Novel magnetic aluminum-based composite material and preparation method and application thereof

An aluminum-based composite material, magnetic technology, applied in the direction of magnetic materials, magnetic objects, inductance/transformer/magnet manufacturing, etc., can solve the conclusion and mechanism is not clear and systematic, the magnetic material is not perfect, limit the NdFeB Application fields and other issues, to achieve the effect of preventing uneven material structure, reducing sintering time, and short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

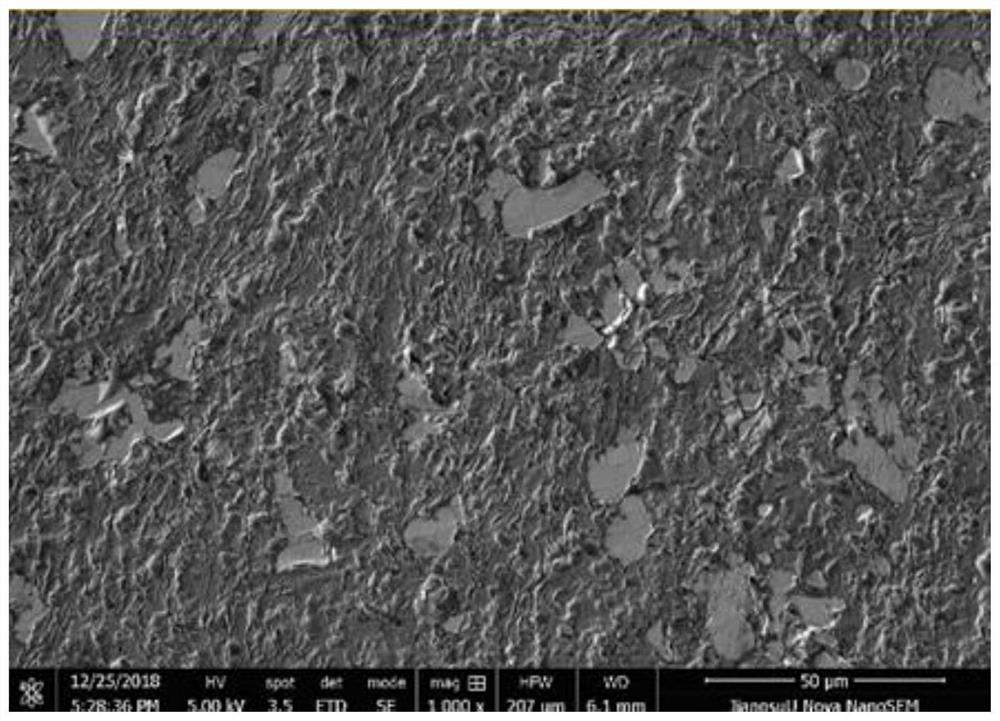

Embodiment 1

[0040] The matrix material of the novel aluminum matrix composite material of this embodiment is 2024 aluminum alloy, and the composition of composite phase is: NdFeB powder 17.5wt.%, Co 2.4wt.%, Ni 2%, rare earth Sm 0.2wt.%. The powder of the composite phase and the base phase 2024 aluminum alloy powder are mixed in proportion. Composite materials were then prepared as follows:

[0041] (1) High energy ball mill

[0042] Adopt the method of graded ball milling, that is, firstly grind large-sized NdFeB, aluminum powder, cobalt powder and samarium powder at high speed respectively. 3:2:1, the ratio of alcohol to powder is 3:5, and the ball milling time is 15 hours. Then the ball-milled powder is carried out in a low-speed ball mill according to the design ratio to achieve uniform material mixing. The material ratio is 3:5.

[0043] (2) Magnetic field static pressure forming

[0044] The ball-milled powder was pressed under isostatic pressure of 300MPa for 30 minutes, and t...

Embodiment 2

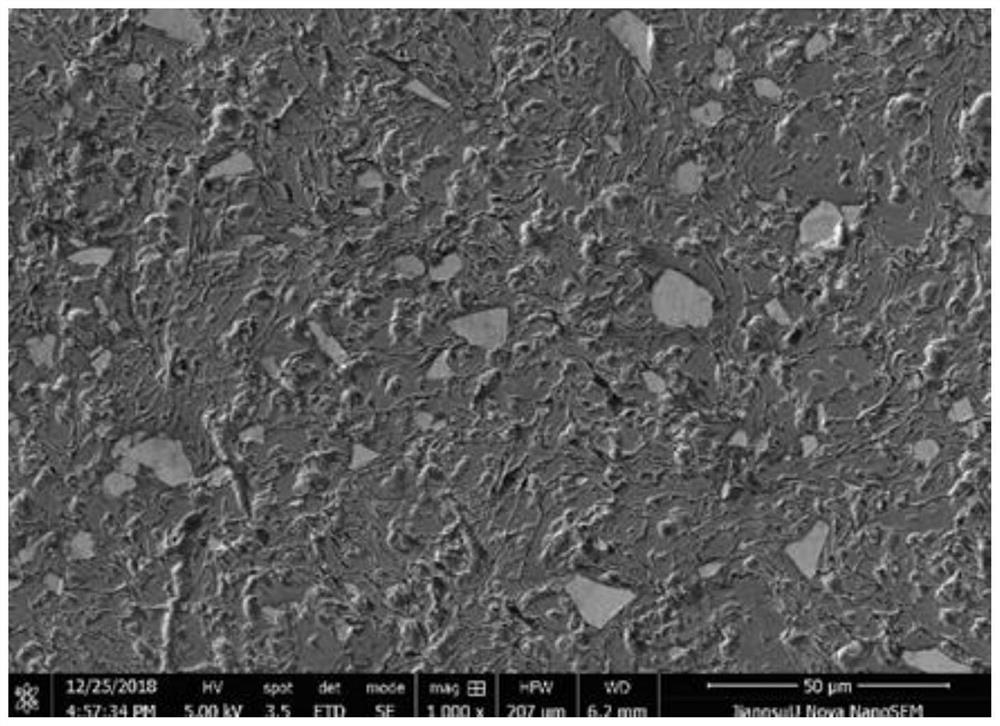

[0054] The base material of the novel aluminum-based composite material in this embodiment is 2024 aluminum alloy, and the composition of the composite phase is: NdFeB powder 18wt.%, Co 4.8wt.%, Ni 4%, rare earth Sm 0.4wt.%. The powder of the composite phase and the 2024 aluminum alloy powder of the base phase are mixed in proportion. Composite materials were then prepared as follows:

[0055] (1) High energy ball mill

[0056] Adopt the method of graded ball milling, that is, firstly grind large-sized NdFeB, aluminum powder, cobalt powder and samarium powder at high speed respectively. 3:2:1, the ratio of alcohol to powder is 3:5, and the ball milling time is 15 hours. Then the ball-milled powder is carried out in a low-speed ball mill according to the design ratio to achieve uniform material mixing. The material ratio is 3:5.

[0057] (2) Magnetic field static pressure forming

[0058] The ball-milled powder was pressed and formed under isostatic pressure conditions of ...

Embodiment 3

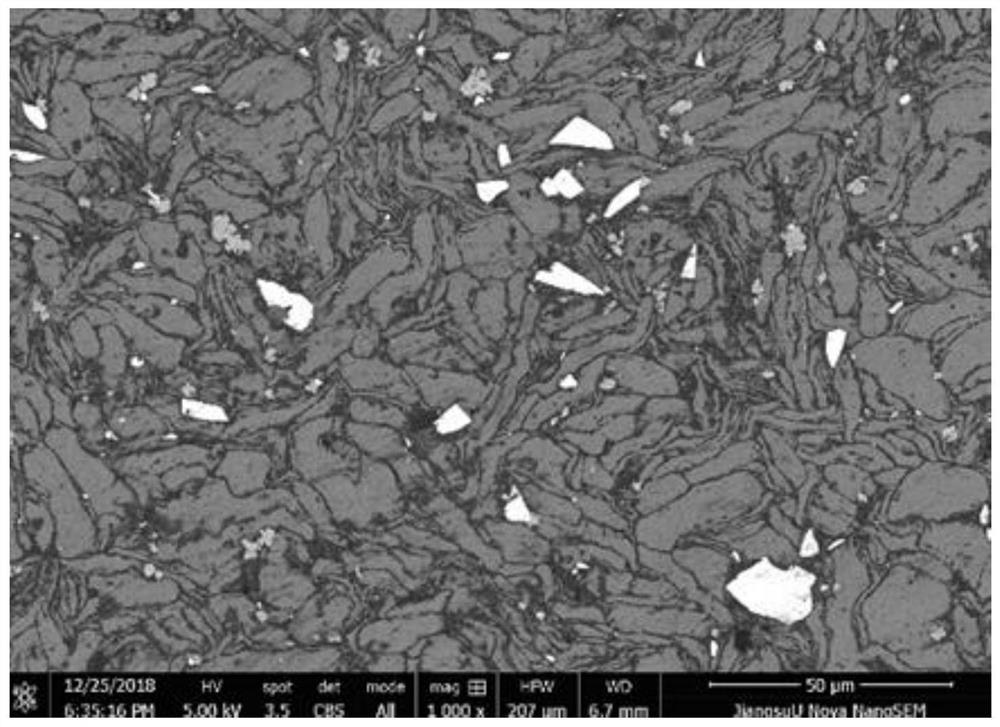

[0068] The matrix material of the novel aluminum-based composite material in this embodiment is 2024 aluminum alloy, and the composition of the composite phase is: NdFeB powder 20.6wt.%, Co 7.2wt.%, Ni 6%, rare earth Sm 0.6wt.%. The powder of the composite phase and the base phase 2024 aluminum alloy powder are mixed in proportion. Composite materials were then prepared as follows:

[0069] (1) High energy ball mill

[0070] Adopt the method of graded ball milling, that is, firstly grind large-sized NdFeB, aluminum powder, cobalt powder and samarium powder at high speed respectively. 3:2:1, the ratio of alcohol to powder is 3:5, and the ball milling time is 15 hours. Then the ball-milled powder is carried out in a low-speed ball mill according to the design ratio to achieve uniform material mixing. The material ratio is 3:5.

[0071] (2) Magnetic field static pressure forming

[0072] The ball-milled powder was pressed into shape under the condition of 300MPa isostatic pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com