A kind of biomass formaldehyde-free adhesive and its preparation and application method

The technology of an aldehyde adhesive and an application method is applied in the field of biomass aldehyde-free adhesive and its preparation and application. The effect of promoting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

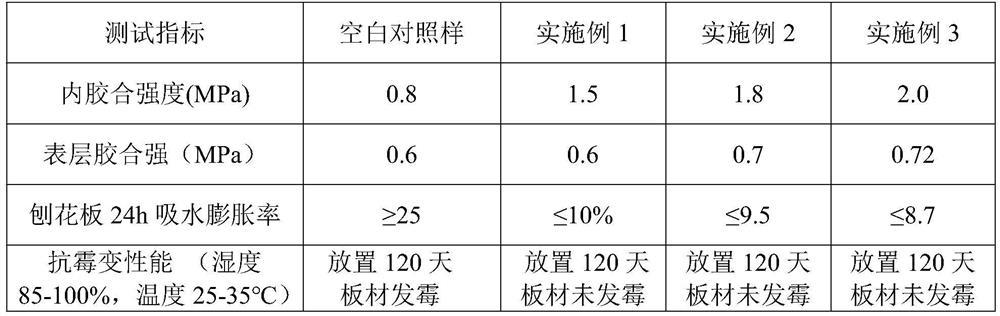

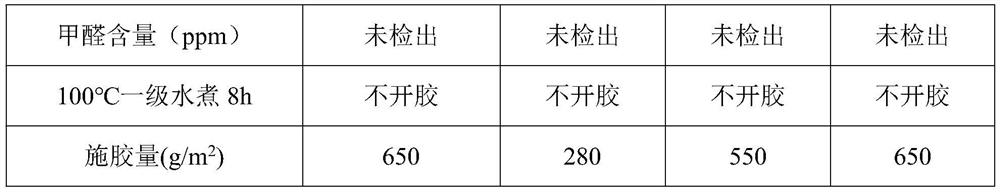

Embodiment 1

[0031] The preparation and application method of a kind of biomass formaldehyde-free adhesive of the present invention specifically comprises the following steps:

[0032] (1) Firstly, dry the pre-prepared papaya leaves at an ambient temperature of 25-35°C for 1-2 weeks, then place them in a high-temperature oven for 8 hours at 100-110°C, and control their moisture content at 5 % or less, then use a four-cutter high-speed pulverizer to pulverize it at a rate of 10000-15000 rpm for 10min, and filter it with a 200-mesh filter screen to obtain a coarse plant fiber powder, and use a ball mill for 25-30min to filter the coarse particle residue 1 Finally, it is taken out as plant fiber residue filling powder for later use. Mix and stir the 5 mass parts of plant fiber coarse material powder obtained above and the fiber solvent activation system according to the mass ratio of solid to liquid 0.5:5, wherein the fiber solvent activation system consists of 48 mass parts nitrogen methyl m...

Embodiment 2

[0040] The preparation and application method of a kind of biomass formaldehyde-free adhesive of the present invention specifically comprises the following steps:

[0041] (1) First, dry the pre-prepared bamboo leaves at an ambient temperature of 25-35°C for 1-2 weeks, then place them in a high-temperature oven at 100-120°C for 10 hours, and control their moisture content at 5 % or less, then use a four-blade high-speed pulverizer to pulverize it at a rate of 15000-20000 rpm for 10min, and filter it with a 200-mesh filter screen to obtain the plant fiber coarse material powder, and use a ball mill for 25-30min for the coarse particle residue after filtering Finally, it is taken out as plant fiber residue filling powder for later use. Mix and stir the 5 mass parts of plant fiber coarse material powder obtained above and the fiber solvent activation system according to the mass ratio of 2:35, wherein the fiber solvent activation system consists of 135 mass parts of nitrogen meth...

Embodiment 3

[0049] The preparation and application method of a kind of biomass formaldehyde-free adhesive of the present invention specifically comprises the following steps:

[0050] (1) First, dry the pre-prepared ramie at an ambient temperature of 25-35°C for 1-2 weeks, then place it in a high-temperature oven at 100-110°C for 8 hours, and control its moisture content at 5% Next, use a four-cutter high-speed pulverizer to pulverize it at a rate of 15000-18000 rpm for 10 minutes, and filter it with a 200-mesh filter screen to obtain a coarse plant fiber powder. Take it out and use it as plant fiber residue to fill the powder for later use. Mix and stir the 5 mass parts of plant fiber coarse material powder obtained above and the fiber solvent activation system according to the mass ratio of solid-liquid 5:100, wherein the fiber solvent activation system consists of 75 parts by mass of nitrogen methyl morpholine oxide and 5 parts by mass of dimethyl sulfoxide, 15 parts by mass of NN dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com