Liquid conditioner based on improvement of soil secondary salinization and preparation method thereof

A technology for secondary salinization and soil improvement, applied in soil conditioning materials, chemical instruments and methods, liquid fertilizers, etc., to achieve the effects of enhancing salt resistance, soil fertility, and buffering capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

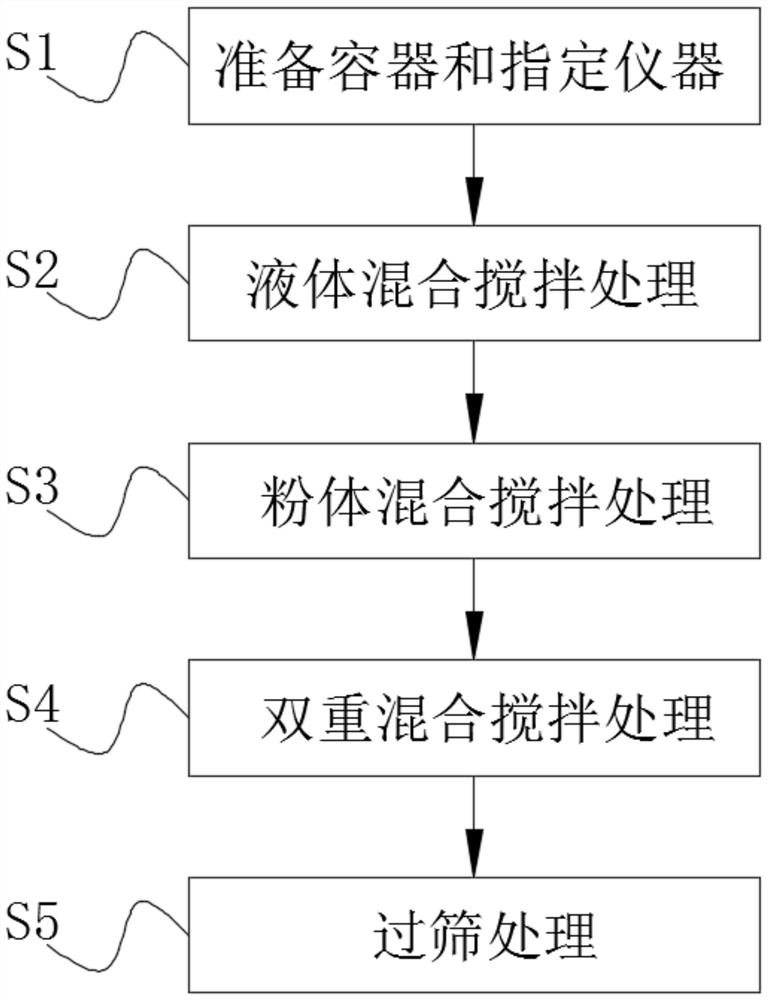

Method used

Image

Examples

Embodiment 1

[0026] A liquid conditioner based on improving secondary salinization of soil, consisting of the following raw materials in parts by weight: 40 parts of water, 10 parts of biochar, 1 part of Bacillus amyloliquefaciens BS211 bacterial agent, 2 parts of humus liquid, and 5 parts of bone meal 5 parts of plant nutrient solution, 20 parts of nanoscale dolomite powder, 2 parts of sugar alcohol, 5 parts of potassium silicate, 5 parts of biochemical potassium fulvic acid, 10 parts of low-salt organic fertilizer, and 5 parts of pH regulator.

[0027] Further, the low-salt organic fertilizer is prepared by crushing and mixing three kinds of calcium sulfite, desulfurized gypsum and phosphogypsum, and the mixing ratio is 1:1:1.

[0028] Further, the bacterial agent of Bacillus amyloliquefaciens BS211 is a facultative anaerobic bacterium, showing light yellow opaque colonies, and the culture temperature is controlled at 31°C.

[0029] Further, the humic liquid is formed by stirring and mix...

Embodiment 2

[0038]A liquid conditioner based on improving soil secondary salinization, consisting of the following raw materials in parts by weight: 45 parts of water, 15 parts of biochar, 3 parts of Bacillus amyloliquefaciens BS211 bacterial agent, 3.5 parts of humus liquid, and 6.5 parts of bone meal 7 parts of plant nutrient solution, 25 parts of nanoscale dolomite powder, 3.5 parts of sugar alcohol, 10 parts of potassium silicate, 7 parts of biochemical potassium fulvic acid, 15 parts of low-salt organic fertilizer, and 7 parts of pH regulator.

[0039] Further, the low-salt organic fertilizer is prepared by crushing and mixing three kinds of calcium sulfite, desulfurized gypsum and phosphogypsum, and the mixing ratio is 1:1:1.

[0040] Further, the bacterial agent of Bacillus amyloliquefaciens BS211 is a facultative anaerobic bacterium, showing light yellow opaque colonies, and the culture temperature is controlled at 34°C.

[0041] Further, the humic liquid is formed by stirring and...

Embodiment 3

[0050] A liquid conditioner based on improving secondary salinization of soil, consisting of the following raw materials in parts by weight: 50 parts of water, 20 parts of biochar, 5 parts of Bacillus amyloliquefaciens BS211 bacterial agent, 5 parts of humus liquid, and 8 parts of bone meal 10 parts of plant nutrient solution, 30 parts of nano-scale dolomite powder, 5 parts of sugar alcohol, 15 parts of potassium silicate, 10 parts of biochemical potassium fulvic acid, 20 parts of low-salt organic fertilizer, and 10 parts of pH regulator.

[0051] Further, the low-salt organic fertilizer is prepared by crushing and mixing three kinds of calcium sulfite, desulfurized gypsum and phosphogypsum, and the mixing ratio is 1:1:1.

[0052] Further, the bacterial agent of Bacillus amyloliquefaciens BS211 is a facultative anaerobic bacterium, showing light yellow opaque colonies, and the culture temperature is controlled at 37°C.

[0053] Further, the humic liquid is formed by stirring a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com