Complex iron desulfurization catalyst and preparation method thereof

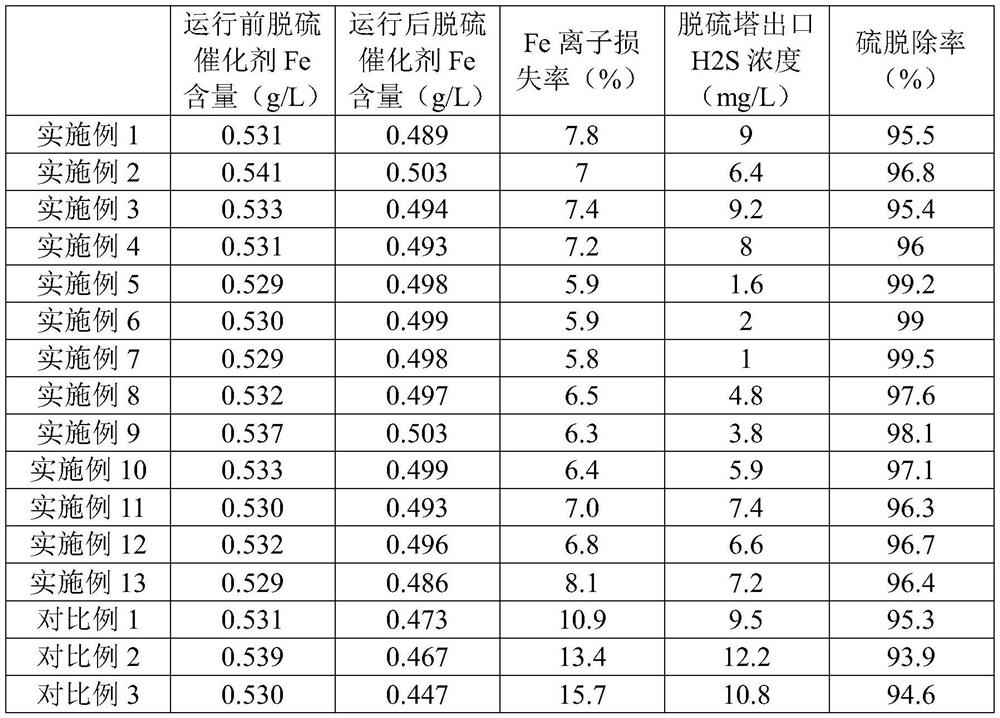

A desulfurization catalyst and complex iron technology, applied in the field of gas purification, can solve the problems of high difficulty in desulfurization wastewater treatment, corrosion of desulfurization equipment, high loss rate of Fe ions, etc., to avoid corrosion of desulfurization equipment, low loss rate, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Synthesis of iron-based double metal hydroxide: Dissolve ferric nitrate, urea and copper sulfate in water to obtain solution I, and stir and heat the solution I at 60° C. for 2.5 hours to obtain iron-based double metal hydroxide. The molar ratio of urea to ferric nitrate is 20:1, and the molar ratio of Fe to Cu is 100:1.

[0036]Synthesis of desulfurization catalyst: 2.5 parts by weight of N-(2-hydroxyethyl)ethylenediamine-N,N',N'triacetic acid, 0.01 parts by weight of polyethylene glycol ether and 0.01 parts by weight of sodium dodecyl sulfonate 1 part was dissolved in water to obtain solution II; while stirring, 1.5 parts by weight of freshly prepared iron-based double metal hydroxide was slowly added to the solution II in 4 times to obtain solution III;2CO3Adjust the pH of solution III to 8.

Embodiment 2

[0038]Synthesis of iron-based double metal hydroxide: Dissolve ferric chloride, urea and nickel sulfate in water to obtain solution I, and stir and heat the solution I at 70° C. for 3.5 hours to obtain iron-based double metal hydroxide. The molar ratio of urea to ferric nitrate is 15:1, and the molar ratio of Fe to Ni is 70:1.

[0039]Synthesis of desulfurization catalyst: 3 parts by weight of 1,3-propanediamine-N,N,N',N'-tetraacetic acid, 0.01 parts by weight of polyethylene glycol ether and 0.01 parts by weight of sodium p-toluenesulfonate are dissolved in water Obtain solution II; while stirring, add 2 parts by weight of freshly prepared iron-based double metal hydroxide slowly and 4 times into the solution II to obtain solution III; use KHCO3Adjust the pH of solution III to 8.

Embodiment 3

[0041]The amount of 1,3-propanediamine-N,N,N',N'-tetraacetic acid is 2.5 parts by weight, the amount of freshly prepared iron-based double metal hydroxide is 1.5 parts by weight, and the remaining steps are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com