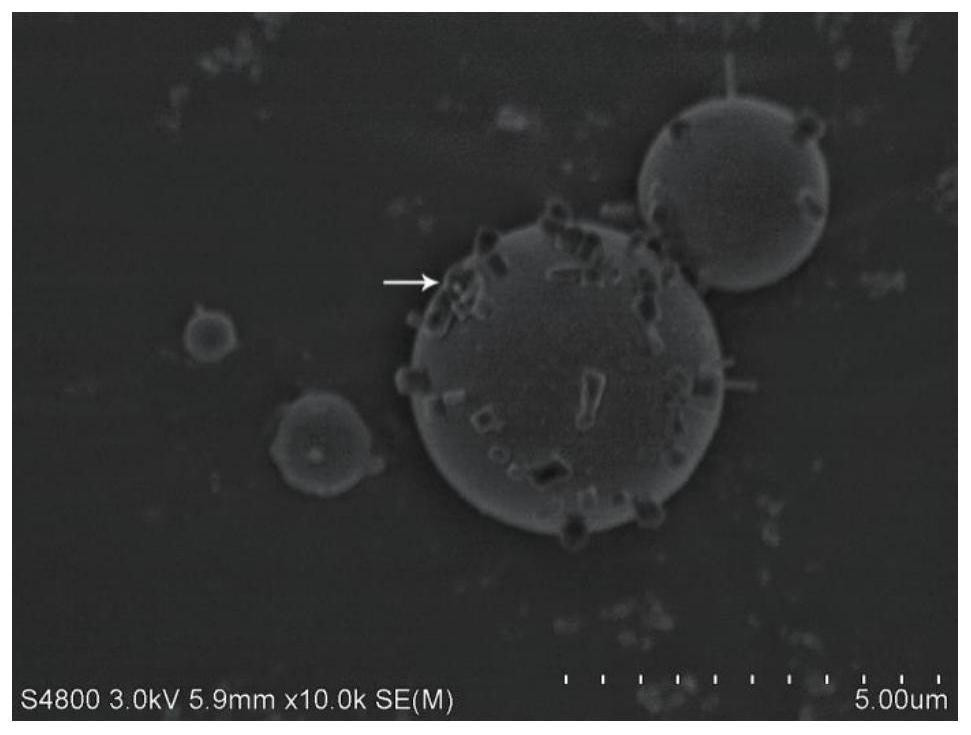

Image

Examples

Embodiment 1

[0039](a) taking 1g chitosan and adding to 100mL volume fraction is 2% glacial acetic acid solution to dissolve chitosan, preparation-chitosan acetic acid solution; the asiaticoside of 0.6g is dissolved with dehydrated alcohol to obtain product Madecassoside solution; mix the above two solutions, stir well, and add 2g of anhydrous calcium chloride to obtain the asiaticoside-chitosan acetic acid solution containing calcium chloride; use pure water Dissolve 1g of sodium alginate to obtain an aqueous solution of sodium alginate;

[0040] (b) slowly and evenly drop the prepared sodium alginate solution into the oil phase, and stir at 800rpm for 30min to form colostrum;

[0041] (c) slowly and evenly drop the asiaticoside-chitosan acetic acid solution containing calcium chloride into the colostrum, stir at a high speed of 1000 rpm, and fully emulsify for 1 hour;

[0042] (d) Slowly and evenly add 1ml of glyceraldehyde solution dropwise, after cross-linking and solidification for 1...

Embodiment 2

[0044] (a) Weighing 1g chitosan and adding it to 100mL volume fraction of 1% glacial acetic acid solution dissolves chitosan to prepare chitosan acetic acid solution; 0.4g asiaticoside is dissolved with absolute ethanol to obtain snow asiatica Grass glycoside solution; mix the above two solutions, stir evenly, until the ethanol is volatilized, add 2g of anhydrous calcium chloride to obtain the asiaticoside-chitosan acetic acid solution containing calcium chloride; dissolve with pure water 1g of sodium alginate to obtain an aqueous solution of sodium alginate;

[0045] (b) slowly and evenly drop the prepared sodium alginate solution into the oil phase, and stir at 500rpm for 40min to form colostrum;

[0046] (c) slowly and evenly drop the asiaticoside-chitosan acetic acid solution containing calcium chloride into the colostrum, stir at a high speed of 3000 rpm, and fully emulsify for 1 hour;

[0047] (d) Slowly and evenly add 1ml of glyceraldehyde solution dropwise, after cros...

Embodiment 3

[0049] (a) Weighing 1g chitosan and adding to 100mL volume fraction of 3% glacial acetic acid solution dissolves chitosan to prepare chitosan acetic acid solution; 0.6g asiaticoside is dissolved with absolute ethanol to obtain snow asiatica Grass glycoside solution; mix the above two solutions, stir evenly, until the ethanol is volatilized, add 2g of anhydrous calcium chloride to obtain the asiaticoside-chitosan acetic acid solution containing calcium chloride; dissolve with pure water The sodium alginate of 1.5g makes sodium alginate aqueous solution;

[0050] (b) slowly and evenly drop the prepared sodium alginate solution into the oil phase, and stir at 700rpm for 20min to form colostrum;

[0051] (c) slowly and evenly drop the asiaticoside-chitosan acetic acid solution containing calcium chloride into the colostrum, stir at a high speed of 3000 rpm, and fully emulsify for 1 hour;

[0052] (d) Slowly and evenly drop 2ml of glyceraldehyde solution, after cross-linking and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

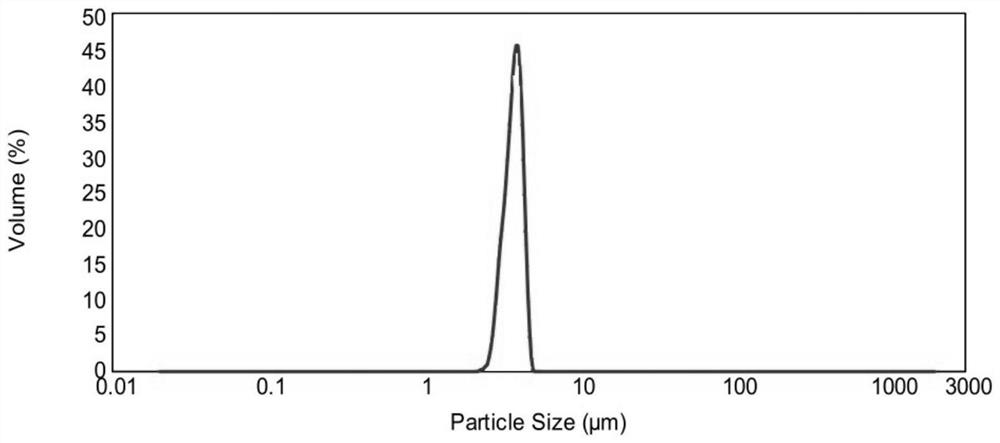

| particle diameter | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com